A kind of activated carbon preparation process

A technology of activated carbon preparation and activated carbon, which is applied in the fields of manufacturing tools, carbon compounds, inorganic chemistry, etc., can solve the problems of shortening the service life of molds, waste of activated carbon raw materials, corrosion, etc., and achieve the effect of shortening the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

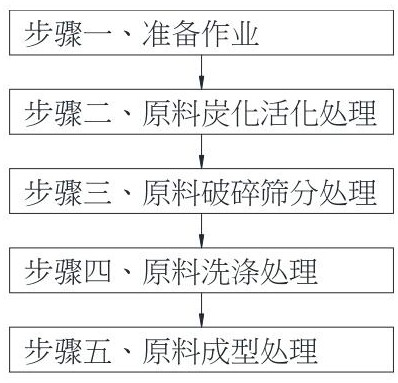

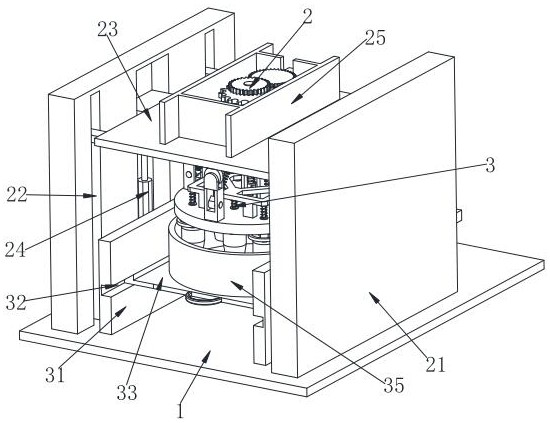

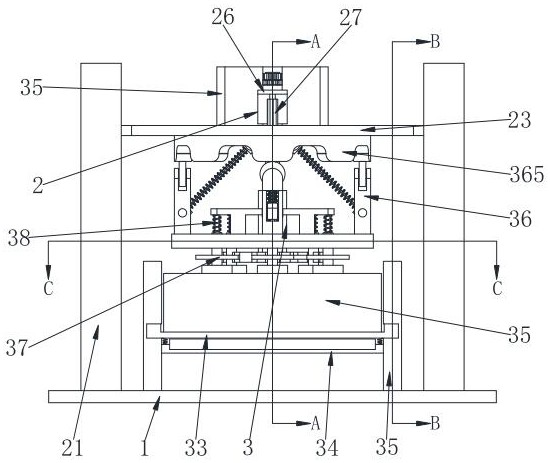

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0033] A kind of activated carbon preparation process, it has used a kind of activated carbon preparation equipment, this activated carbon preparation equipment comprises base 1, drive unit 2 and preparation device 3, when adopting above-mentioned activated carbon preparation equipment to prepare activated carbon, specific method is as follows:

[0034] Step 1. Preparatory work: Debug the activated carbon preparation equipment, and conduct preliminary pre-selection and screening of the raw materials for making activated carbon;

[0035]Step 2. Raw material carbonization activation treatment: heat the raw material in step 1. During the process of temperature rise, the thermal decomposition of raw material will occur, and the chemical composition will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com