Dynamic high-resolution optical wavefront phase measurement method

A wavefront phase, high-resolution technology, applied in the optical field, can solve the problems of low resolution and low precision, and achieve the effects of good economy, high precision, and no subjective errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be further described below in conjunction with accompanying drawing.

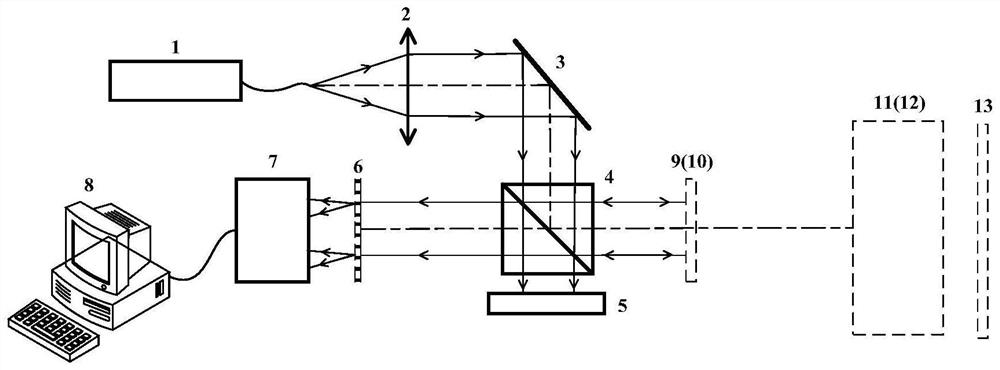

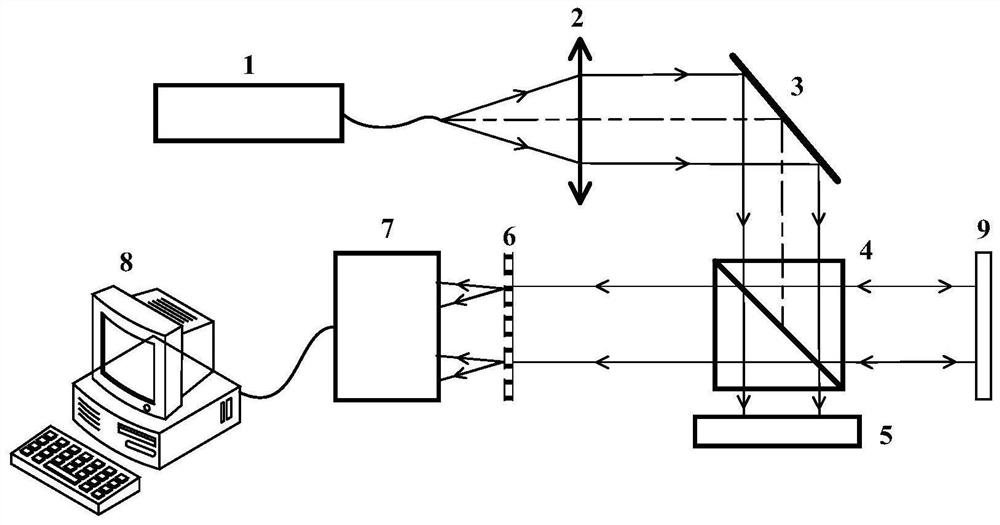

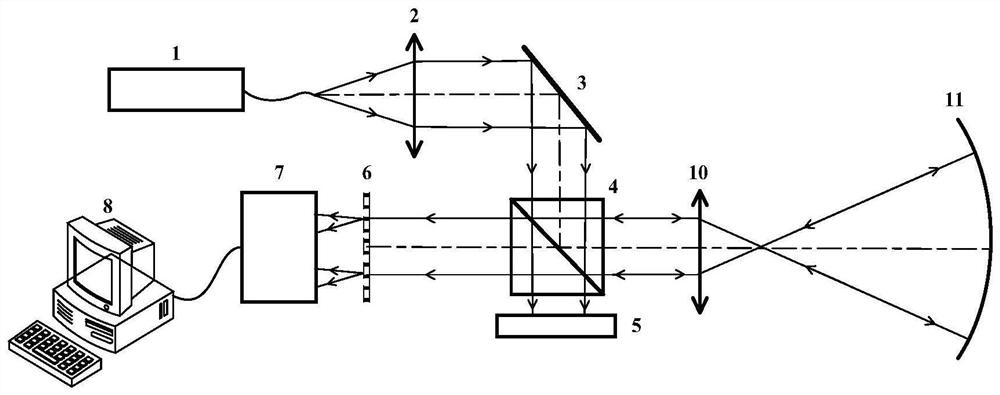

[0100] Such as figure 1 As shown, the dynamic high-resolution optical wavefront phase measurement device of the present invention consists of a laser 1, a collimating mirror 2, a plane mirror 3, a beam splitter 4, an absorber 5, a hybrid modulation grating 6, a detector 7, a computer 8, The calibration mirror 9, the standard lens 10 and the auxiliary standard flat mirror 13 are composed. figure 1 The dotted lines in the center are replaceable devices.

[0101] Laser 1, collimator 2, and plane reflector 3 are arranged sequentially along the same optical path; plane reflector 3 is used to deflect the output beam of collimator 2 onto beam splitter 4 to reduce the volume of the measuring device; beam splitter 4 is arranged on the output light path of the plane reflector 3; the beam splitter 4 transmits the output light beam of the plane reflector 3 and an absorber 5 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com