Balance valve control system and control method of asymmetric turbocharger

A turbocharger and control system technology, applied in the direction of charging system, electrical control, engine control, etc., can solve the problems of reducing engine thermal efficiency, energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is described in detail below in conjunction with accompanying drawing:

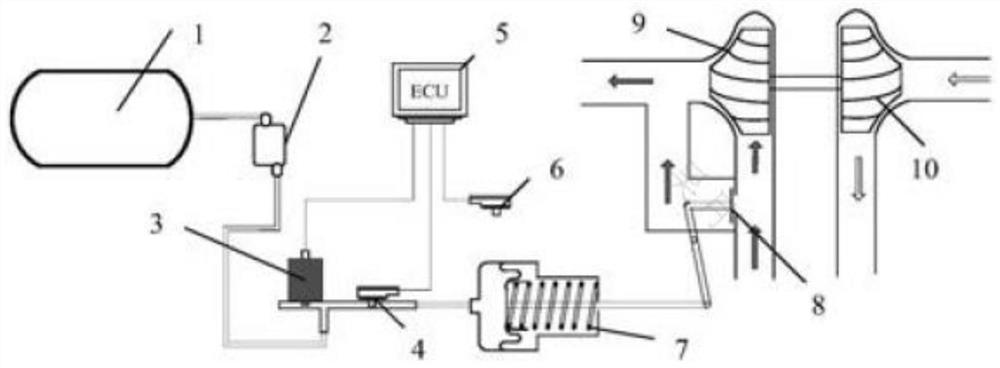

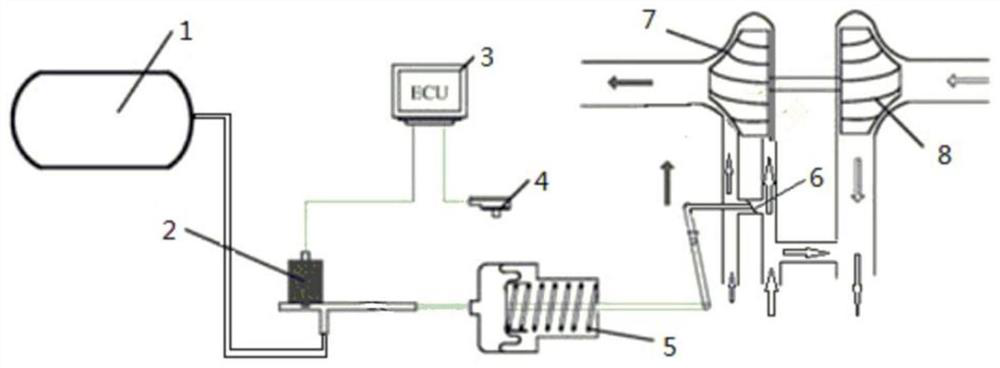

[0056] The invention provides a balance valve control system of an engine asymmetrical turbocharger, such as figure 2 shown. Including compressed air storage tank 1, balance valve control valve 2, engine control unit 3, boost pressure sensor 4, supercharger balance valve control diaphragm valve 5, balance valve valve plate 6, turbocharger turbine 7, booster Air compressor 8.

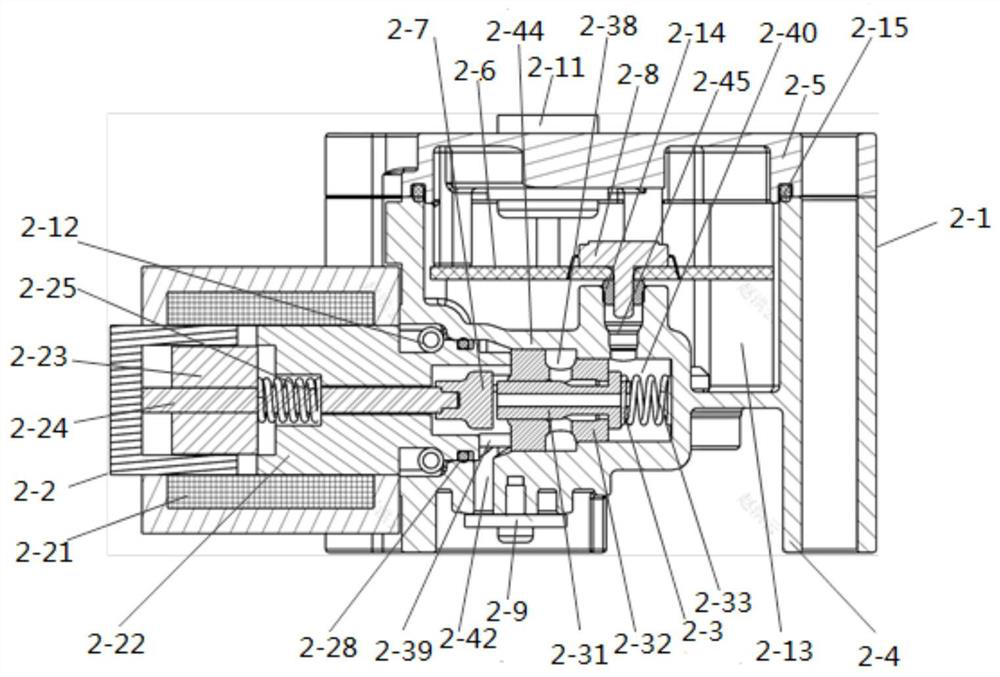

[0057] The compressed air storage tank 1 stores high-pressure gas and is used as a power source; the balance valve control valve 2 is a balance valve control valve with a control valve type, which has the functions of decompression, pressure stabilization and pressure detection, wherein the The left passage of the balance valve control valve 2 communicates with the atmosphere, the right passage is an air outlet, and is connected with the pressure booster balance valve control diaphragm valve 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com