Method for increasing baking aroma substance in aerosol gas-phase substances of heated cigarettes

A technology of gaseous substances and aerosols, which is applied in the fields of tobacco, tobacco preparation, food science, etc., to achieve the effect of simple and easy method, increasing content and proportion, and increasing the aroma and aroma of smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The burley tobacco raw material is pulverized into 300 meshes, the burley tobacco which is pulverized with a mass percentage of 15% of the raw material for sheet production is added to the raw material for production of thin slices by the thick pulp method, mixed evenly, and thick pulp containing burley tobacco is prepared according to the production process of thin slices by the thick pulp method. Pulp thin slices, cut into strips as the core material of central heating cigarettes, and rolled into heating cigarettes.

[0017] Control sample: no burley tobacco was added to the raw material, and the thick pulp sheet containing burley tobacco was prepared according to the same thick pulp sheet production process, which was used as the core material of the central heating cigarette, and rolled into a heating cigarette.

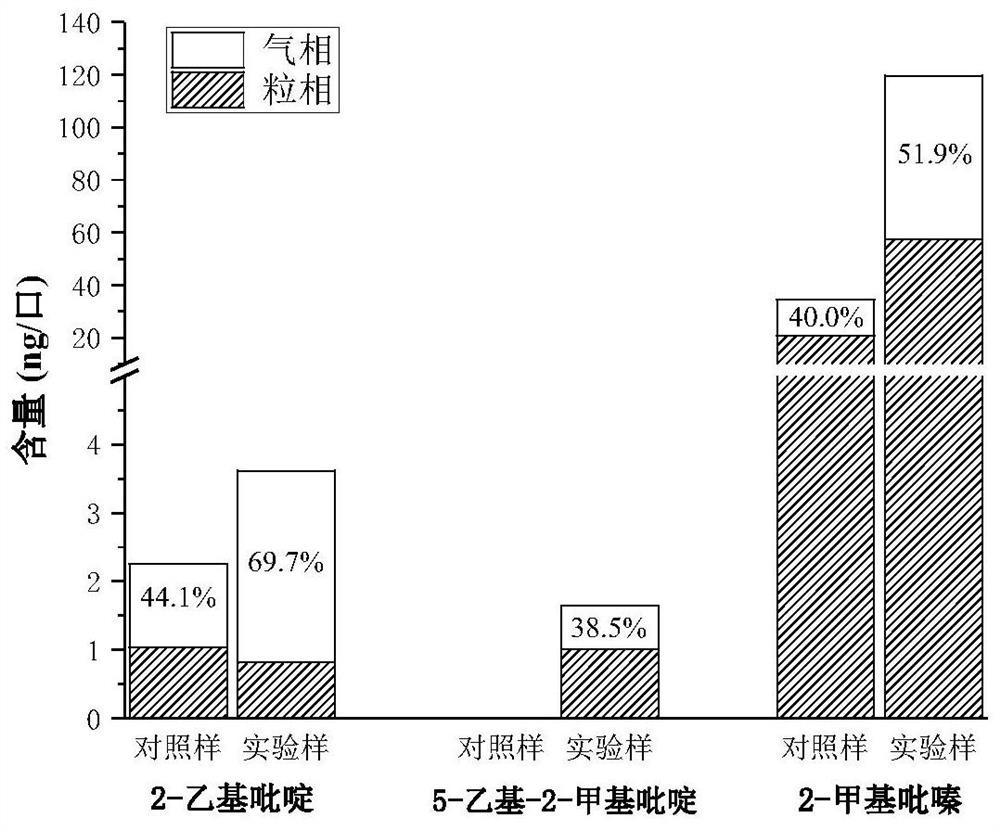

[0018] figure 1 The comparison chart of the roasted aroma substances in the heated cigarette smoke aerosol and the control sample prepared for the thick p...

Embodiment 2

[0020] The burley tobacco raw material is pulverized into 200 meshes, and the burley tobacco crushed with a mass percentage of 30% of the raw material for flake production is added to the raw material for production of flakes by the rolling method, mixed evenly, and prepared into a roll containing burley tobacco according to the production process of the flakes by the rolling method Pressed thin slices, cut into shreds, used as the core material of circumferentially heated cigarettes, and rolled into heated cigarettes.

[0021] Control sample: no burley tobacco was added to the raw material, and the rolling sheet containing burley tobacco was prepared according to the same rolling sheet production process, which was used as the core material of the central heating cigarette, and rolled into a heating cigarette.

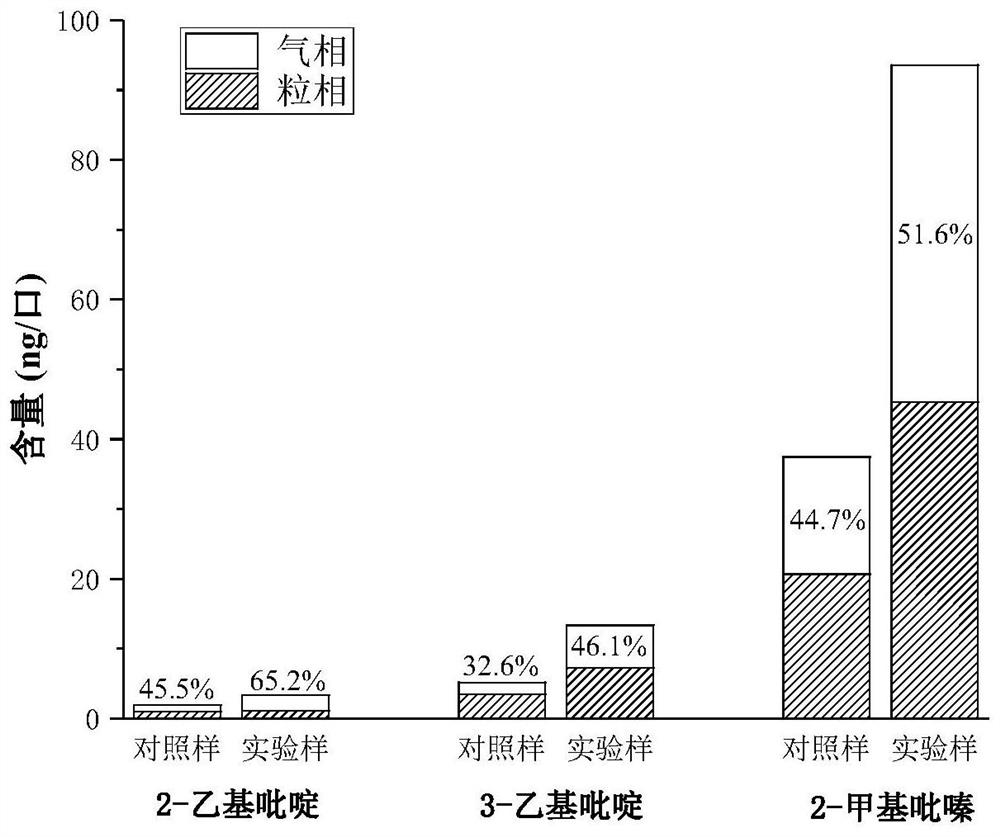

[0022] figure 2 The comparison chart of the roasted aroma substances in the smoke aerosol of the heated cigarette prepared by the rolling method sheet added with Bur...

Embodiment 3

[0024] After the prepared Burley tobacco is cut into shreds, it is blended into heated cigarette shreds according to the proportion of 8% of the mass percentage of heated cigarette shreds, and rolled according to the heated cigarette rolling process to make burley tobacco with a proportion of 8% circumferential heating. type heated cigarettes.

[0025] Control sample: a circumferential heating type heating cigarette rolled by the same rolling process without blending burley tobacco in the shredded tobacco of the heated cigarette.

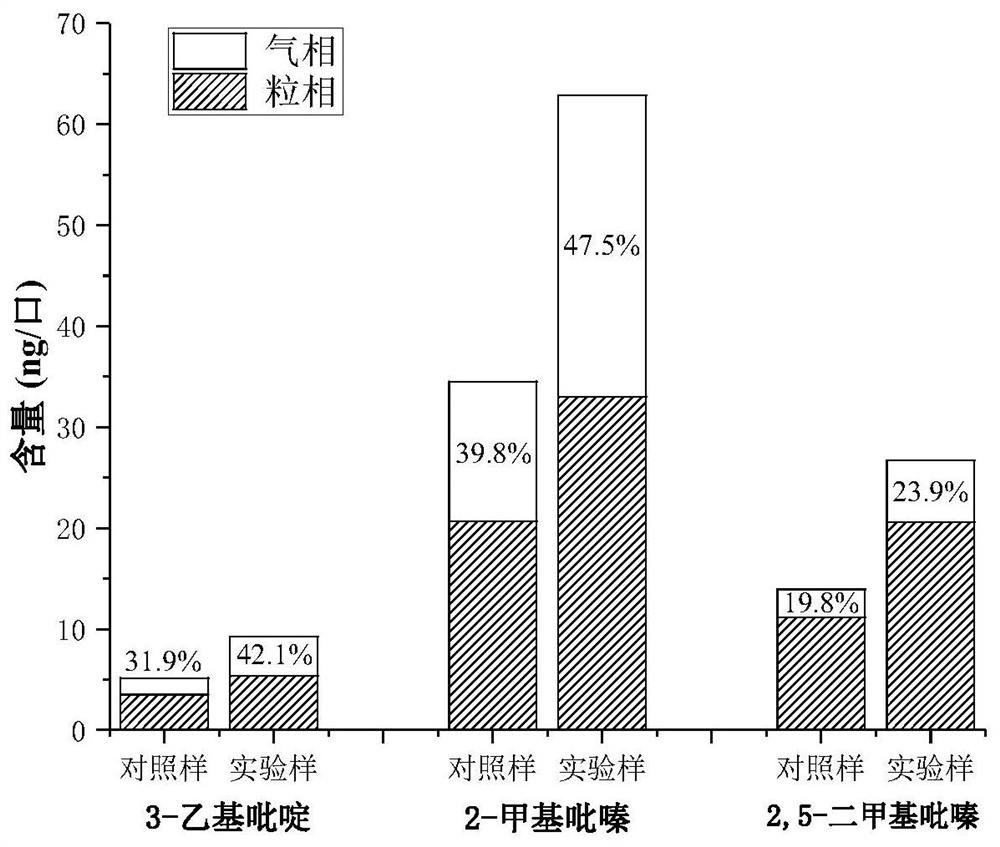

[0026] image 3 This is a comparison chart of the roasted aroma substances in the smoke aerosol and the control sample after blending 8% Burley tobacco shredded tobacco in the heated cigarette. The results show that the representative roasted aroma substance 3-ethylpyridine in the gas phase of the smoke aerosol The content has increased by 2.24ng / mouth, and the ratio in the gas phase has increased by 10.2%; the content of 2-methylpyrazine in the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com