Defatted facial mask paper processing technology

A processing technology and mask paper technology, applied in the direction of filter screen, grid, cosmetics, etc., can solve the problems of low efficiency, cannot be crushed while sieving, time-consuming and labor-intensive, etc., to achieve high efficiency, prolong the retention time, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

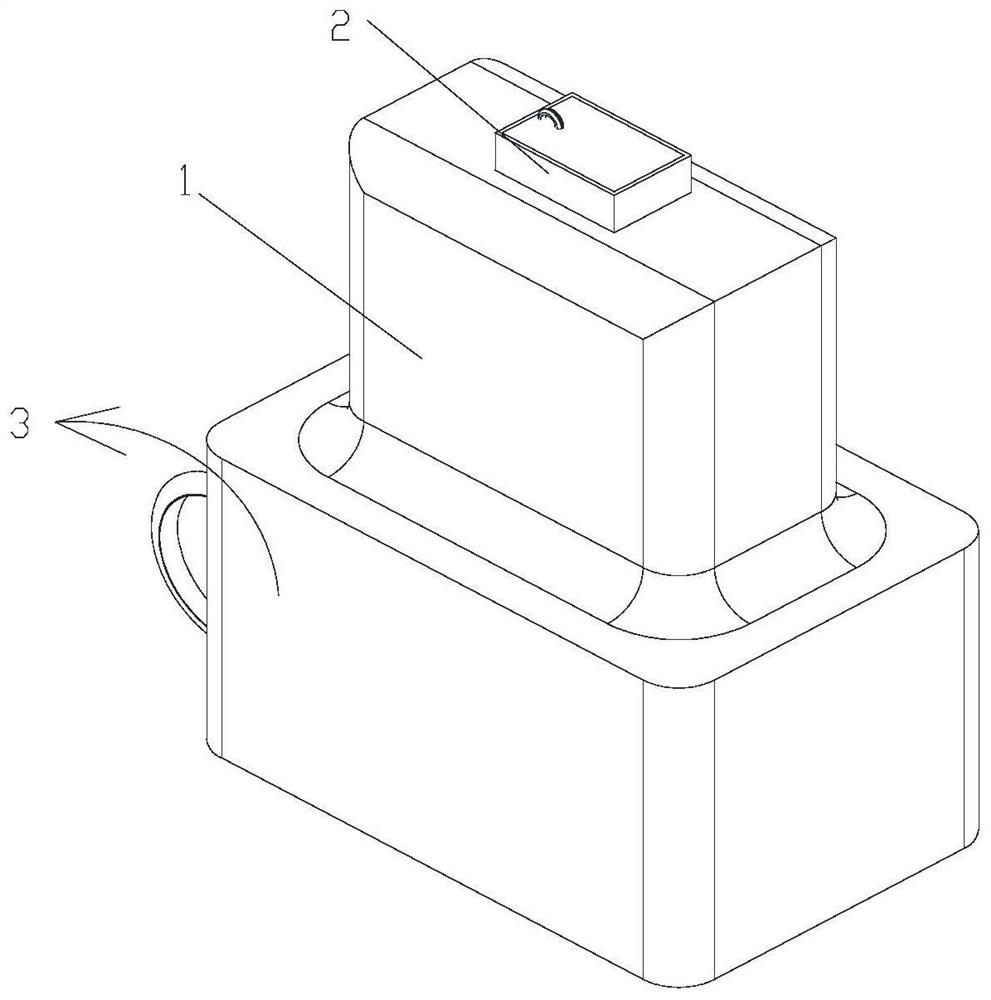

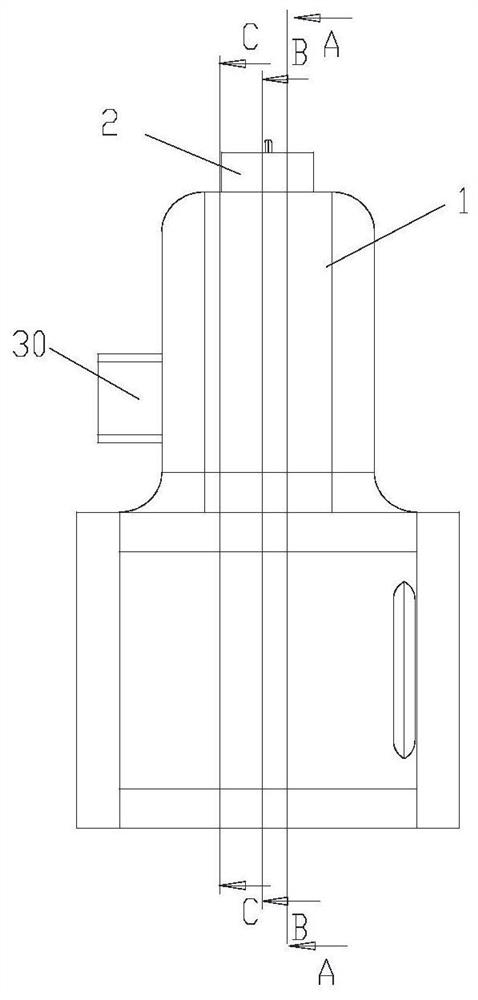

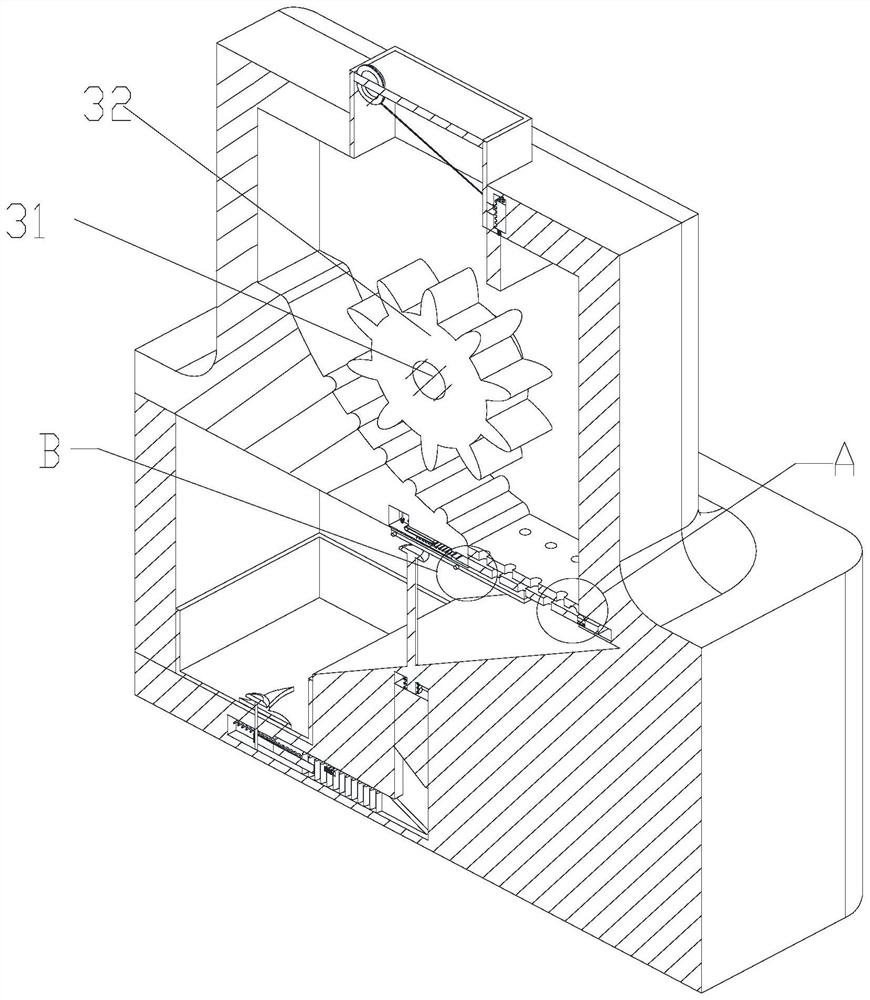

Image

Examples

Embodiment 1

[0046] A processing technology for degreasing facial mask paper, which is mainly made of the following components in proportions by weight:

[0047] Fatty rice bran 5-10%, excipient 4.5-9%, humectant 0.3-3%, and the rest is water.

[0048] The processing technology includes the following steps:

[0049] (1) Take fresh defatted rice bran and put it into a microwave drying oven, heat it at a microwave power of 650w for 90s for stabilization; The particle size should be less than 100 microns; (3) Take agar powder and guar gum and add hot water at 60°C to fully dissolve to obtain a reserve solution; (4) Mix defatted rice bran with corn modified starch; (5) Add the remaining purified water , mix evenly, and carry out homogenization treatment under the pressure of 30-40MPa; (6) The homogenized solution is poured into a mold for molding, dried at a temperature of 90-100°C, and the moisture content is controlled at 75%, and finally the degreased Rice bran mask sheet.

[0050] like ...

Embodiment 2

[0063] A processing technology for degreasing facial mask paper, which is mainly made of the following components in proportions by weight:

[0064] 8 parts of fat rice bran, 7 parts of excipient, 1 part of humectant, and the rest is water.

[0065] The processing technology includes the following steps:

[0066] (1) Take fresh defatted rice bran and put it into a microwave drying oven, heat it at a microwave power of 650w for 90s for stabilization; The particle size should be less than 100 microns; (3) Take agar powder and guar gum and add hot water at 60°C to fully dissolve to obtain a reserve solution; (4) Mix defatted rice bran with corn modified starch; (5) Add the remaining purified water , mixed evenly, and homogenized under 35MPa pressure; (6) The homogenized solution was poured into a mold for molding, dried at a temperature of 95°C, and the moisture content was controlled to 75%, and finally the degreased rice bran mask paper was obtained.

Embodiment 3

[0068] A processing technology for degreasing facial mask paper, which is mainly made of the following components in proportions by weight:

[0069] 10 parts of fat rice bran, 9 parts of excipient, 3 parts of humectant, and the rest is water.

[0070] The processing technology includes the following steps:

[0071] (1) Take fresh defatted rice bran and put it into a microwave drying oven, heat it at a microwave power of 650w for 90s for stabilization; The particle size should be less than 100 microns; (3) Take agar powder and guar gum and add hot water at 60°C to fully dissolve to obtain a reserve solution; (4) Mix defatted rice bran with corn modified starch; (5) Add the remaining purified water , mix evenly, and perform homogenization treatment under 40MPa pressure; (6) Pour the homogenized solution into a mold for molding, dry at 100°C, and control the moisture content to 75%, and finally make defatted rice bran mask paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com