Manufacturing technology for plastic label imitating metal texture

A production process and metal-imitation technology, which is applied in the field of signage preparation, can solve the problems of easy falling off of the imitation metal texture film, poor metal light and metal feel, and achieve the improvement of the imitation metal texture film, metal light and metal feel. Improve and meet the effect of market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

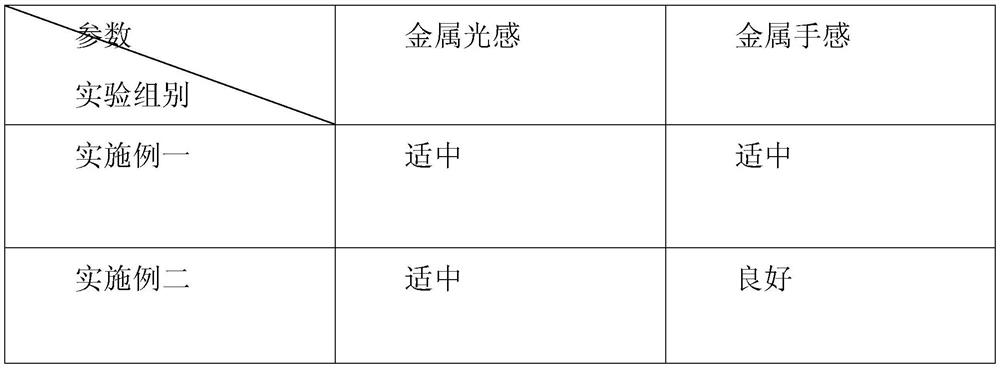

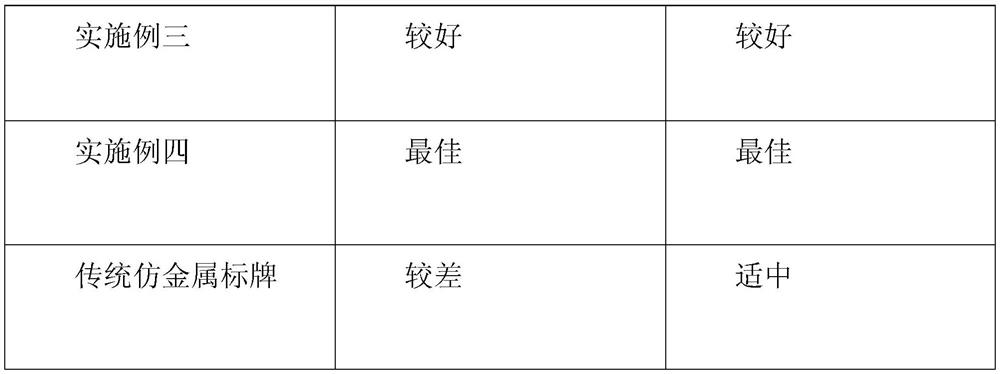

Embodiment 1

[0028] The invention provides a technical solution: a metal-imitating plastic sign making process, the preparation method comprising the following steps:

[0029] S1: Model drawing, select a transparent substrate, and use a laser marking machine to draw the shape of the sign on the surface of the transparent substrate;

[0030] S2: Coil slitting, cutting the transparent substrate by laser along the graphics drawn on the surface of the transparent substrate;

[0031] S3: PET film, cutting the imitation metal texture film, the imitation metal texture film is one circle larger than the size of the transparent substrate;

[0032] S4: Brush glue, apply adhesive colloid evenly on the surface of the transparent substrate, align and lay the imitation metal texture film along one side edge of the transparent substrate, and slowly press the imitation metal texture film on the surface of the transparent substrate with the help of a rubber scraper during the laying process;

[0033] S5: ...

Embodiment 2

[0045] The invention provides a technical solution: a metal-imitating plastic sign making process, the preparation method comprising the following steps:

[0046] S1: Model drawing, select a transparent substrate, and use a laser marking machine to draw the shape of the sign on the surface of the transparent substrate;

[0047] S2: Coil slitting, cutting the transparent substrate by laser along the graphics drawn on the surface of the transparent substrate;

[0048] S3: PET film, cutting the imitation metal texture film, the imitation metal texture film is one circle larger than the size of the transparent substrate;

[0049] S4: Brush glue, apply adhesive colloid evenly on the surface of the transparent substrate, align and lay the imitation metal texture film along one side edge of the transparent substrate, and slowly press the imitation metal texture film on the surface of the transparent substrate with the help of a rubber scraper during the laying process;

[0050] S5: ...

Embodiment 3

[0061] The invention provides a technical solution: a metal-imitating plastic sign making process, the preparation method comprising the following steps:

[0062] S1: Model drawing, select a transparent substrate, and use a laser marking machine to draw the shape of the sign on the surface of the transparent substrate;

[0063] S2: Coil slitting, cutting the transparent substrate by laser along the graphics drawn on the surface of the transparent substrate;

[0064] S3: PET film, cutting the imitation metal texture film, the imitation metal texture film is one circle larger than the size of the transparent substrate;

[0065] S4: Brush glue, apply adhesive colloid evenly on the surface of the transparent substrate, align and lay the imitation metal texture film along one side edge of the transparent substrate, and slowly press the imitation metal texture film on the surface of the transparent substrate with the help of a rubber scraper during the laying process;

[0066] S5: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com