Composite gas cylinder and molding method thereof

A molding method and technology of gas cylinders, which can be applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of asynchronous deformation of the metal bottle head and inner liner layer, large deformation of the inner liner layer, and interface problems. Peeling and other problems to achieve the effect of enhancing adhesion, improving quality, and increasing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Exemplary embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and the descriptions and drawings therein are essentially used for illustration rather than limitation this invention.

[0034] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0035] The invention provides a composite gas cylinder, which can be used for storing and transporting liquefied petroleum gas, natural gas and other high-pressure media.

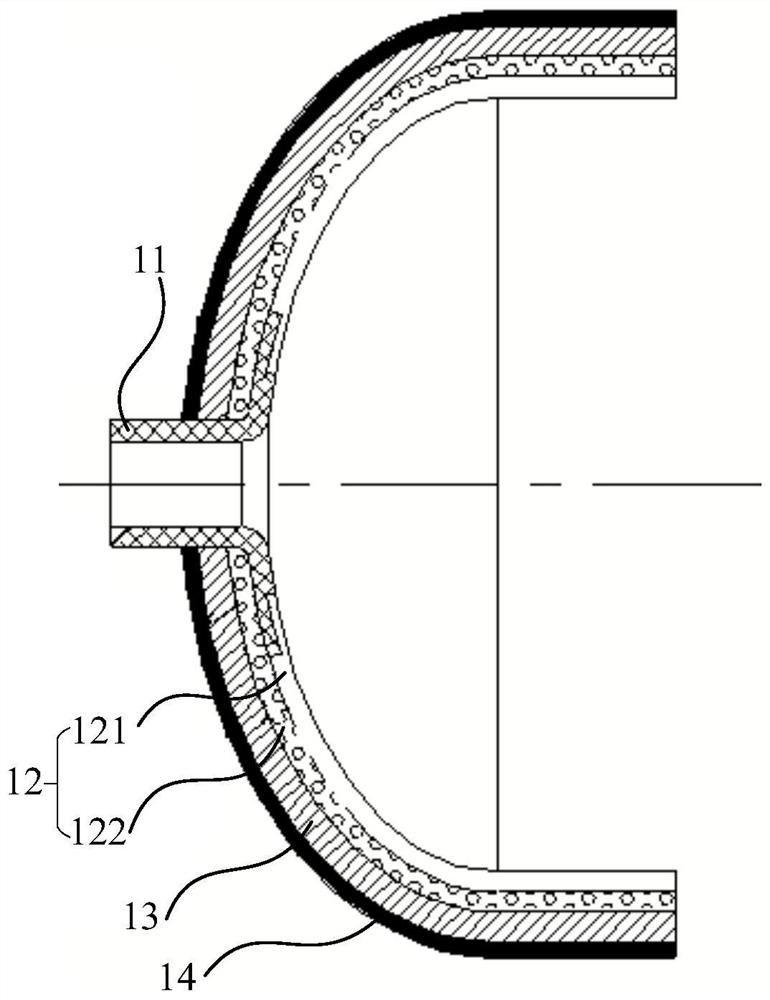

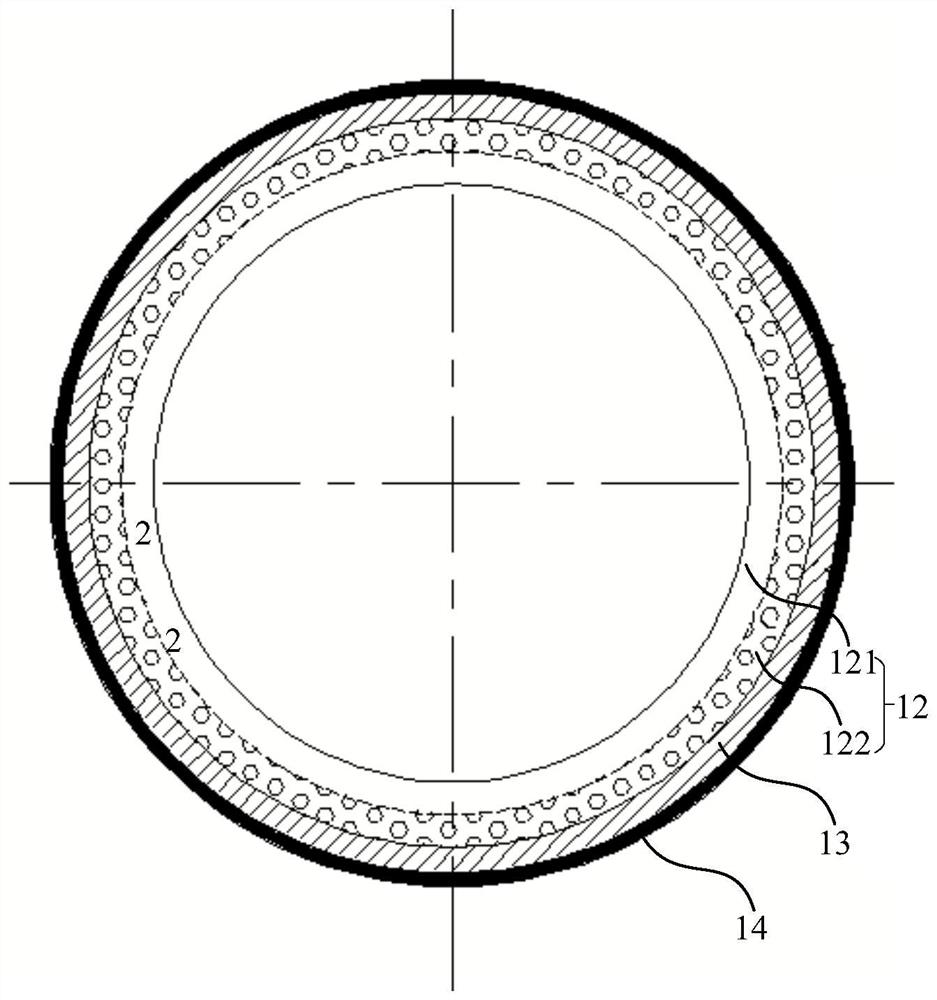

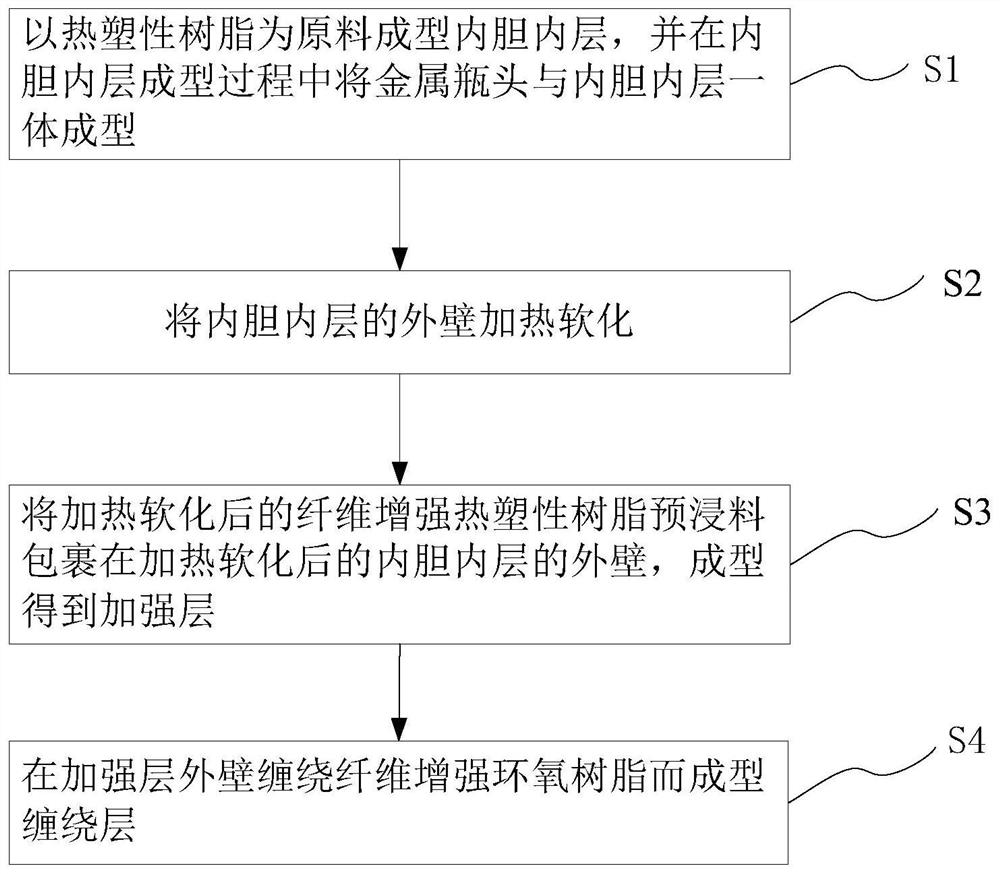

[0036] see figure 1 and figure 2 , the composite gas bottle in this embodiment includes a plastic inner liner 12 , a metal bottle head 11 , a winding layer 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com