Desulfurizing agent and preparation method thereof

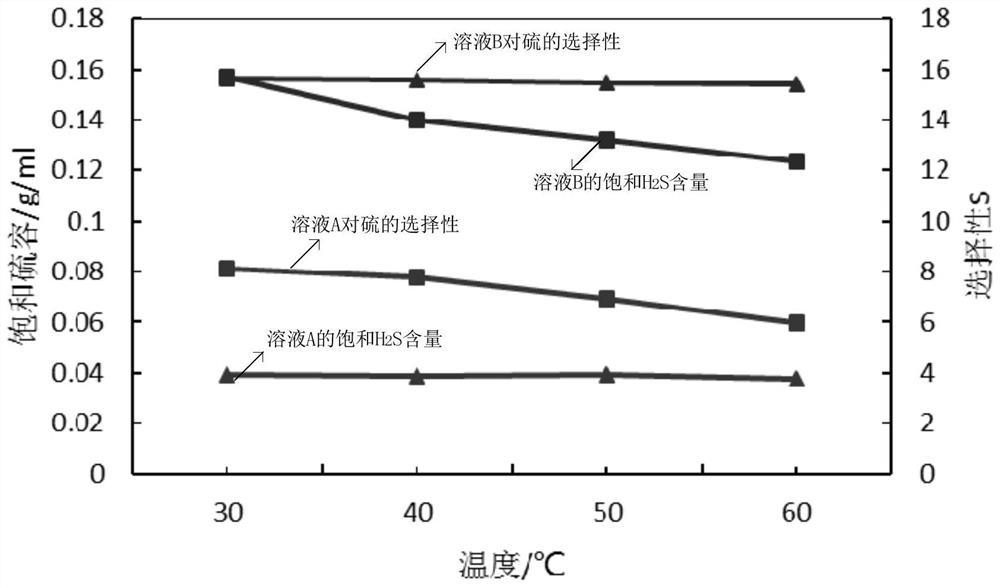

A desulfurizing agent and group technology, applied in the field of desulfurizing agent and its preparation, can solve the problems of unprotected production equipment, poor selectivity, lack of anti-corrosion ability, etc., and achieve the effects of avoiding corrosion, reducing alkalinity and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] On the one hand, the embodiment of the present invention also provides a method for preparing a desulfurizer, the method comprising: adding a sterically hindered amine into water according to the mass percentage of each component, heating to a reference temperature, and stirring at a reference speed for a reference time to obtain Desulfurizer.

[0077] Optionally, the reference temperature is 20-25°C.

[0078] By preparing the desulfurizing agent at a temperature of 20-25°C, it is possible to avoid side reactions due to too high temperature, or uneven mixing of the desulfurizing agent due to too low temperature. Exemplary temperatures for preparation may be 20°C, 21°C, 22°C, 23°C, 24°C, 25°C, and the like.

[0079] Optionally, the reference time is 10-30 minutes.

[0080] By setting the stirring time, the steric hindered amine can be mixed uniformly to obtain a desulfurizer with uniform composition. Exemplary stirring times may be 10 minutes, 11 minutes, 12 minutes, ...

Embodiment 1

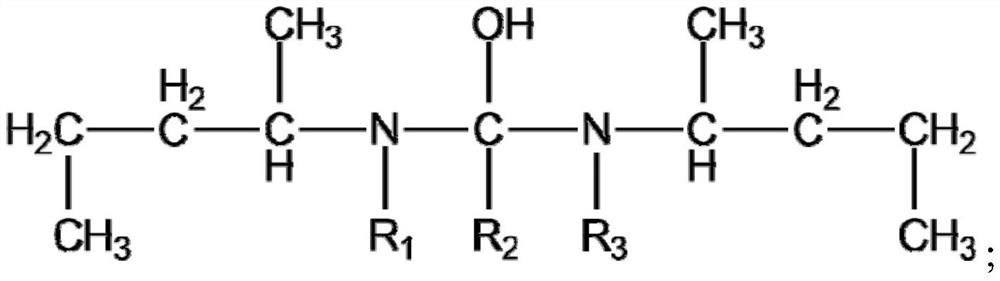

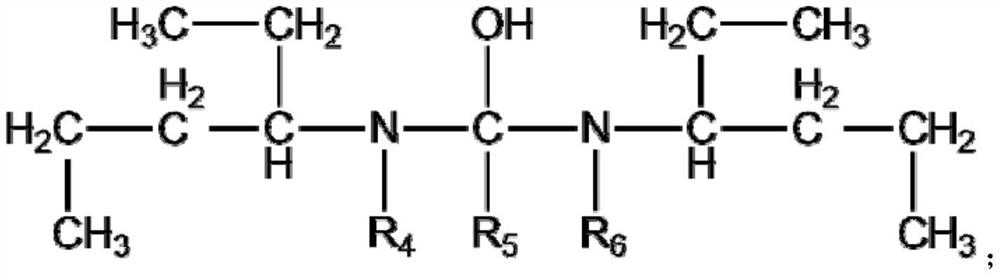

[0086] Add 30% C to the water 11 h 25 ON 2 、C 12 h 27 ON 2 with C 16 h 36 ON 2 , stirred at a speed of 30 r / min for 10 minutes at a temperature of 20° C. to obtain the desulfurizing agent provided in the examples of the present invention.

Embodiment 2

[0088] Add 38% C to the water 16 h 36 ON 2 、C 17 h 38 ON 2 with C 11 h 26 ON 2 , at a temperature of 21° C., stirring at a speed of 31 r / min for 16 minutes, to obtain the desulfurizing agent provided by the embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com