Reinforced concrete belt steel ring plate connecting joint used for precast beam column and connecting method

A technology of reinforced concrete and connection nodes, which is applied in the processing of building materials, building components, and earthquake resistance. The overall construction is convenient, the pouring compactness is improved, and the appearance is beautiful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present embodiment will be described in further detail below in conjunction with the accompanying drawings.

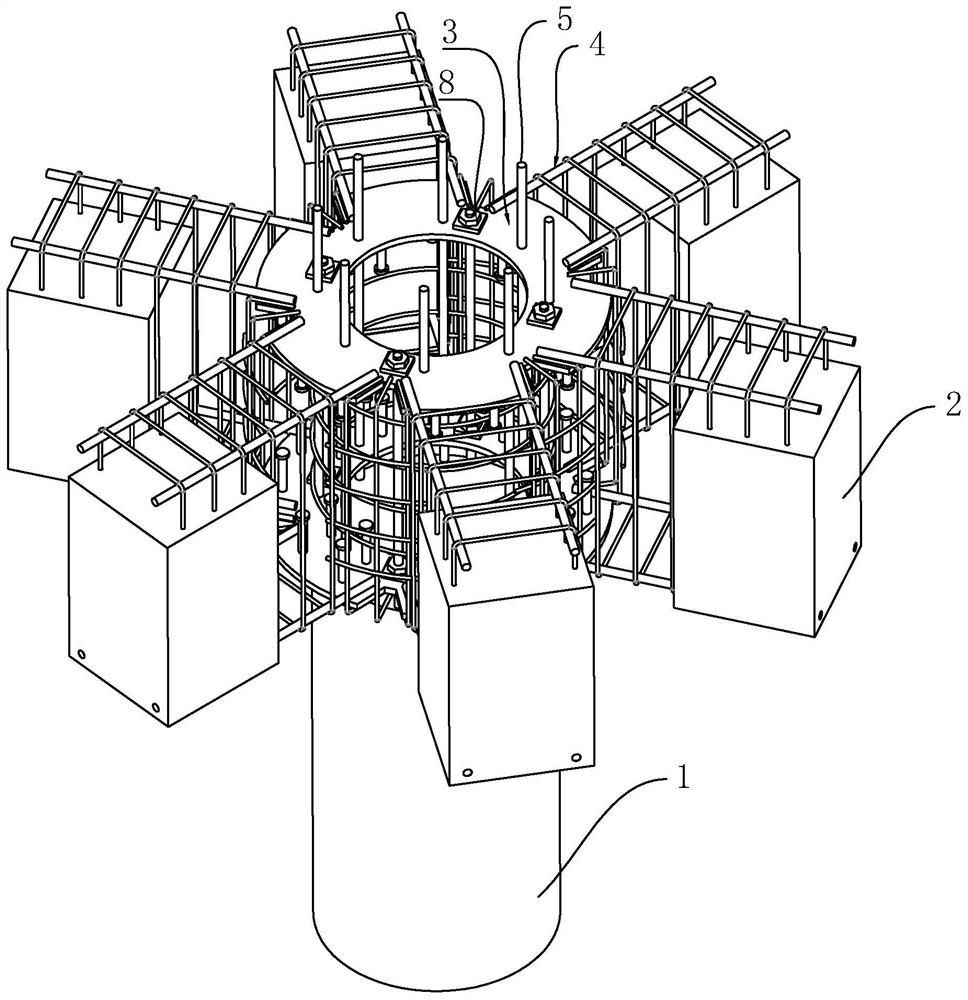

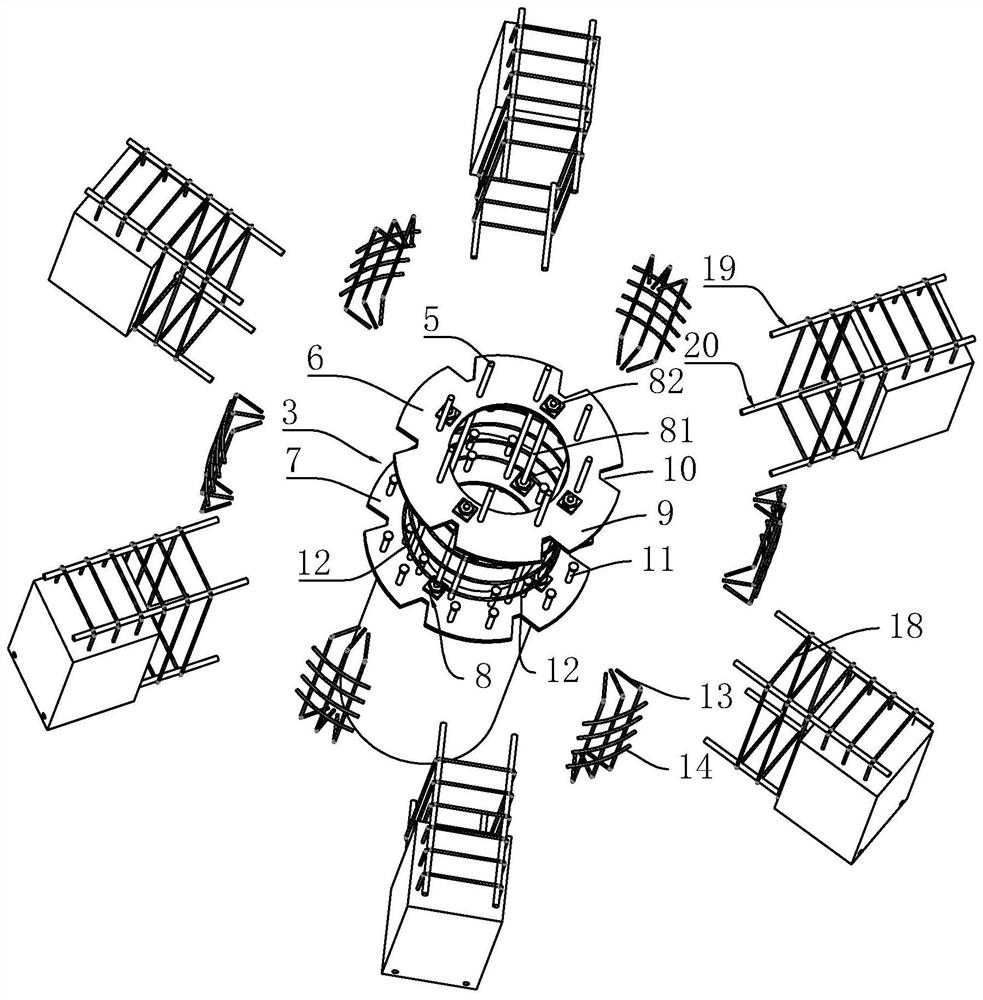

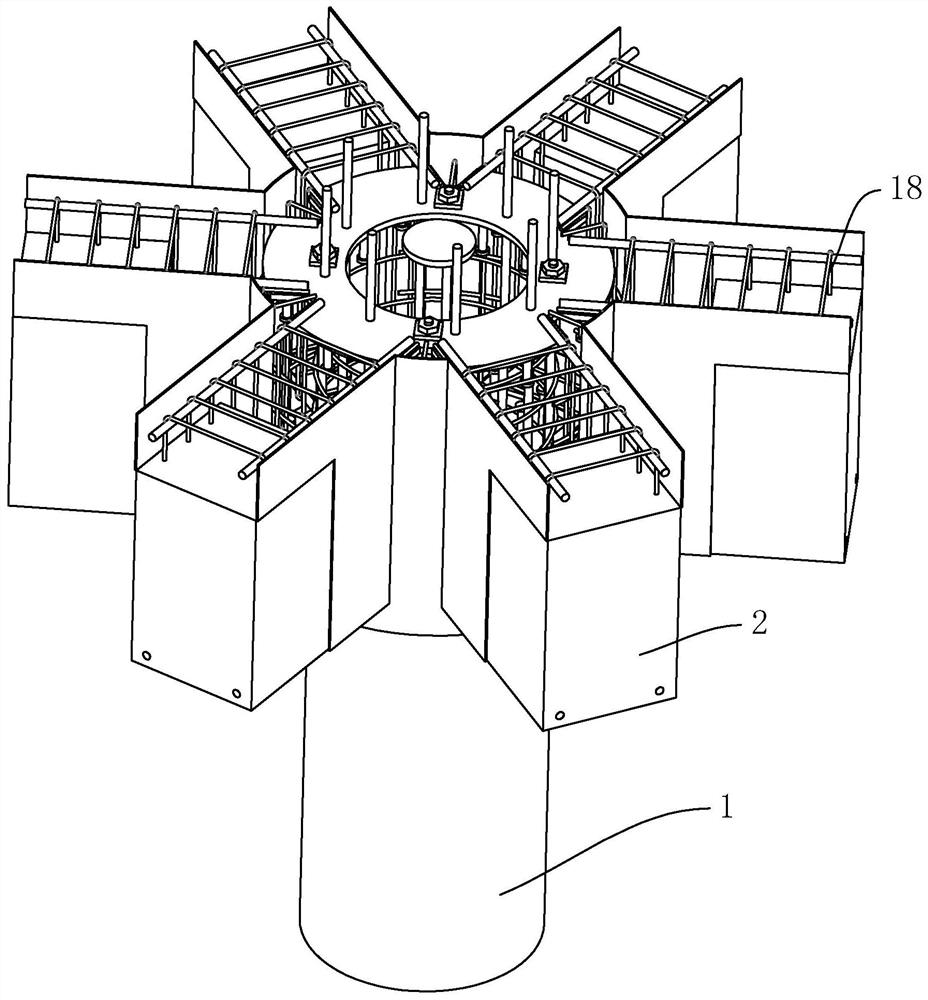

[0056] refer to figure 1 , is a reinforced concrete ring-slab joint with steel ring for prefabricated beams and columns disclosed in this embodiment, which includes a prefabricated column 1 and several prefabricated beams 2 arranged around the prefabricated column 1. In terms of position, several prefabricated beams 2 The center line of the center of the enclosed circle is collinear with the central axis of the prefabricated column 1 . In this embodiment, the prefabricated column 1 and multiple prefabricated beams 2 are mainly connected by reinforcing steel plates 3 and connecting steel bars 4. In addition, a positioning component 8 is provided to help the positioning of the reinforcing steel plates 3, and various steel bars and stirrups are provided to reinforce the joints. connection to enhance shear resistance.

[0057] The specific connection method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com