Boiler control method and system based on automatic optimization fuzzy three-level PID

A boiler control, fuzzy technology, applied in the control field, can solve the problems of poor robust performance and dynamic characteristics, weak system coupling, single control object, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

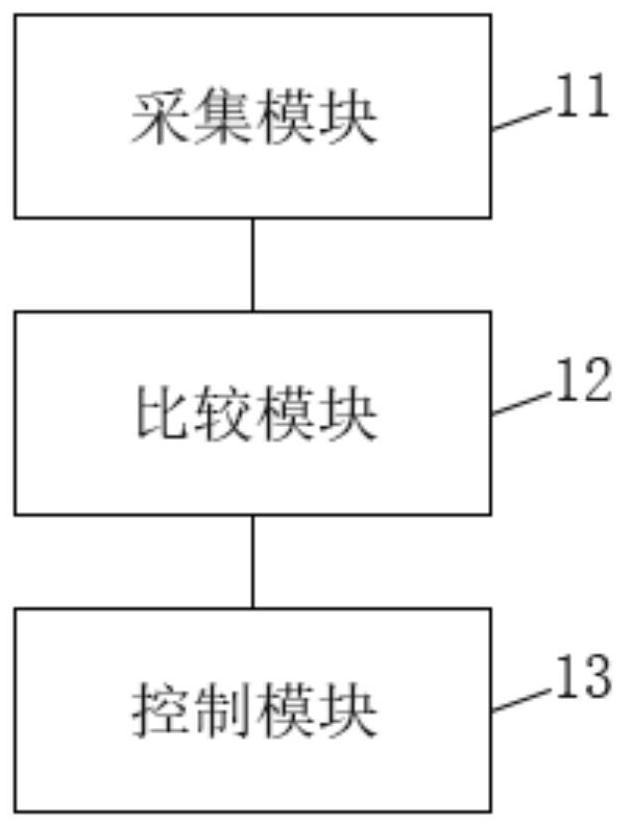

[0041] This embodiment provides a boiler control system based on automatic optimization fuzzy three-level PID, such as figure 1 shown, including:

[0042] The collection module 11 is used to collect the input value of the sensor in the boiler steam; the input value of the sensor includes a steam pressure value;

[0043] The comparison module 12 is connected with the collection module 11, and is used for comparing and processing the collected steam pressure value with the preset target value to obtain a comparison result;

[0044] The control module 13 is connected with the comparison module 12 and is used for executing a control instruction corresponding to the comparison result on the boiler according to the obtained comparison result.

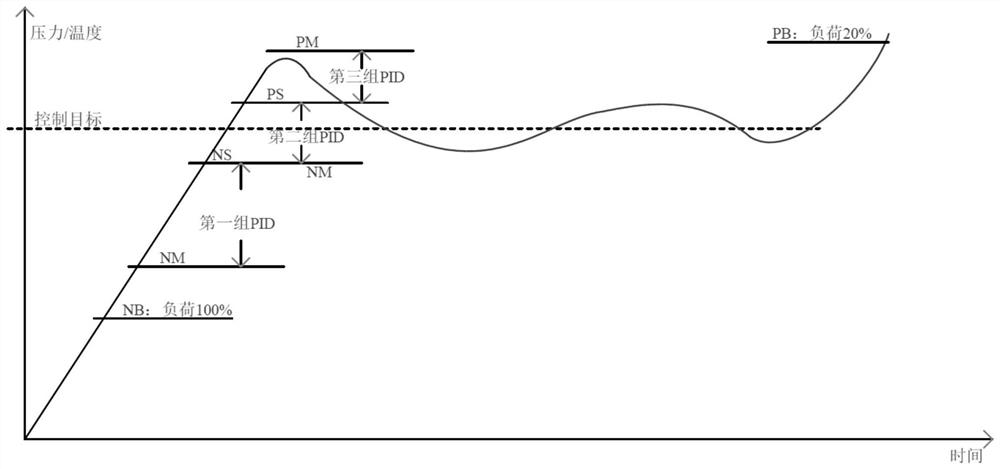

[0045] The automatic optimization fuzzy three-level PID in this embodiment is generated by using fuzzy reasoning, automatic optimization and three sets of PID adjustment algorithms.

[0046] In the collection module 11, it is used to collec...

Embodiment 2

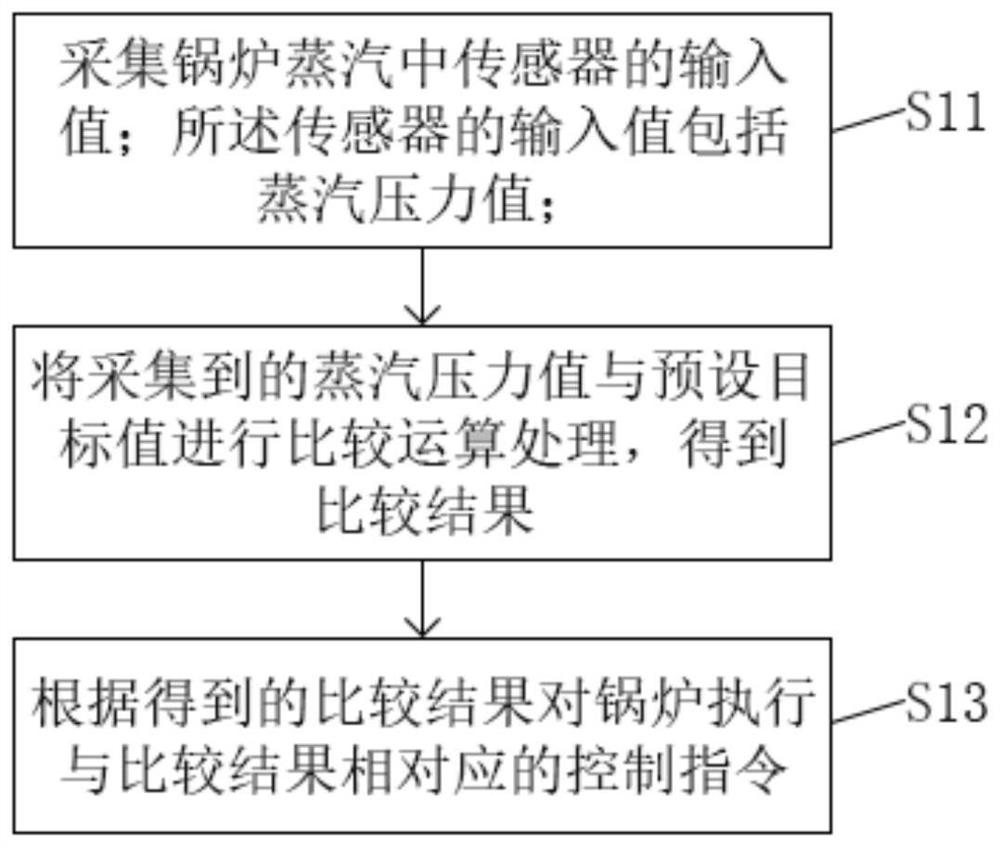

[0092] This embodiment provides a boiler control method based on automatic optimization fuzzy three-level PID, such as image 3 shown, including:

[0093] S11. It is used to collect the input value of the sensor in the boiler steam; the input value of the sensor includes the steam pressure value;

[0094] S12. Comparing and processing the collected steam pressure value with the preset target value to obtain a comparison result;

[0095] S13. Execute a control instruction corresponding to the comparison result to the boiler according to the obtained comparison result.

[0096] Further, the step S12 specifically includes:

[0097] Determine whether the collected steam pressure value is less than the target + NB value;

[0098] Determine whether the collected steam pressure value is greater than the target + NM value and less than the target + NS value;

[0099]Determine whether the collected steam pressure value is greater than or equal to the target + NS value and less than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com