An inductive liquid metal electromagnetic flowmeter

An electromagnetic flowmeter and liquid metal technology, applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effects, liquid/fluid solid measurement, etc., can solve the temperature resistance limit, limit convenience and economy And other problems, to achieve the effect of accurate measurement signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The present invention will be further described in detail below with reference to the accompanying drawings and specific examples.

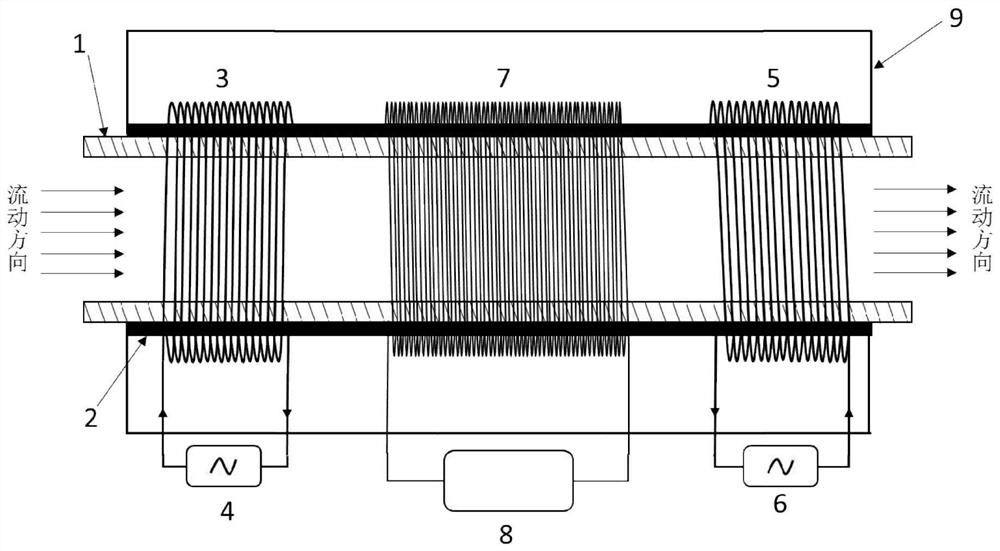

[0018]Such asfigure 1As shown, the present invention is an inductive liquid metal electromagnetic flowmeter comprising: a circular flow channel 1; a heat insulating layer 2; a first excitation coil 3; a first excitation power supply 4; a second excitation coil 5; second excitation Power supply 6; induction signal pickup coil 7; signal processing module 8; shield layer 9. The first excitation coil 3 is wrapped around both ends of the circular flow channel 1, and the first excitation power source 4 connects the first excitation coil 3, providing high frequency alternating current, the second excitation power source 6 connection for the first excitation coil 3. The second excitation coil 5 provides a high frequency alternating current for the second excitation coil 5; the first excitation coil 3 and the second excitation coil 5 are in the opposite dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com