Rock crack observation device and method

A technology of rock fractures and observation devices, applied in the directions of measuring devices, analysis of suspensions and porous materials, fluorescence/phosphorescence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

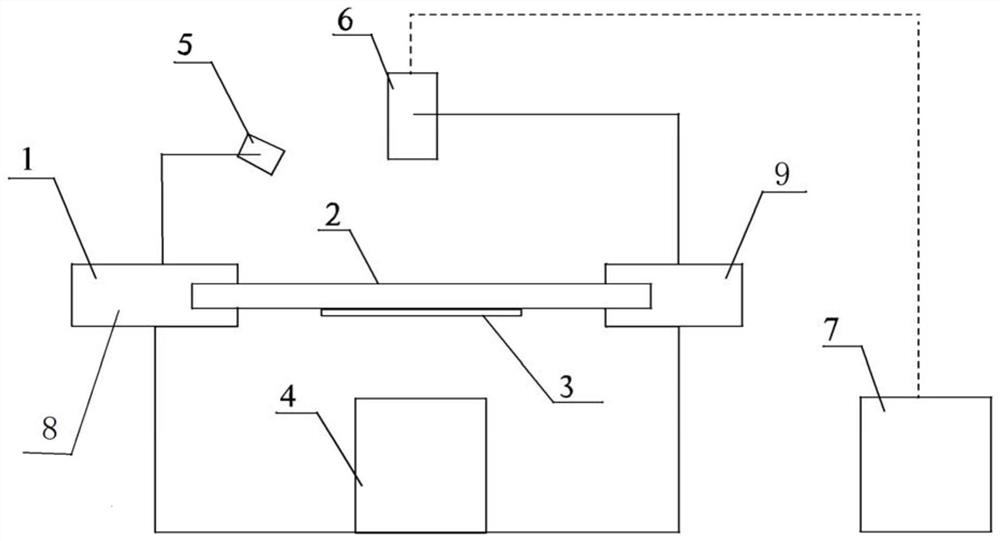

[0061] figure 1 A schematic structural diagram of a rock fracture observation device in an embodiment of the present invention is shown. Such as figure 1 As shown, the embodiment provides a rock fracture observation device, comprising:

[0062] The stage 1, the stage 1 is used to fix the rock sample 2; the magnetic field generator 4, the magnetic field generator 4 is used to apply magnetic force to the rock sample 2; the light source 5, the light source 5 is used to irradiate the rock sample 2 so that The surface of the fluorescent image is formed; the imaging device 6 is used for collecting the fluorescent image.

[0063] The stage 1 fixes the rock sample 2 along the horizontal direction; the magnetic field generator 4 is arranged under the stage 1 for generating magnetic force in the vertical direction; the light source 5 is arranged above the stage 1 for illuminating the rock sample 2 Upper surface: The imaging device 6 is arranged above the stage 1 and is used to collec...

Embodiment 2

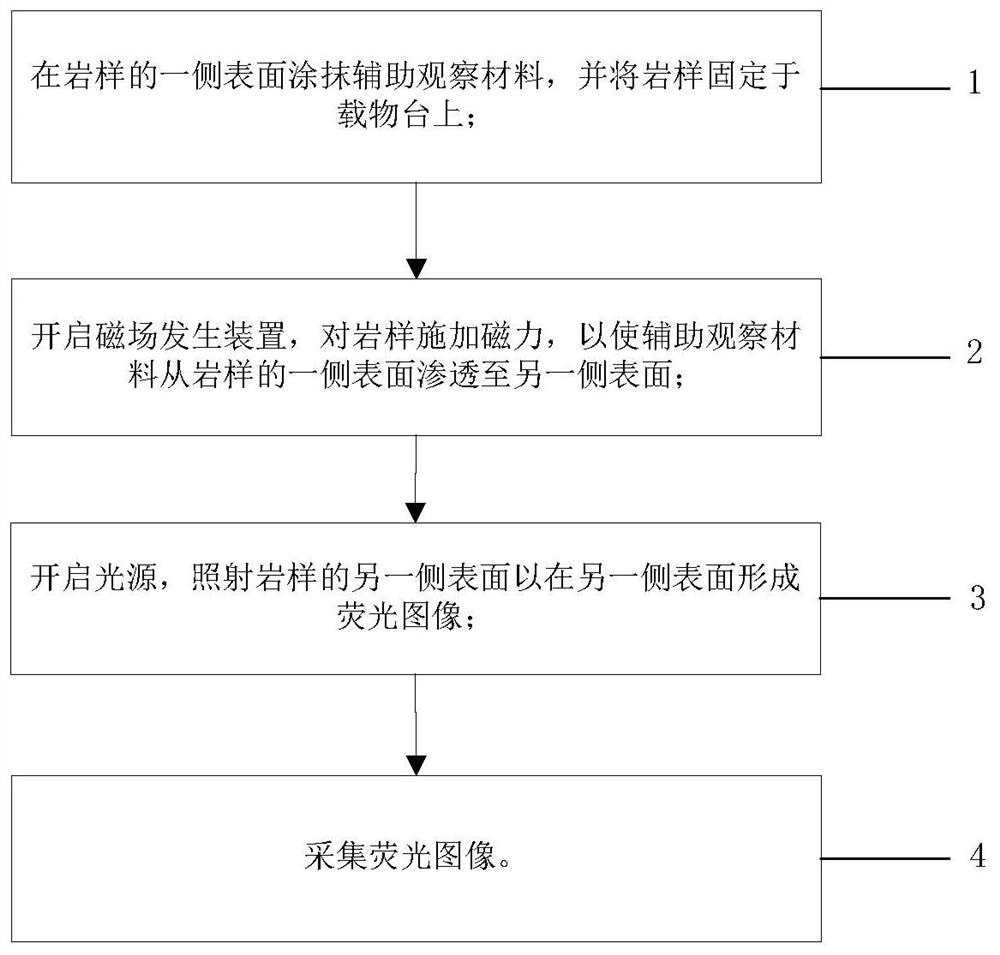

[0066] figure 2 A flow chart of the method for observing rock fractures in one embodiment of the present invention is shown.

[0067] Such as figure 2 As shown, the embodiment provides a rock fracture observation method, the method includes the following steps:

[0068] Step 1: The stage 1 includes a first clamping portion 8 and a second clamping portion 9 which are arranged oppositely, grooves are provided on the inner surface of the first clamping portion 8 and the inner surface of the second clamping portion 9, The groove is used to hold the rock sample 2. The rock sample 2 is processed into sheets, and the thickness of the rock sample 2 is smaller than the height of the groove.

[0069] Step 2: Apply auxiliary observation material 3 on one side of the rock sample 2, and fix the rock sample 2 on the stage 1.

[0070] The stage 1 fixes the rock sample 2 along the horizontal direction, the magnetic field generating device 4 is arranged under the stage 1, the light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com