Self-cleaning sphere for cleaning marine oil pollution

A self-cleaning, oil-stained technology, used in open-air water surface cleaning, seawater treatment, general water supply conservation, etc., can solve problems such as skin erosion and technical personnel threats, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

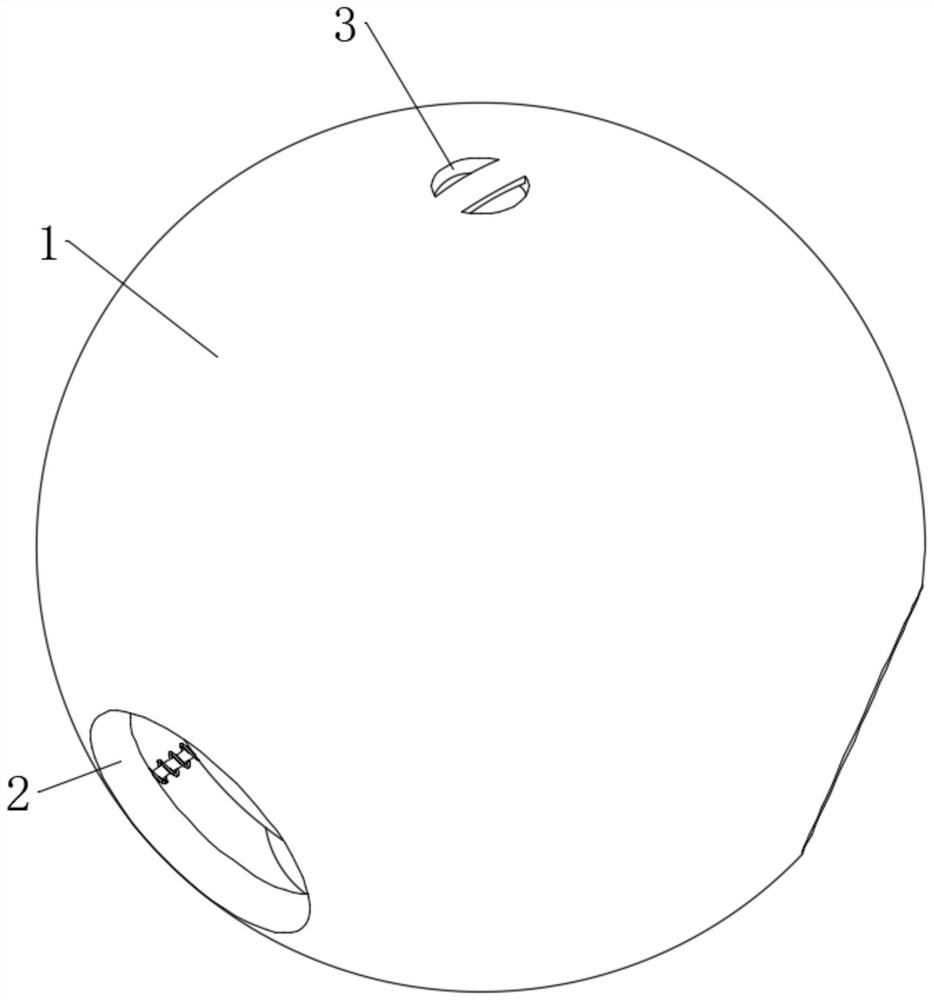

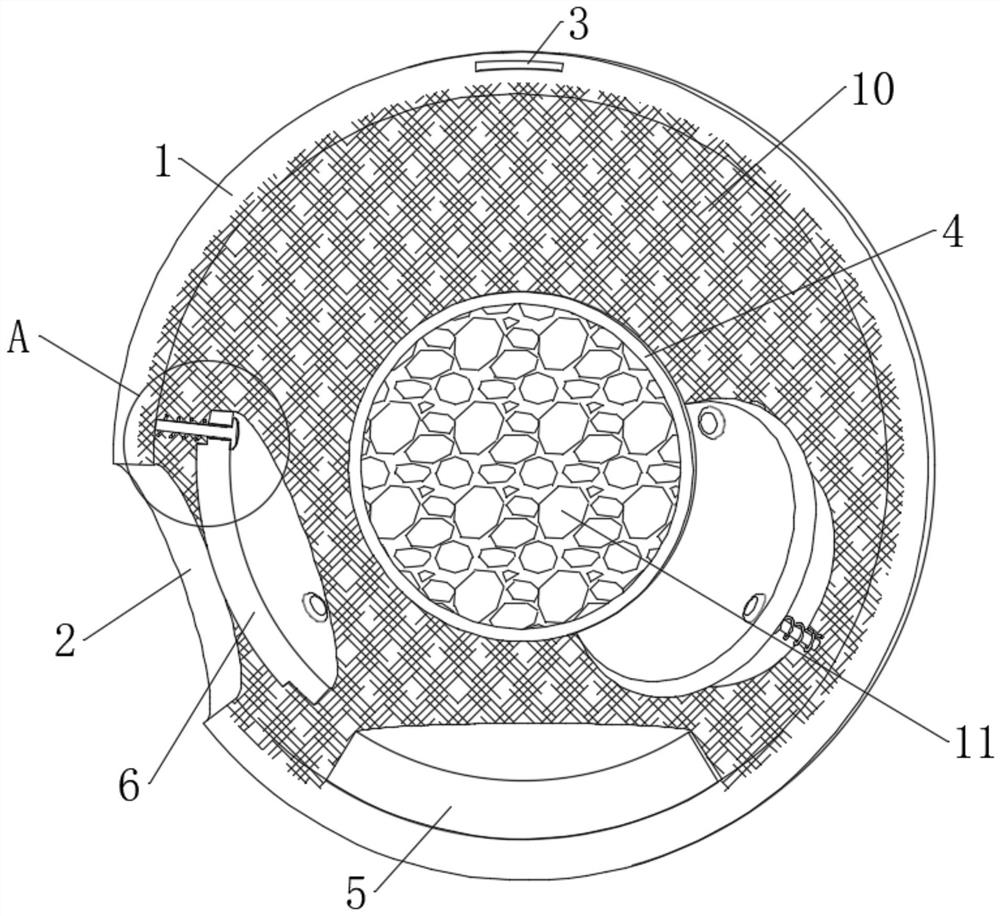

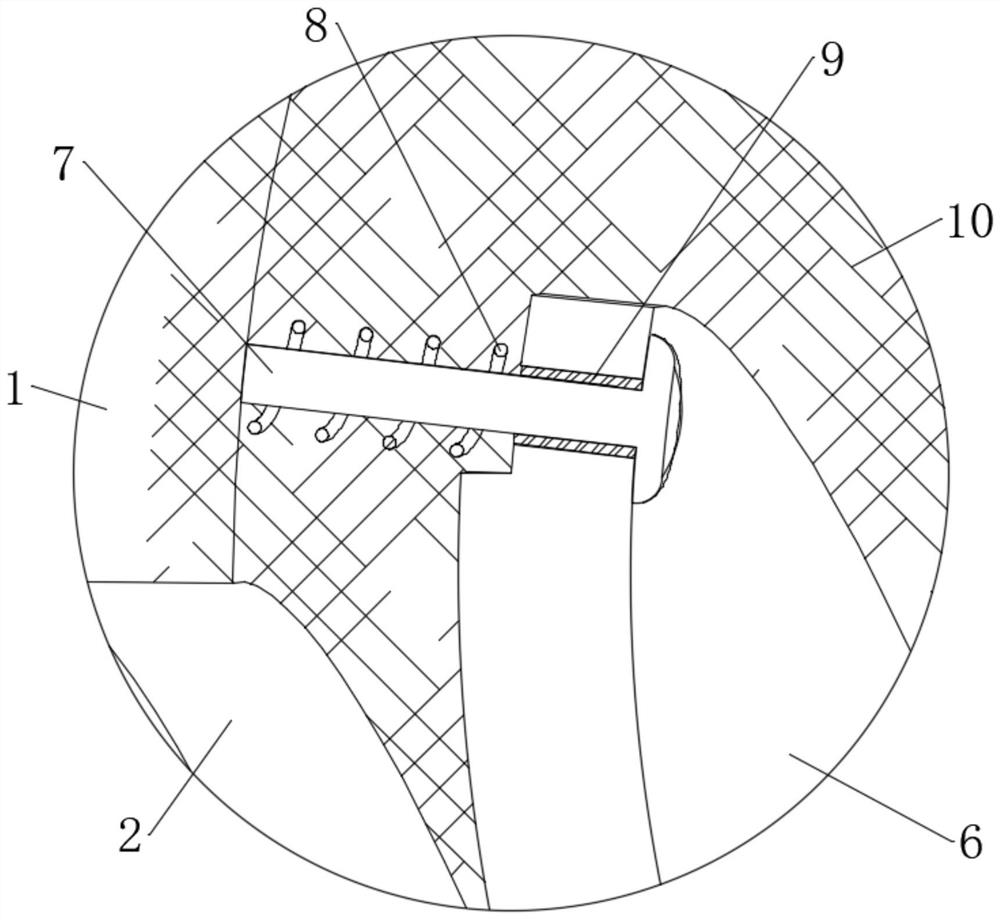

[0033] see Figure 1-3, a self-cleaning ball for cleaning marine oil pollution, including an outer spherical shell 1, three spherical shell through holes 2 are dug on the outer spherical shell 1, and the inner cavity of the outer spherical shell 1 communicates with the outside world through the spherical shell through holes 2 The outer spherical shell 1 is provided with three sealing plates 6 that match the through holes 2 of the spherical shell. The sealing plates 6 are made of elastic materials. The end away from the inner wall of the outer spherical shell 1 is in the shape of a concave platform, so that the sealing plate 6 can be slightly deformed when sliding along the limit nail 7 to adapt to the limit nail 7, and the sealing plate 6 is fixedly connected with the inner wall of the outer spherical shell 1. A plurality of compression springs 8, the outer spherical shell 1 and the sealing plate 6 are connected through the compression springs 8, the outer spherical shell 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com