Auxiliary device for automatically cutting long round hole on site

An automatic cutting and auxiliary device technology, applied in auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of unguaranteed construction period and quality, failure to meet quality requirements, high labor and time costs, and save grinding Process and time costs, reduction of operator skill requirements, and the effect of reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

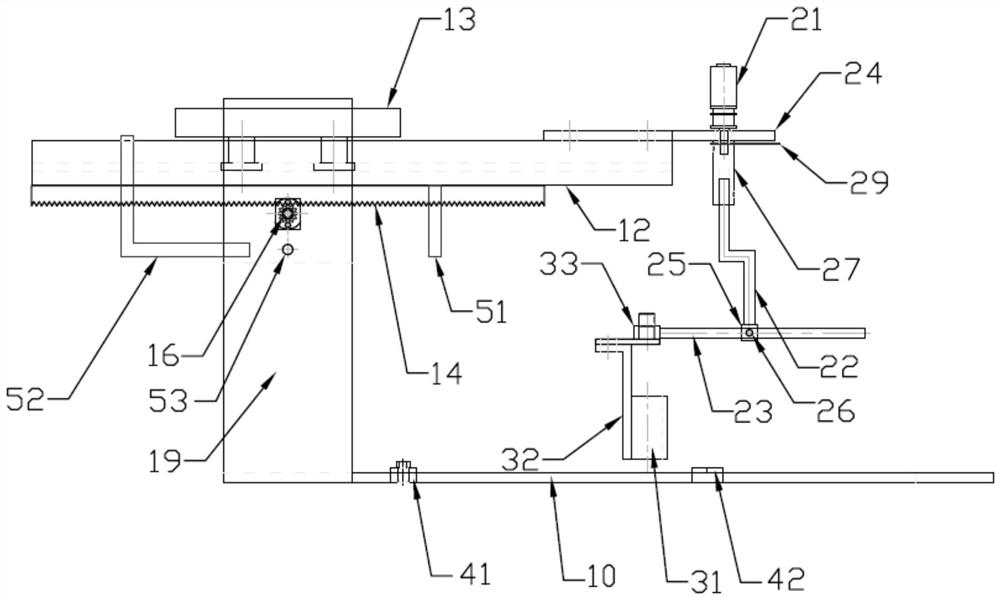

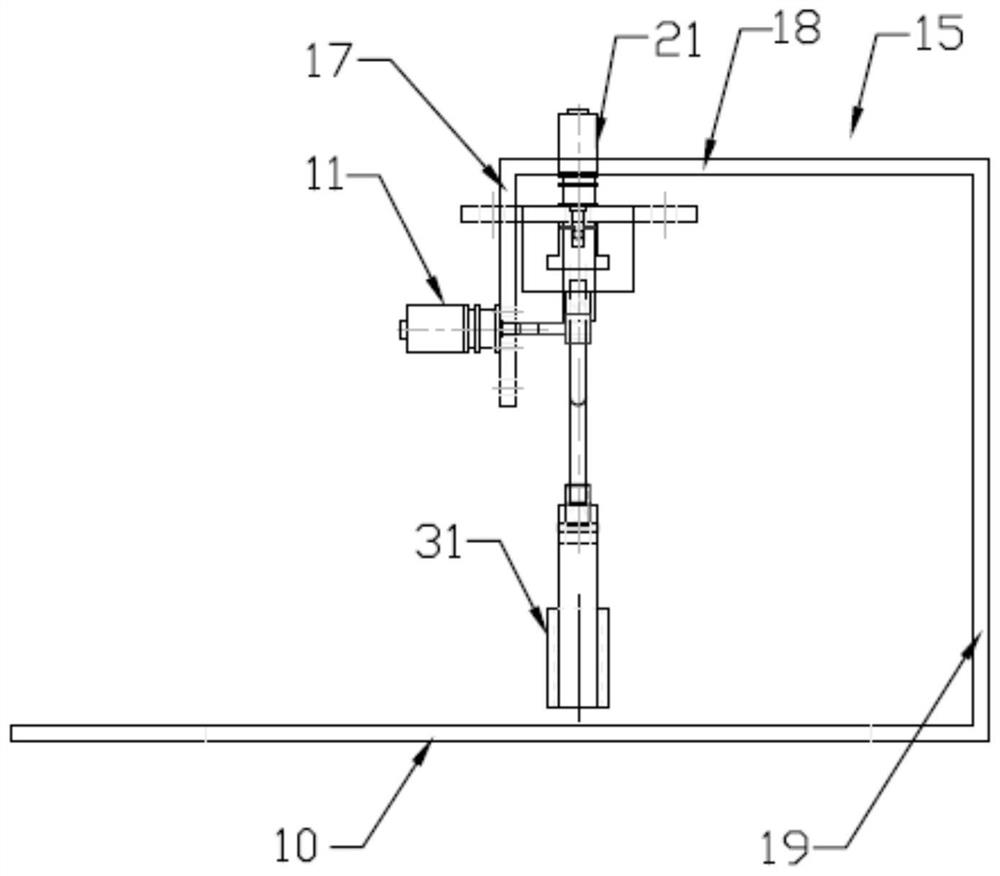

[0022] The on-the-spot strip round hole automatic cutting auxiliary device of embodiment 1, as Figure 1-Figure 3 As shown, it includes a linear drive assembly, an arc drive assembly, a cutting nozzle installation assembly for clamping the cutting nozzle (not shown in the figure), an electrical control box (not shown in the figure), an arc drive assembly and a linear drive The components are connected, the linear drive component is used to drive the arc drive component for linear motion, the cutting nozzle installation component is connected with the arc drive component, and the arc drive component is used to drive the cutting nozzle installation component with the cutting nozzle for circular arc movement, The operation of the linear drive assembly and the arc drive assembly is controlled by the electrical control box.

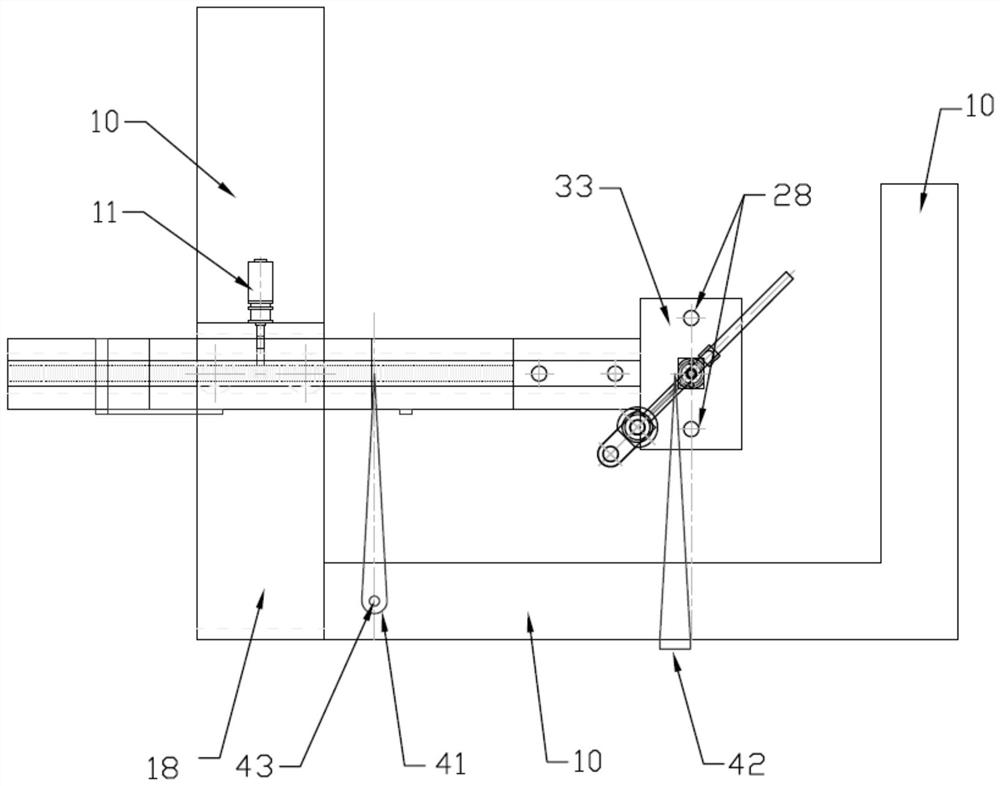

[0023]In Embodiment 1, the linear drive assembly includes a first motor 11, a guide rail 12, a slider 13, a rack 14 and a bracket 15, the rack 14 is fixed on ...

Embodiment 2

[0026] The difference between the on-site automatic cutting auxiliary device for long strips and round holes in embodiment 2 is that in embodiment 2, a zero-position baffle 51 and a moving baffle 52 are arranged on the guide rail 12, and the zero-position baffle 51 is upright and fixed On the front side of the guide rail 12, the movable baffle plate 52 is magnetically adsorbed on the front side of the guide rail 12, the front side of the guide rail 12 is provided with a linear segment cutting length scale line (not shown in the figure), and the rear side plate 17 is equipped with The length control sensor 53 that the mobile baffle 52 is adapted, the length control sensor 53 is electrically connected with the electric control box, and the mobile baffle 52 and the zero position baffle 51 are used to adjust the length of the elongated circular hole to be cut on the workpiece to be processed. Straight line section cutting length; two positioning sensors 28 are installed front and r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap