New imitation tencel style fabric and dyeing and finishing process

A fabric and tencel technology, applied in dyeing, rayon manufacturing, filament/thread forming, etc., can solve problems such as many quality problems, high operation requirements, and low production efficiency, so as to achieve stable production quality and improve product quality , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

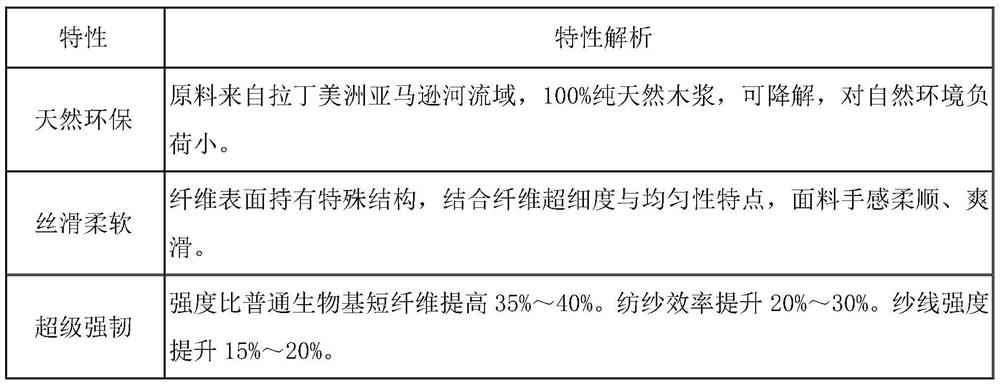

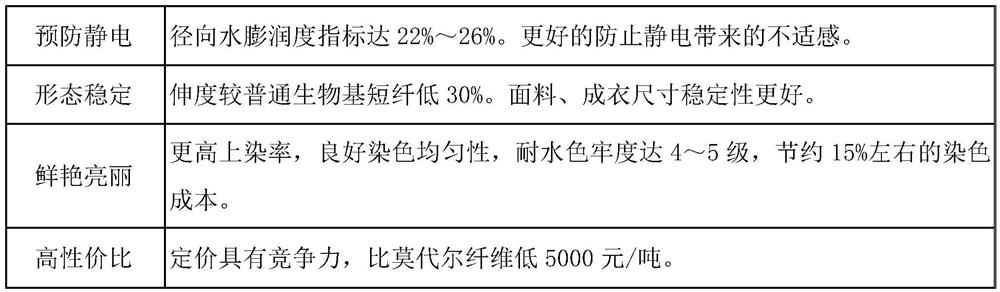

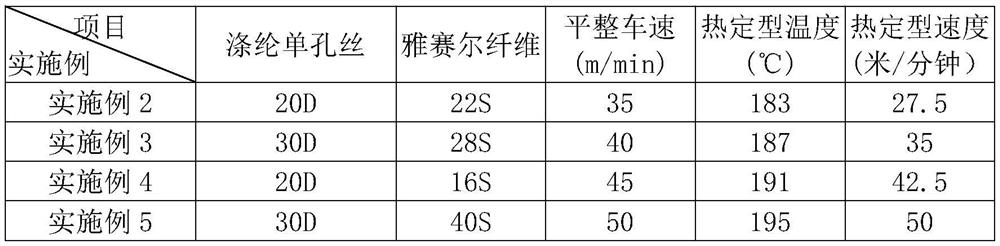

[0055] A novel tencel-like fabric disclosed by the invention is formed by interweaving warp threads and weft threads. The radial direction is polyester single-hole yarn, and its specification is 20D. The latitudinal direction is the new environmentally friendly cellulose fiber Yacell fiber, which is derived from the Chinese patent "New Cellulose Fiber Yacell Product and Its Processing Technology" with the patent publication number CN109355775A. The compact siro spinning method is adopted for spinning, and the specification of the yarn is 30S. The new Tencel-like fabric is woven on an air-jet loom with a plain weave.

[0056] The invention also discloses a novel dyeing and finishing process of imitation tencel fabric, comprising the following specific steps:

[0057] The first step, leveling: put the new tencel-like fabric in the leveling machine for leveling treatment. There are 9 water tanks in total, and the temperature is set to 38°C, 60°C, 70°C, 85°C, 93°C, and 93°C in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com