A water heater combustion chamber based on high thermal emissivity coating

A radiation coefficient and combustion chamber technology, applied in the direction of burners, combustion types, water heaters, etc., can solve the problems of reducing heat exchange efficiency of heat exchangers, unreasonable design of combustion chamber structure, increasing energy consumption and gas supply, etc. , to achieve the effect of heat energy utilization, safety and environmental protection, avoiding toxic and harmful gases, and improving heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

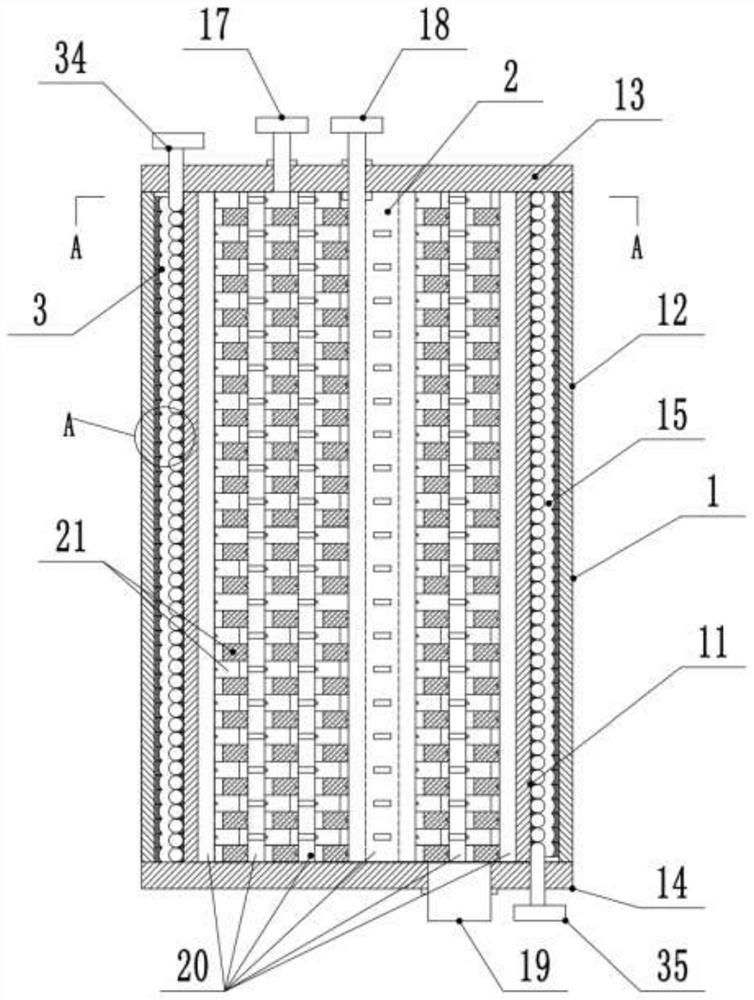

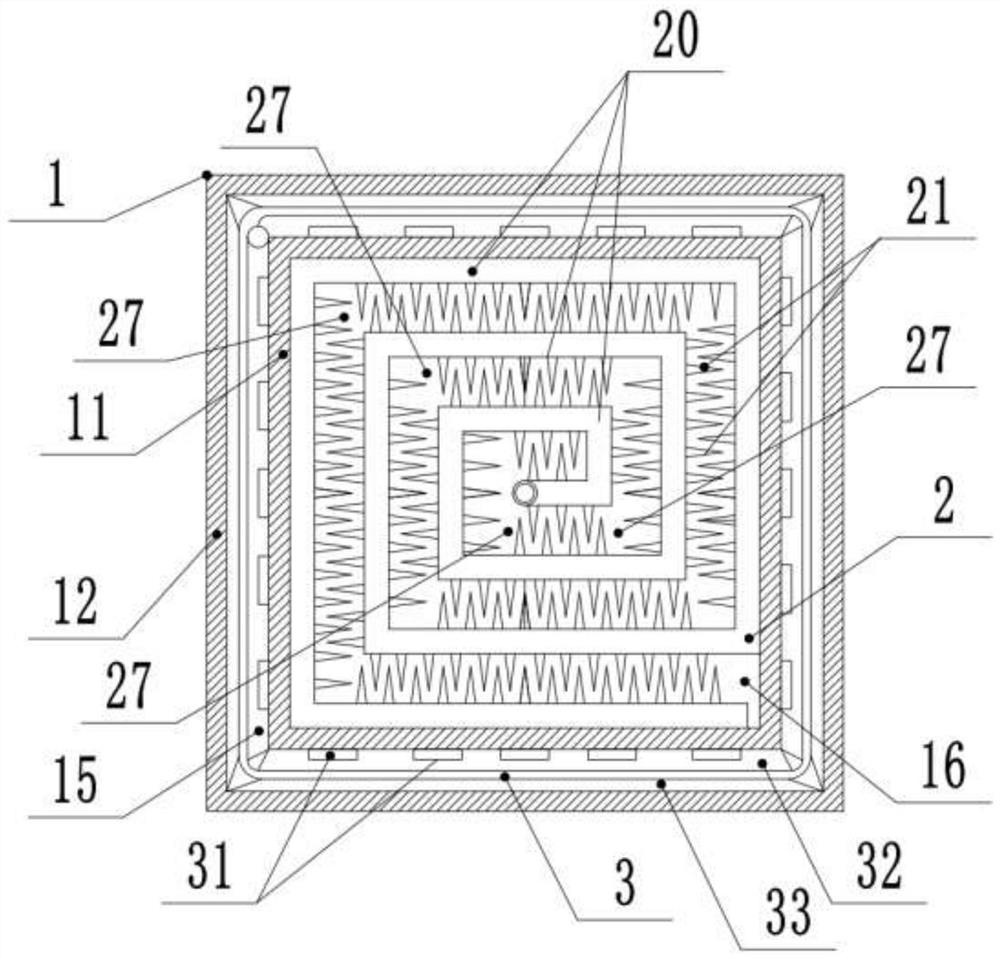

[0033]A hot heater combustion chamber based on high thermal radiant coefficient coating, such asfigure 1 withfigure 2 As shown, including the combustion chamber main body 1, heat exchanger structure 2, heat radiation utilization structure 3;

[0034]The combustion chamber main body 1 includes an inner casing 11 and a housing 12, an inner casing 11 and a housing 12 to be connected by a cover 13 and a lower cover 14, and a closed annular passage 15 is formed between the inner housing 11 and the outer casing 12. The inner casing 11 is provided with a combustion chamber body 16, and the upper portion of the inner casing 11 is provided with a gas inlet 17 and an air inlet 18. The inner casing 11 is provided with an exhaust port 19;

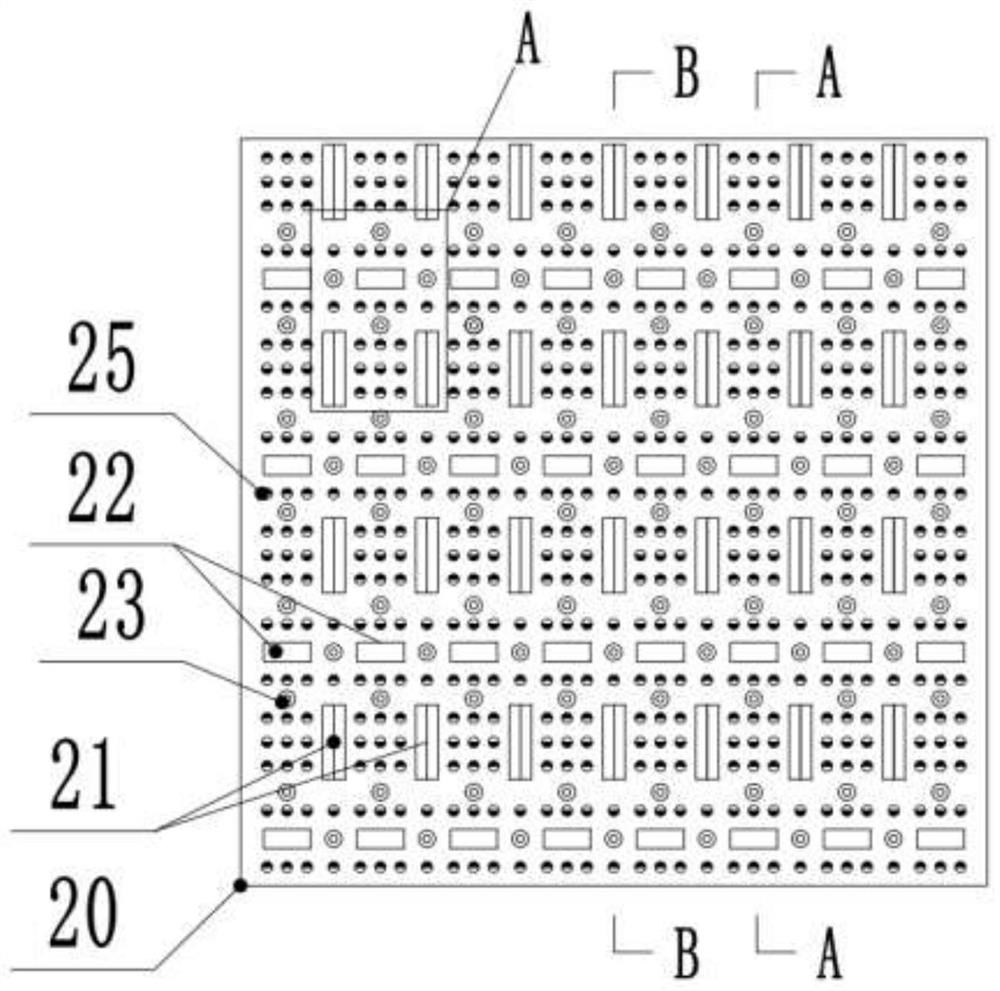

[0035]The heat exchange structure 2 includes a heat exchange plate 20 which is a spiral formation of a spiral formation in the axis of the combustion chamber 16, such asfigure 2 As shown, the outer ring layer of the heat exchange plate 20 is closely bonded to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com