Valve stent and artificial heart valve including valve stent

A valve and stent sleeve technology, applied in the field of medical devices, can solve the problems of easily damaged sheath, large end recovery resistance, and affecting the valve, so as to reduce the risk of damage to the sheath, reduce loading resistance, and improve the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

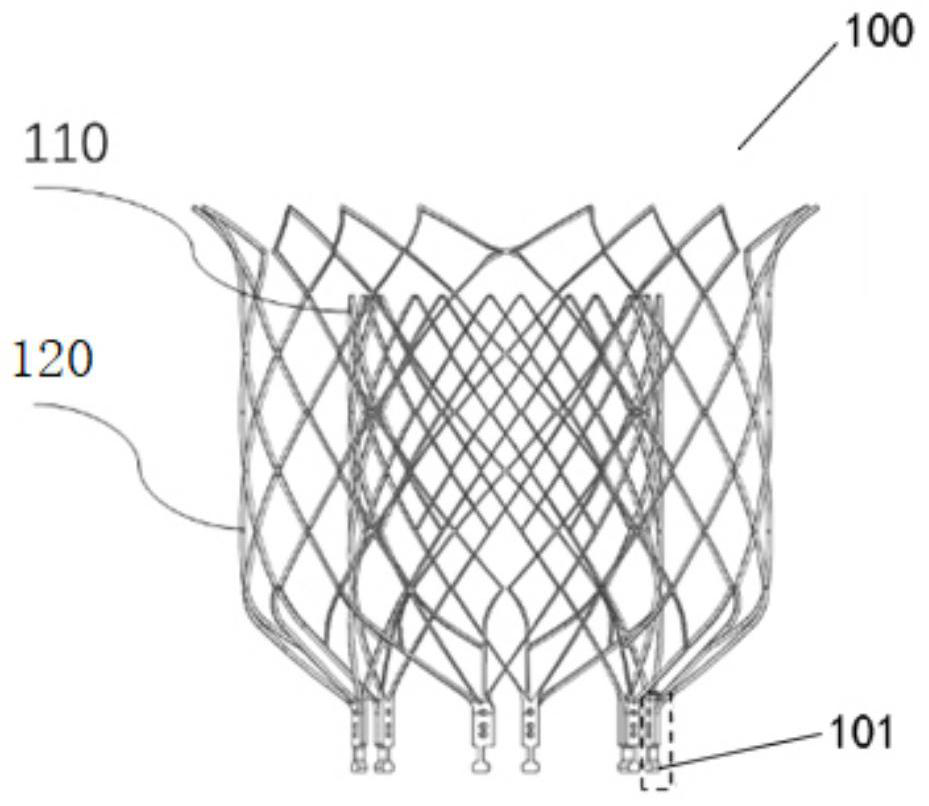

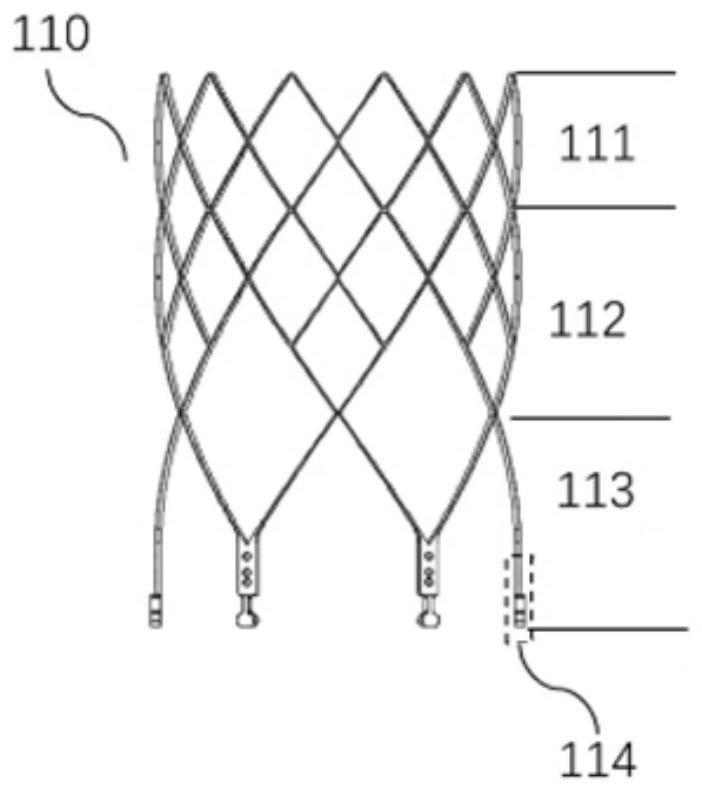

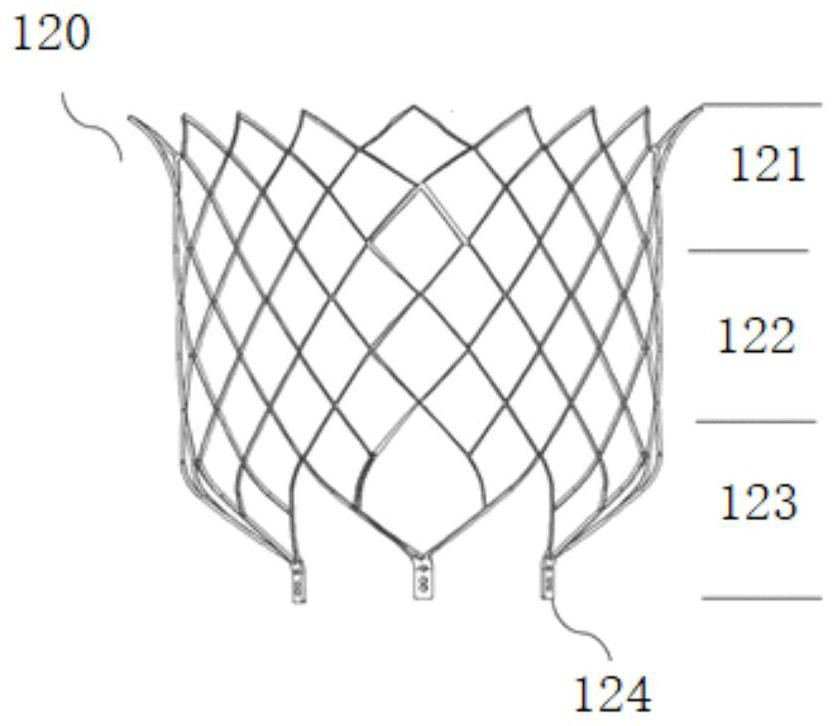

[0064] This embodiment provides a valve stent, including a stent assembly 100, see Figure 1-Figure 8 , wherein, the bracket assembly 100 includes two brackets, an inner bracket 110 and an outer bracket 120, the inner bracket 110 and the outer bracket 120 are nested inside and outside, the inner bracket 110 is sleeved inside, and the outer bracket 120 Set outside.

[0065] The stent assembly 100 is configured to have at least one sheath-in end set 101, and at least one sheath-in end set 101 includes a first sheath-in end 114 and a second sheath-in end 124, wherein the first sheath-in end 114 is located on the inner layer stent 110 , the second sheathing end 124 is located on the outer stent 120 , the first sheathing end 114 and the second sheathing end 124 extend towards the same direction, and the second sheathing end 124 is located outside the first sheathing end 114 .

[0066] In at least one sheath-in end group 101, the length of the first sheath-in end 114 is greater tha...

Embodiment 2

[0080] This embodiment provides a valve support, which is an improvement on the basis of Embodiment 1, wherein the outer contour of the protrusion 200 is arc-shaped.

[0081] Such as Figure 9 As shown, since the first end surface 201 of the protruding part 200 abuts against the end surface 1241 of the second sheathing end, the arc-shaped outer contour can reduce the friction between the end surface of the sheath and the inner wall of the sheath, further Reduced loading resistance.

Embodiment 3

[0083] This embodiment provides a valve stent, which is an improvement on the basis of Embodiment 1 or Embodiment 2, wherein the axial contact surfaces of the first sheath-in end 114 and the second sheath-in end 124 are configured For concave-convex matching connection.

[0084] see Figure 10 , the axial side of the second sheath-in end 124 protrudes outwards with a plurality of second protrusions, and a second recess is formed between two adjacent second protrusions; correspondingly, the axial side of the first sheath-in end 114 forms There are multiple first recesses, and a first protrusion is between two adjacent first recesses 116 . After the inner bracket 110 is connected to the outer bracket 120, the first protrusions are respectively located in a corresponding second recess, and the second protrusions are respectively located in a corresponding first recess, so that the first sheath-in end 114 and the second A concave-convex matching connection is formed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com