Rock inclusion slice moving device

A technology of inclusions and slices, applied in the fields of geological exploration and oil and gas exploration research, can solve the problems of long time period of moving slices, cracking or even breaking of rock slices, and unfavorable research, so as to maintain the original appearance, accelerate the dissolution rate, and improve the The effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

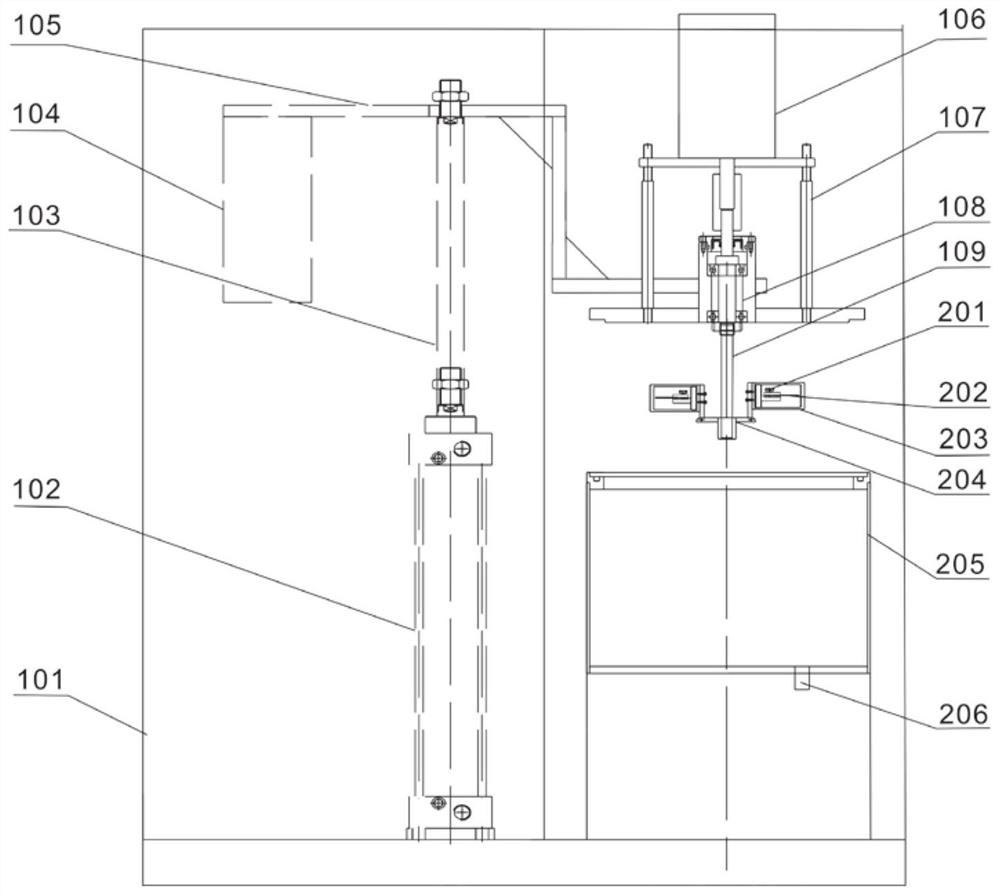

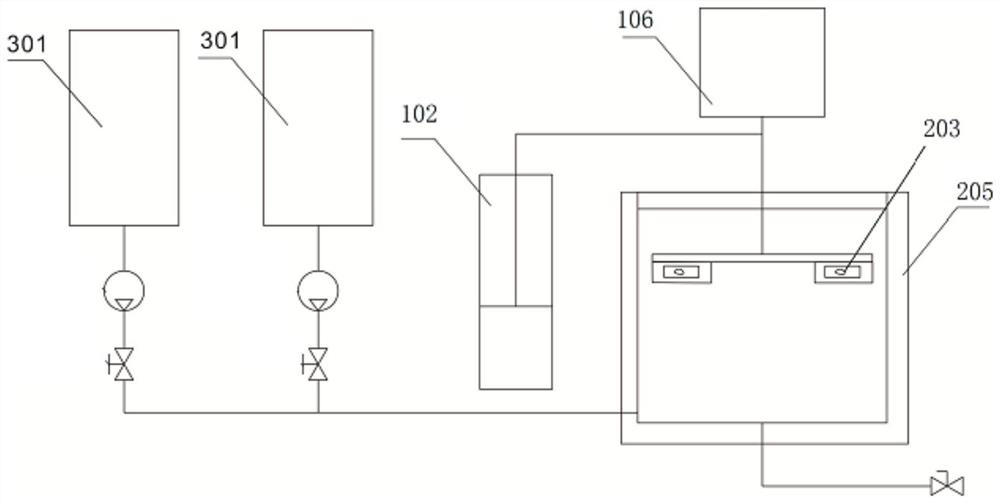

[0073] Such as Figures 1 to 2 As shown, the present invention provides a rock inclusion thin section moving device, comprising:

[0074] Chassis 101;

[0075] The cleaning box 205 is located in the cabinet 101 and is used to accommodate the solvent;

[0076] The sample cabin 203, the sample cabin 203 is arranged in the cabinet 101, and is used to accommodate rock inclusion thin slices, and the bulkhead of the sample cabin 203 is provided with openings;

[0077] The driving mechanism is used to drive the sample cabin 203 to lift and rotate, so that the sample cabin 203 enters, leaves and rotates in the cleaning box 205 .

[0078] In this embodiment, the drive mechanism includes:

[0079] Elevator 102, and elevator 102 comprises the lifting rod 103 that can expand and contract along vertical direction;

[0080] Lifting bracket 105, the lifting bracket 105 is connected to the top of the lifting rod 103;

[0081] The transmission bracket 107 is connected to one end of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com