Metasurface-based heterogeneous integrated terahertz front end and manufacturing method thereof

A metasurface and integrated terahertz technology, applied in the terahertz front-end field, can solve the problems of volume, weight and cost deterioration, and achieve the effects of scalability, volume reduction, and mass production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

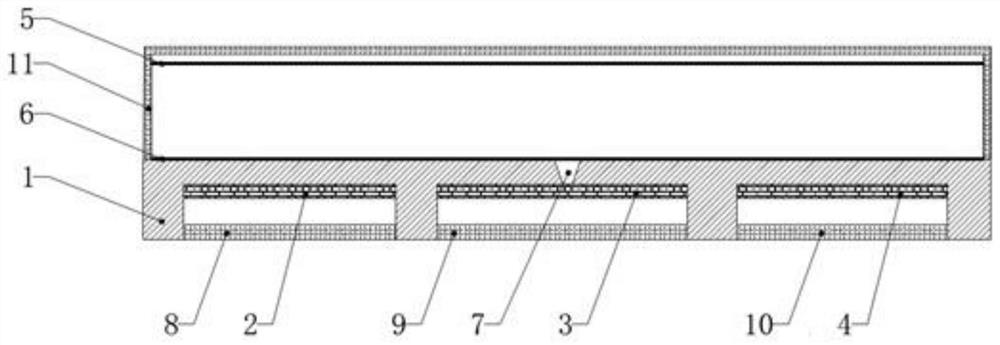

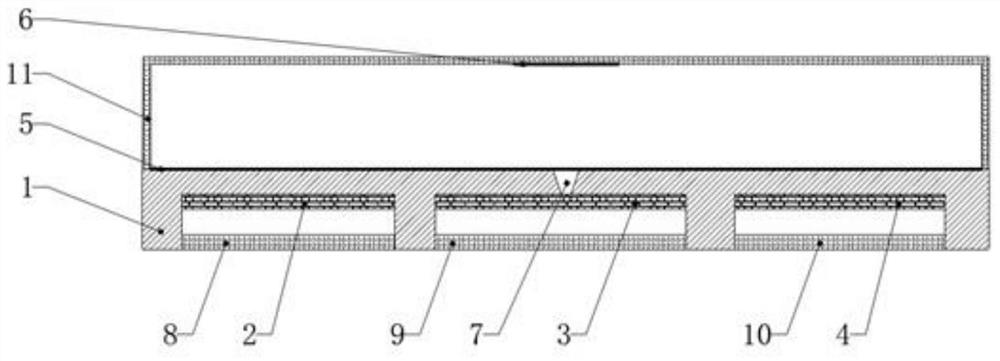

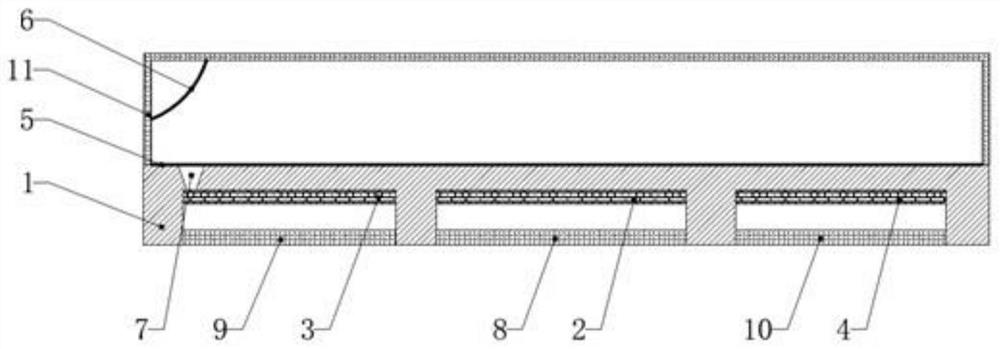

[0042] Such as figure 1 As shown, a metasurface-based heterogeneous integrated terahertz front end of the present invention and its manufacturing method include a housing 1, and the top of the housing 1 is provided with a fourth cover plate 11 with a door structure, and the fourth cover plate 11 forms a cavity with the housing 1, and a metasurface 5 and a reflective surface 6 are arranged in the cavity, and the metasurface 5 adopts an electromagnetic dielectric material, and is covered with a metal film on the insulating dielectric material; the housing 1 is provided with There are a terahertz circuit 3, a power board 2 and a control board 4, the power board 4 is connected with the terahertz circuit 2, the control board 4, and the metasurface 5, and the control board 4 is connected with the terahertz circuit 2, and the metasurface 5, The housing 1 is also provided with a feed source 7 , and the electromagnetic wave generated by the terahertz circuit 2 can radiate to the reflec...

Embodiment 2

[0046] On the basis of Embodiment 1, the bottom of the housing 1 is provided with several installation grooves in sequence along the horizontal direction, and the power board 2, terahertz circuit 3, and control board 4 are respectively located in each installation groove; it also includes a first The cover plate 8, the second cover plate 9 and the third cover plate 10, the first cover plate 8, the second cover plate 9 and the third cover plate 10 can respectively connect the power supply board 2, the terahertz circuit 3, and the control board 4 Packaged in the mounting groove.

[0047] The installed slots are used to respectively install the power board 2, the terahertz circuit 3, and the control board 4, and the first cover plate 8, the second cover plate 9, and the third cover plate 10 are respectively used for packaging in each installation slot. , so that the power board 2, the terahertz circuit 3, and the control board 4 are packaged in their respective installation slots...

Embodiment 3

[0049] On the basis of Example 1, the terahertz circuit 3 includes a terahertz chip and circuit components. The terahertz circuit in this technical solution is a prior art, and the circuit components include amplifiers, mixers, frequency multipliers, Diodes, triodes, capacitors, resistors, and inductors, the specific models of which are not restricted; the power board 2 includes a first printed circuit board, a power chip installed on the first printed circuit board, and a power supply interface, wherein the power chip It is a highly integrated DC-DC switching power supply chip, a linear voltage regulator, a diode, and a triode; the control board 5 includes a second printed circuit board, a control chip installed on the second printed circuit board, and a control interface, Wherein, the control chip is MCU, FPGA, or ARM, DSP.

[0050] The terahertz chip and circuit components of the terahertz circuit 3 are installed in the corresponding area of the terahertz circuit of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com