Drop energy dissipating structure for ultra-deep inspection well

An inspection well and ultra-deep technology, applied in drainage structures, waterway systems, water supply devices, etc., can solve the problems of ultra-deep inspection wells without specially designed maintenance channels, difficulty in maintenance and maintenance, and unfavorable gas circulation in the well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

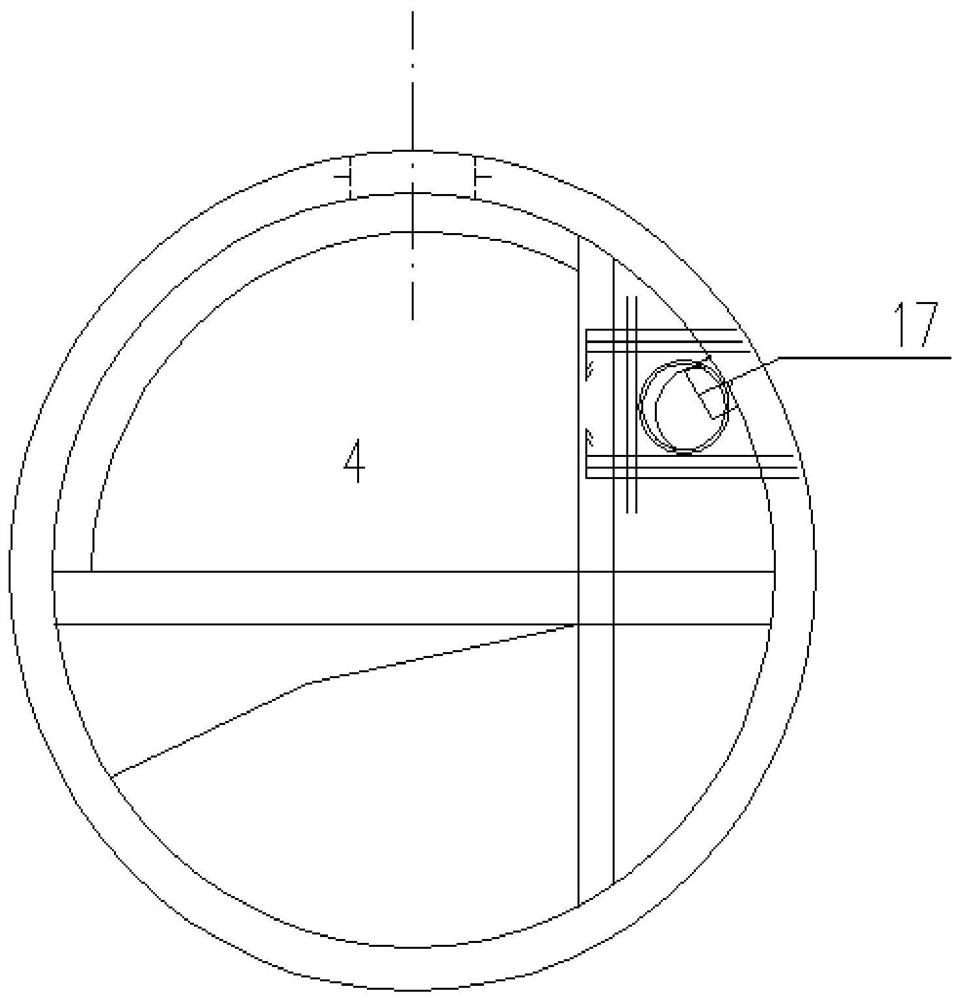

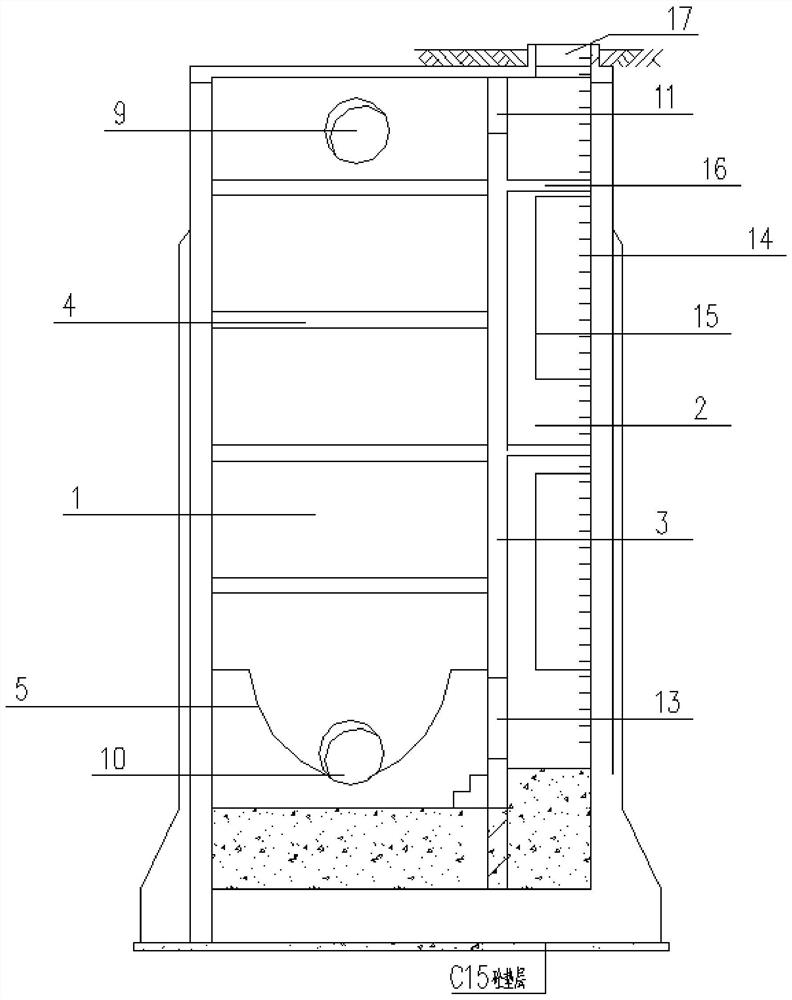

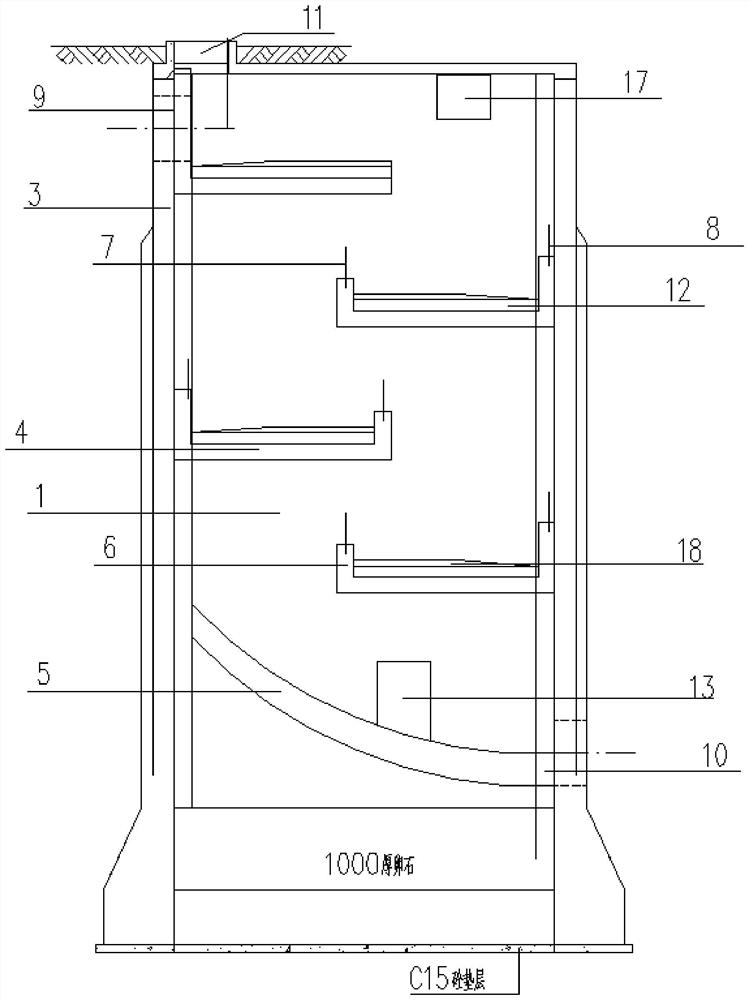

[0040] Such as Figure 1-3 As shown, this embodiment provides a water drop energy dissipation structure applied to ultra-deep inspection wells, including a drainage channel and an inspection channel. On the partition wall, the drainage channel and the maintenance channel are divided into two areas, which is convenient for the staff to do maintenance work on the ultra-deep inspection well;

[0041] A drop plate is arranged in the drainage channel, and a flow channel is arranged under the drop plate at the bottom of the drainage channel, and the flow channel is arranged in an arc shape to introduce sewage into the water outlet pipe;

[0042] The falling boards are arranged staggeredly from top to bottom and on the inside of the left and right walls. Preferably, the vertical distance between the falling boards is 2450mm, and the energy dissipation effect of the selected distance height difference is adopted; The outer side of the drop board is connected to the baffle through the...

Embodiment 2

[0050] Such as image 3 As shown, this embodiment provides a water drop energy dissipation structure applied to ultra-deep inspection wells, including a water drop plate and a baffle connected to the water drop plate, and the water drop plate and the baffle cooperate to realize energy dissipation and reduce noise effect;

[0051] In this embodiment, preferably, the height difference between the first drop board on the upper part and the sewage inlet pipe is less than 1000mm, and due to the small height difference, no baffle is provided on the first drop board; preferably, the surface of a drop board is laid A 200mm thick C20 concrete energy dissipation layer, and a 200mm thick pebble energy dissipation layer laid on the lower dropboard;

[0052] According to the impulse formula F t =△E p ,E p = mv; so F t =△E p =mv-mv 0 =m(v-v 0 ), draw F={m(v-v 0 )} / t;

[0053] In the formula, m is the mass of the object, v is the final velocity, and v 0 is the initial velocity, t ...

Embodiment 3

[0058] Such as image 3 As shown, this embodiment provides a water drop energy dissipation structure applied to ultra-deep inspection wells, including a chute added at the bottom, the chute is arc-shaped, and the energy-dissipated sewage is introduced into the outlet pipe;

[0059] According to the parabolic formula x 2 = 2py, the derived slope k = △Y / △X;

[0060] In this embodiment, the arc-shaped trough belongs to a form of parabola. Preferably, the height of the trough is set to 4000mm and the width is 6800mm; according to the formula k=ΔY / ΔX, ΔY=4000, ΔX= 6800, calculated k=0.588, according to the formula tanA=0.588, A=arctan0.588≈180°XK+30.46°;

[0061] Preferably, the launder is arranged at an oblique angle of 30°, and the angle is an optimal scheme for setting the launder to provide initial power for the sewage to enter the pipeline;

[0062] Preferably, a 100mm thick asphalt board is laid on the launder. The asphalt board has good noise reduction and waterproof effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com