Preparation method of organic sericite for anticorrosive coating

A technology of organic sericite and anti-corrosion coating, which is applied in anti-corrosion coatings, chemical instruments and methods, dyeing organosilicon compound treatment, etc., can solve the problem of complex graft modification process by chemical means and weak adsorption strength of physical coating modification , The improvement effect needs to be strengthened, etc., to achieve the effect of high degree of automation, shortened reaction time, and large product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the present embodiment, the specific steps of the preparation method of the organic sericite for anti-corrosion coating are as follows:

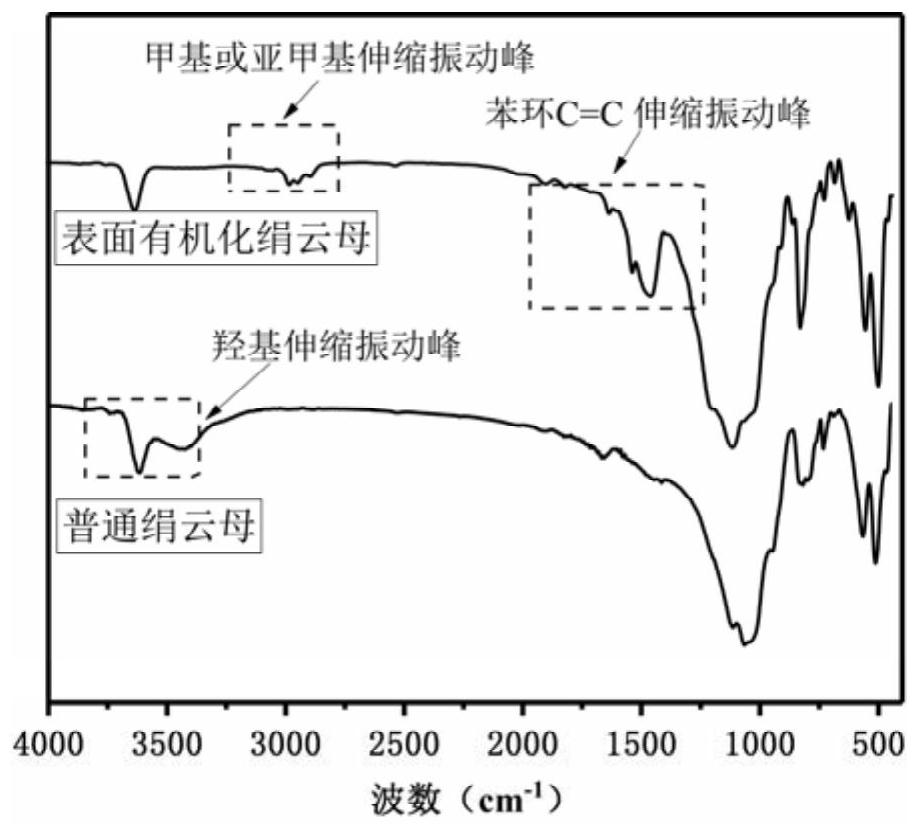

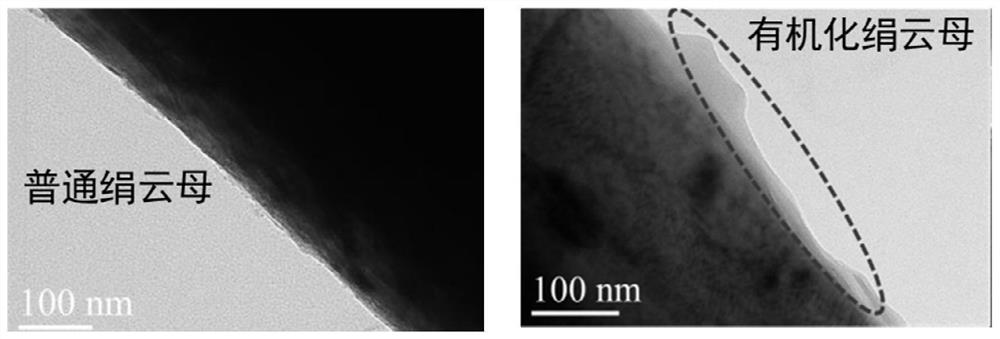

[0025] (1) Take the organic resin and add sericite filler to the organic resin, move it into the grinding tank after mixing and stirring evenly, and use high-temperature mechanical ball milling method to carry out organic treatment, and the obtained product is obtained after centrifugation, suction filtration and drying. Surface organic sericite powder;

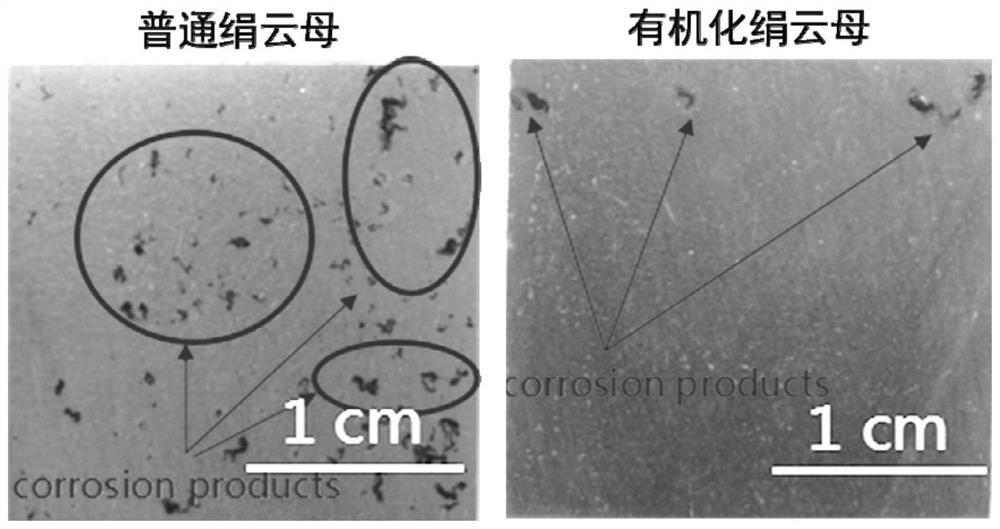

[0026] (2) Mix the surface-organized mica powder in step (1) with film-forming resin, additives, diluents and other fillers, and mix them mechanically to obtain component A, and at the same time take component B curing agent and component A ultrasonic stirring mixes, and makes described surface organic mica anticorrosion coating;

[0027] In step (1), the organic resin includes, but is not limited to, one of epoxy resin, silicone resin, and organic fluorine resin.

[0028] In st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com