Fabrication method of a ridge-type GaAs-based laser with an asymmetric injection window

A laser, asymmetric technology, applied in the structure of the active area, the structure of the optical waveguide semiconductor, etc., can solve the problem of ignoring the control of the divergence angle, to suppress the optical catastrophe damage, reduce the spot pattern, and facilitate the spot shaping or coupling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

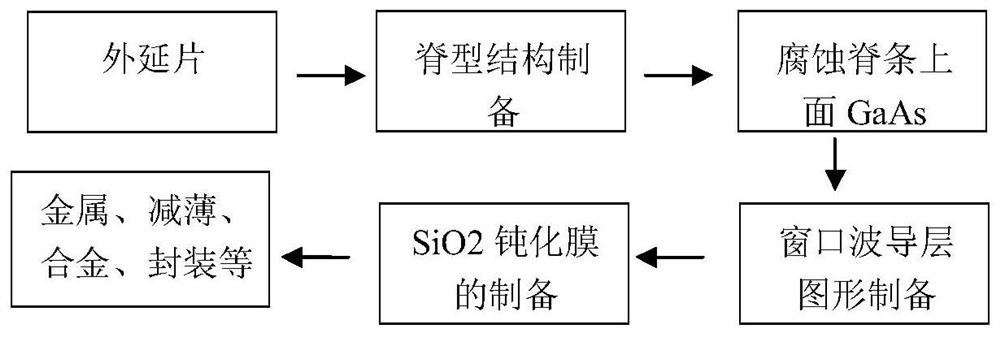

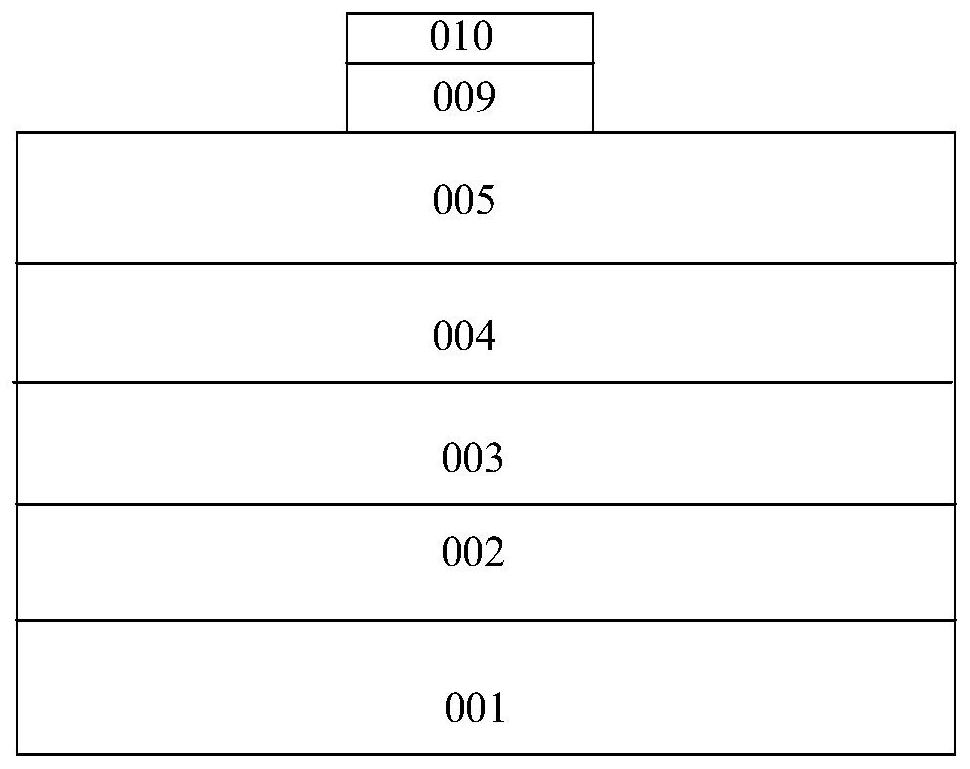

[0031] A preparation method of a ridge-type GaAs-based laser with an asymmetric injection window, the laser includes an epitaxial wafer, and the epitaxial wafer includes a substrate, an N confinement layer, a lower waveguide layer, a quantum well active region, and an upper waveguide that are sequentially arranged from bottom to top layer, P confinement layer and ohmic contact layer, the preparation method is as figure 1 shown, including the following steps:

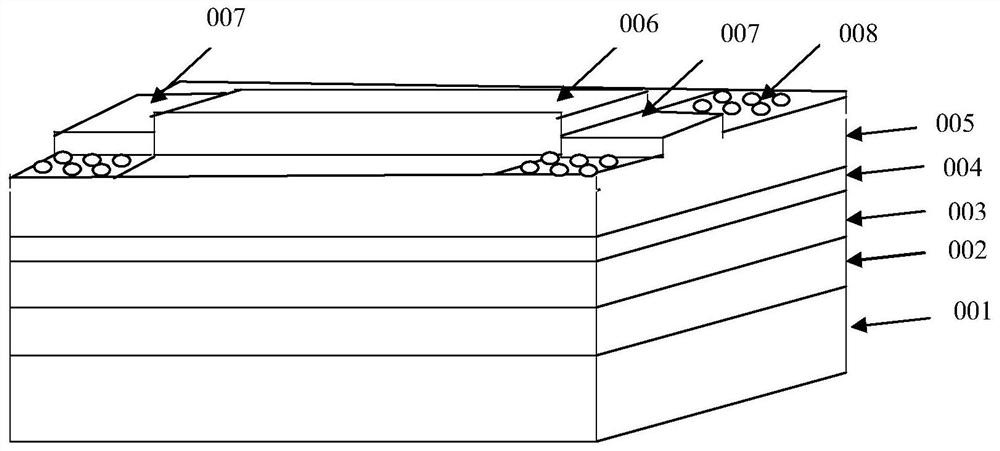

[0032] Step (1), etching a ridge structure on the upper surface of the epitaxial wafer, the ridge structure is located at the center of the epitaxial wafer, and the area other than the ridge structure is etched to the upper waveguide layer, and the ridge structure remains To the ohmic contact layer, the ridge structure runs through the entire cavity length of the epitaxial wafer; as figure 2 shown.

[0033] Step (2), the ridge structure is divided into a ridge light emitting area and a window area, the window area is ...

Embodiment 2

[0040] A preparation method of a ridge-type GaAs-based laser with an asymmetric injection window, the steps of which are as described in Example 1, the difference is that in step (1), the ridge-type structure is located on the side of the epitaxial wafer.

Embodiment 3

[0042] A method for preparing a ridge-type GaAs-based laser with an asymmetric injection window, the steps of which are as described in Example 1, except that in step (3), the prepared figure is elliptical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com