High-reduction-degree porous ceramic atomizing core and preparation method thereof

A technology of porous ceramics and atomizing cores, applied in ceramic products, other household appliances, applications, etc., can solve the problems of insufficient reduction degree and poor user experience, and achieve reasonable size, high fragrance reduction degree, and full mist beads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

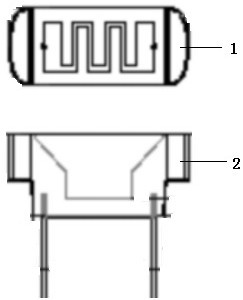

Image

Examples

Embodiment 1

[0022] The preparation method of the porous ceramic atomizing core with high reduction degree described in this example is as follows:

[0023] Step 1. Select the mixture according to the number of parts by mass, including 10 parts of silicon carbide, 11 parts of alumina, 24 parts of quartz glass, 12 parts of molten glass powder, and 7 parts of pore-forming agent; the selection principle is that each component has different shapes and sharp edges and corners , to ensure the diversity of voids and the adsorption of the ceramic body to the atomized liquid; and to fragment these components;

[0024] Step 2: Melt the mixed wax solvent at 60-70°C, add 0.5%~1% oleic acid by mass, measure 50 parts of the molten material, add solvent to the molten material to make the molten material into a paste, and wait until the molten material is mixed with After the oleic acid is uniformly dispersed, add the mixture selected in step 1, continue stirring, and stir for more than 6 hours to obtain ...

Embodiment 2

[0034] The preparation method of the porous ceramic atomizing core with high reduction degree described in this example is as follows:

[0035] Step 1. Select the mixture according to the number of parts by mass, including 21 parts of silicon carbide, 24 parts of alumina, 38 parts of quartz glass, 18 parts of molten glass powder, and 26 parts of pore-forming agent; the selection principle is that each component in the mixture has different shapes , clear edges and corners to ensure the diversity of voids and the adsorption of the ceramic body to the atomized liquid; and fragmentation of these components;

[0036] Step 2: Melt the mixed wax solvent at 60-70°C, add 0.5%~1% oleic acid by mass, measure 100 parts of the molten material, add solvent to the molten material to make the molten material into a paste, and wait until the molten material is mixed with After the oleic acid is uniformly dispersed, add the mixture selected in step 1, continue stirring, and stir for more than ...

Embodiment 3

[0046] The preparation method of the porous ceramic atomizing core with high reduction degree described in this example is as follows:

[0047]Step 1. Select the mixture according to the number of parts by mass, including 15 parts of silicon carbide, 15 parts of alumina, 24 parts of quartz glass, 12 parts of molten glass powder, and 7 parts of pore-forming agent; the selection principle is that each component in the mixture has different shapes , clear edges and corners to ensure the diversity of voids and the adsorption of the ceramic body to the atomized liquid; and fragmentation of these components;

[0048] Step 2: Melt the mixed wax solvent at 60-70°C, add 0.5%~1% oleic acid by mass, measure 100 parts of the molten material, add solvent to the molten material to make the molten material into a paste, and wait until the molten material is mixed with After the oleic acid is uniformly dispersed, add the mixture selected in step 1, continue stirring, and stir for more than 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com