High-crack-resistance foam concrete and preparation method thereof

A foamed concrete, high crack resistance technology, applied in the field of building materials, can solve the problems of large drying shrinkage, limited application of foamed concrete, low strength of foamed concrete, etc., and achieve the effect of improving drying shrinkage and cracking resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

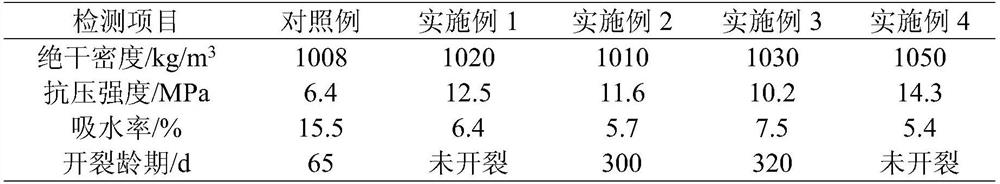

Examples

Embodiment approach 1

[0040] This embodiment provides a high-crack-resistant foam concrete, which consists of the following parts by mass: 1000 parts of cement, 300 parts of fly ash, 500 parts of slag powder, 2 parts of acrylic water-absorbing resin, 5 parts of nano-silica reinforced foaming agent, 300 parts of weakly alkaline water with PH=9, 900 parts of water, 360 parts of shale ceramsite smaller than 10mm and 8 parts of crop straw fiber.

[0041] The concrete preparation steps of above-mentioned high anti-cracking foam concrete are as follows:

[0042] 1) Stir the cement, fly ash, silica fume, water-absorbing resin and water at a speed of 90r / min for 30s in proportion;

[0043] 2) Gradually add shale ceramsite and crop straw fibers to the slurry prepared in step 1) and stir at a speed of 120r / min for 30s;

[0044] 3) Use nano-silica to enhance the foaming agent and PH = 9 weak alkaline water to form foam, and add it to the well-stirred slurry mixture and stir at a speed of 60r / min for 3 minute...

Embodiment approach 2

[0047] This embodiment provides a high-crack-resistant foam concrete, which consists of the following parts by mass: 1000 parts of cement, 100 parts of fly ash, 300 parts of slag powder, 3 parts of ammonium acrylate water-absorbing resin, and 2 parts of nano-zinc oxide reinforced foaming agent , 120 parts of weakly alkaline water with pH=9, 700 parts of water, 300 parts of rubber particles with a particle diameter less than 10mm and 5 parts of wood fiber.

[0048] The concrete preparation steps of above-mentioned high anti-cracking foam concrete are as follows:

[0049] 1) Stir the cement, fly ash, silica fume, water-absorbing resin and water at a speed of 90r / min for 30s in proportion;

[0050] 2) Gradually add rubber particles and wood fibers to the slurry prepared in step 1) and stir at a speed of 120r / min for 30s;

[0051] 3) Use nano-zinc oxide to enhance foaming agent and PH = 9 weak alkaline water to form foam, and add it to the well-stirred slurry mixture and stir at ...

Embodiment approach 3

[0054] This embodiment provides highly crack-resistant foam concrete, which consists of the following parts by mass: 800 parts of cement, 100 parts of fly ash, 200 parts of slag powder, 5 parts of methacrylamidopropyltrimethylammonium chloride water-absorbing resin, nano 4 parts of aluminum oxide reinforced foaming agent, 240 parts of weak alkaline water with pH=9, 500 parts of water, 200 parts of sand with particle diameter less than 10mm and 3 parts of hemp fiber.

[0055] The concrete preparation steps of above-mentioned high anti-cracking foam concrete are as follows:

[0056] 1) Stir the cement, fly ash, silica fume, water-absorbing resin and water at a speed of 90r / min for 30s in proportion;

[0057] 2) Gradually add sand and hemp fiber to the slurry prepared in step 1) and stir at a speed of 120r / min for 30s;

[0058] 3) Use nano-alumina to enhance the foaming agent and PH = 9 weak alkaline water to form foam, and add it to the well-stirred slurry mixture and stir at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com