Method for tendering frozen beef

A technology for frozen beef and tenderization, which is applied in the field of beef processing, can solve the problems of reduced biological enzyme activity, darkened beef color, and poor biological enzyme tenderization effect, and achieves the effect of promoting enzyme tenderization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

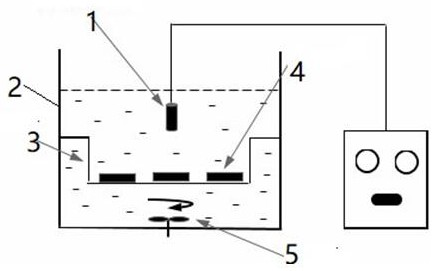

Image

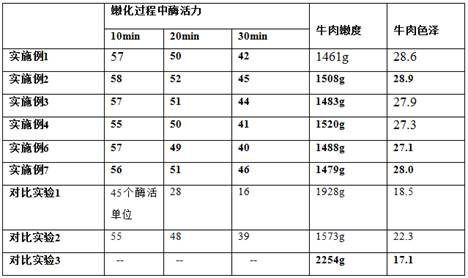

Examples

Embodiment 1

[0032] A method for tenderizing frozen beef, comprising the steps of:

[0033] (1) Beef preparation: divide the frozen beef and set aside;

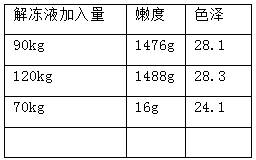

[0034](2) Beef thawing: Put the beef cut in step 1 into a container, inject the thawing liquid, and thaw it under the action of ultrasound, wherein the ultrasound is turned on for 10s and stagnated for 20s as a working cycle, a total of 18 cycles; Ultrasonic working conditions are 24kHZ ~ 40kHZ, among which, the power when thawing is 300 W;

[0035] (3) Osmosis treatment: After the treatment in step (2), add papain hydrolyzate to the container, and then perform osmosis treatment under the action of ultrasonic waves. When the ultrasonic wave is working, the ultrasonic wave is turned on for 10s and stagnated for 20s as a working cycle. Cycle 4 times; the power of penetration is 250W;

[0036] (4) Tenderization treatment: after step (3) infiltration treatment, further tenderization treatment under the action of ultrasound, in which, the ul...

Embodiment 2

[0040] A method for tenderizing frozen beef, comprising the steps of:

[0041] (1) Beef preparation: divide the frozen beef and set aside;

[0042] (2) Beef thawing: Put the beef cut in step 1 into a container, inject thawing liquid, and thaw under the action of ultrasound, wherein the ultrasound is turned on for 10s and stagnant for 20s as a working cycle, a total of 15 cycles; Ultrasonic working conditions are 24kHZ~40kHZ, among which, the power when thawing is 400W;

[0043] (3) Osmosis treatment: After the treatment in step (2), add papain hydrolyzate to the container, and then perform osmosis treatment under the action of ultrasonic waves. When the ultrasonic wave is working, the ultrasonic wave is turned on for 10s and stagnated for 20s as a working cycle. Cycle 3 times; the power of penetration is 300W;

[0044] (4) Tenderization treatment: After the infiltration treatment in step (3), further tenderization treatment under the action of ultrasound, in which, the ultra...

Embodiment 3

[0048] A method for tenderizing frozen beef, comprising the steps of:

[0049] (1) Beef preparation: divide the frozen beef and set aside;

[0050] (2) Beef thawing: Put the beef cut in step 1 into a container, inject thawing liquid, and thaw under the action of ultrasound, wherein the ultrasound is turned on for 10s and stagnant for 20s as a working cycle, a total of 20 cycles; Ultrasonic working condition is 24kHZ~40kHZ, among which, the power when thawing is 350W;

[0051] (3) Osmosis treatment: After the treatment in step (2), add papain hydrolyzate to the container, and then perform osmosis treatment under the action of ultrasonic waves. When the ultrasonic wave is working, the ultrasonic wave is turned on for 10s and stagnated for 20s as a working cycle. Cycle 4 times; the power of penetration is 250W;

[0052] (4) Tenderization treatment: After the infiltration treatment in step (3), further tenderization treatment under the action of ultrasound, in which, the ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com