Soot blower continuous position monitoring system and method

A monitoring system and a soot blower technology, which are applied in the combustion method, control combustion, safety device of the combustion chamber, etc., can solve problems such as damaged equipment, hidden dangers, and inability to monitor, achieve wide application prospects, simple structure, and reduce discovery long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

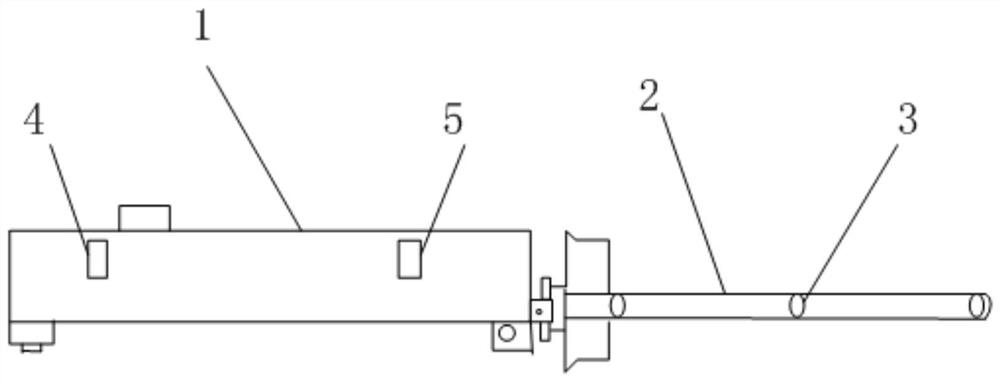

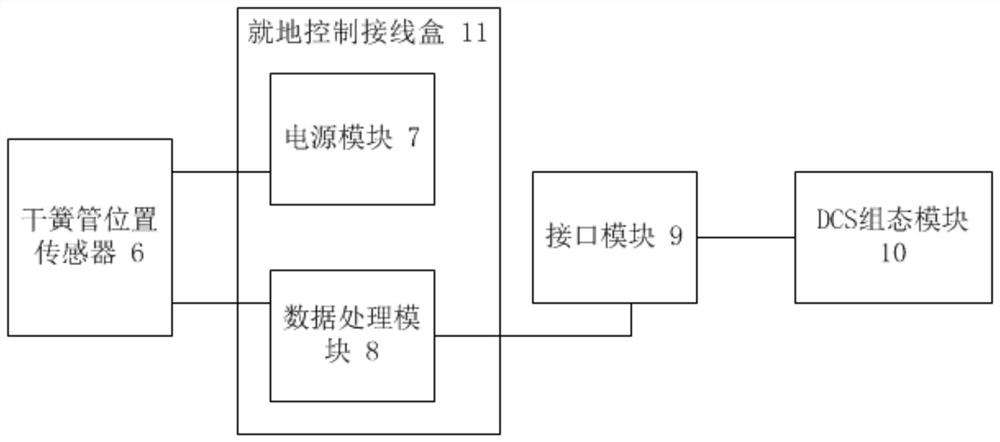

[0088] Such as figure 1 and figure 2 As shown, the present invention provides a continuous position monitoring system for a sootblower, including a reed switch position sensor 6, a local control junction box 11, an interface module 9 and a DCS configuration module 10;

[0089] The sootblower adopts a long telescopic sootblower, including a soot blower and a sports car; the sports car includes a motor and a gear box 1;

[0090] The soot blowing gun includes a nozzle 2, which is provided with a nozzle 3; the nozzle 2 runs through the gear box 1, and the motor drives the nozzle 2 to move forward or backward;

[0091] The gear box 1 is provided with a retractable travel switch 4 and a forward travel switch 5. The retractable travel switch 4 is used to detect whether the print head 2 has reached the maximum backward position, and the forward travel switch 5 is used to detect whether the print head 2 has reached the maximum forward position. Location;

[0092] The reed switch po...

Embodiment 2

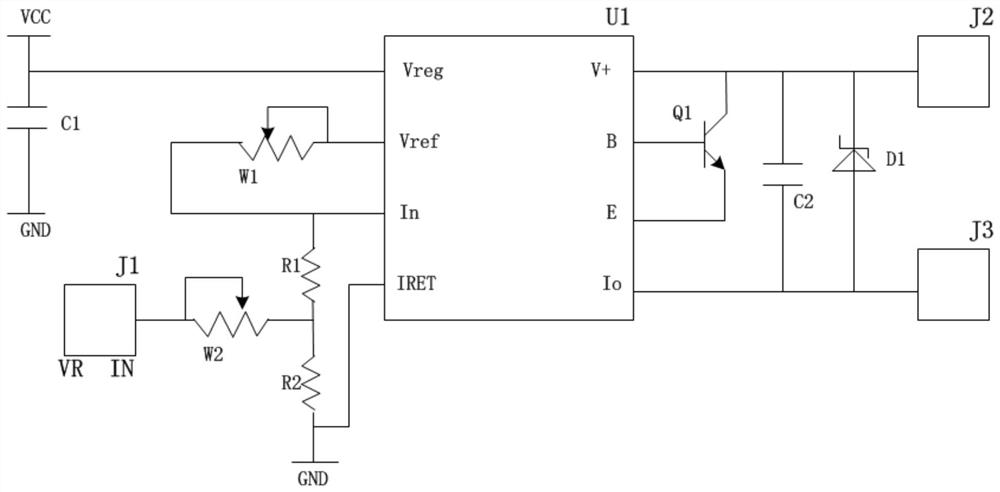

[0104] Such as image 3 As shown, the difference from Embodiment 1 is that the data processing module 8 includes a current loop chip U1, and the current loop chip U1 includes a calibration voltage terminal Vreg, a reference voltage terminal Vref, an input terminal In, a current return terminal IRET, a voltage terminal V+, a base Pole connection terminal B, emitter connection terminal E and current output terminal Io;

[0105] The calibration voltage terminal Vreg is connected to the first capacitor C1 and the power supply terminal VCC, and the other end of the first capacitor C1 is grounded;

[0106] The reference voltage terminal Vreg is connected with a first sliding resistor W1;

[0107] The input terminal In is connected to the first resistor R1, and is also connected to the other end of the sliding resistor W1; the other end of the first resistor R1 is connected to the second resistor R2 and the second sliding resistor W2, and the other end of the second resistor R2 is c...

Embodiment 3

[0116] Such as Figure 4 As shown, in above-mentioned embodiment 1, the quantity of described soot blower is 16, and the quantity of reed switch position sensor 6 and data processing module 8 is equal to the quantity of soot blower, is 16;

[0117] The DCS cards of the interface module 8 are all connected to the sixteen data processing modules, and the sixteen data processing modules 8 are respectively connected to the corresponding reed switch position sensors 6;

[0118] The interface module 9 includes a gating unit 9.1, an analog-to-digital conversion unit 9.2, a photoelectric isolation unit 9.3 and a control unit 9.4;

[0119] The gating unit 9.1 is connected to the analog-to-digital conversion unit 9.2, the analog-to-digital conversion unit 9.2 is connected to the photoelectric isolation unit 9.3, and the photoelectric isolation unit 9.3 is connected to the control unit 9.4;

[0120] The control unit 9.4 is connected with the DCS configuration module 10;

[0121] The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com