Molten pool temperature control method in laser cladding forming

A temperature control method and laser cladding technology, applied in coatings, instruments, electrical and digital data processing, etc., can solve the problems of small size, high brightness, difficulty in detection and control of molten pool temperature, and improve accuracy and efficiency. performance, the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

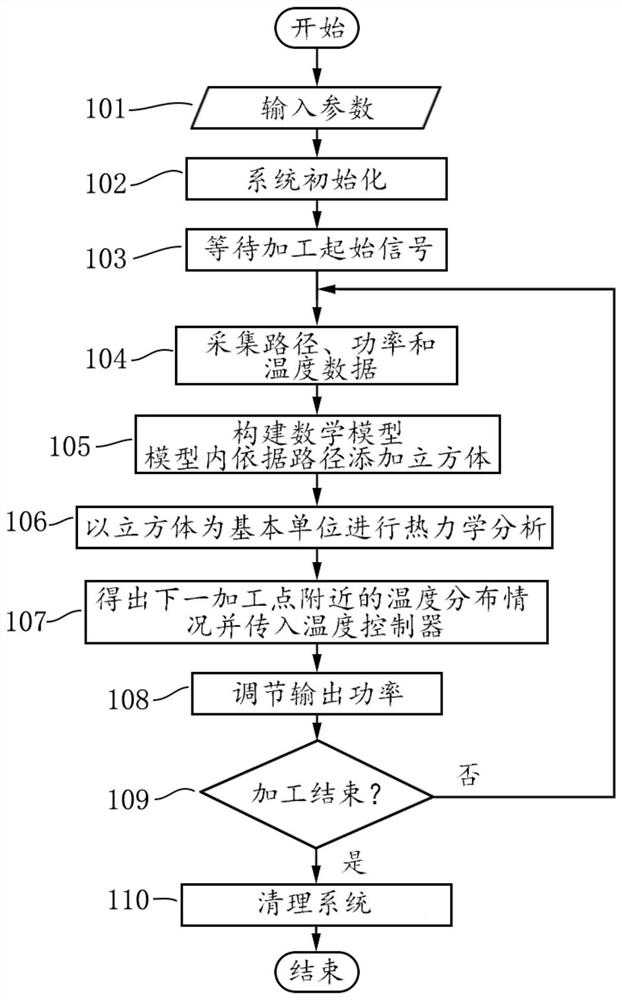

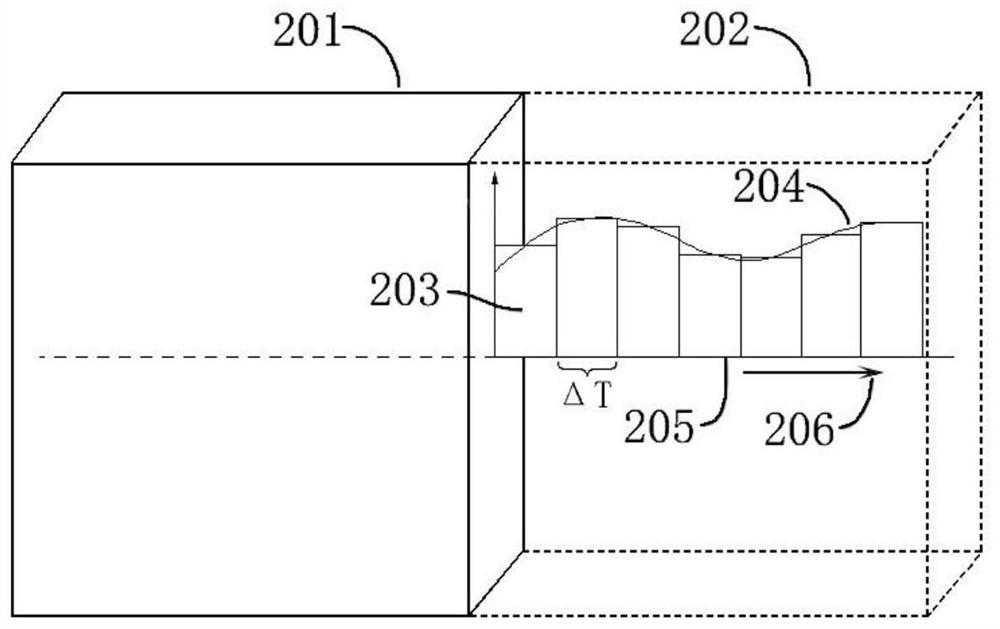

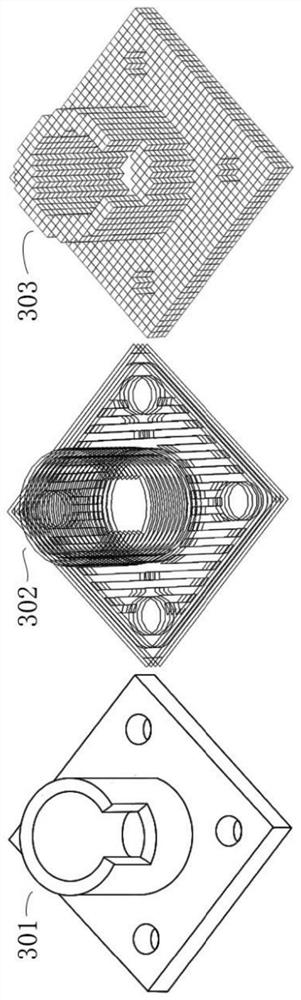

[0029] This example provides a method for controlling the temperature of the molten pool in laser cladding forming, such as figure 1 As shown, this example will start with image 3 Take the square flange with opening as an example to explain the detailed steps:

[0030] Step 101, input the system parameters, set the laser spot shape to be circular, the spot size to be 2mm, the overlap ratio to be 50%, the initial output power of the laser to be 1600W, the laser scanning speed to be 240mm / min, and the metal powder model used to be 316L, The initial ambient temperature is 25°C, the communication baud rate is set to 9600bps, the communication data verification method is cyclic redundancy check, and the laser power output control met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com