Folk culture full-automatic beaten iron openwork and scrap iron recycling system

A recovery system and iron flower technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of inability to accurately control the heating of molten iron, lack of automatic control, and difficulty in achieving performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Typical implementations of the present invention will be described below in conjunction with specific drawings.

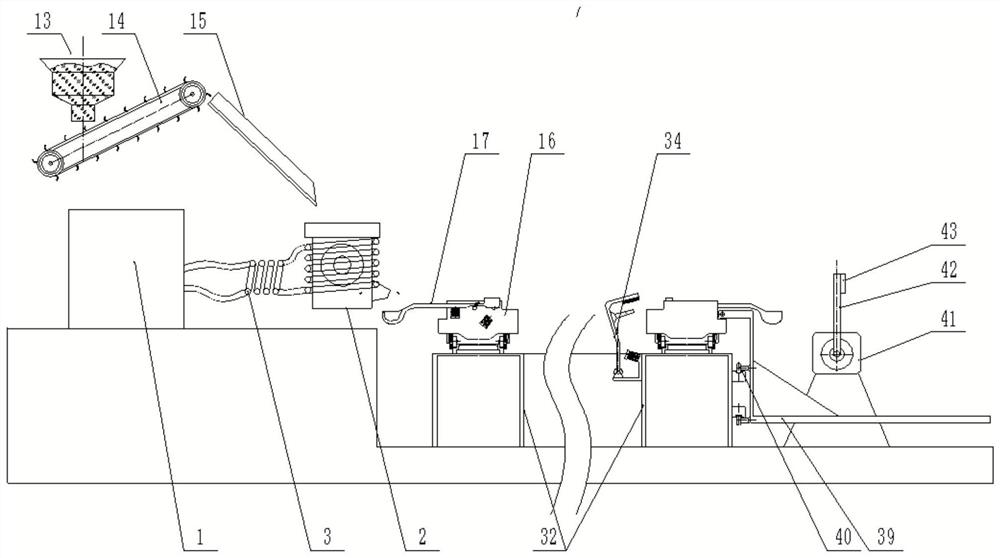

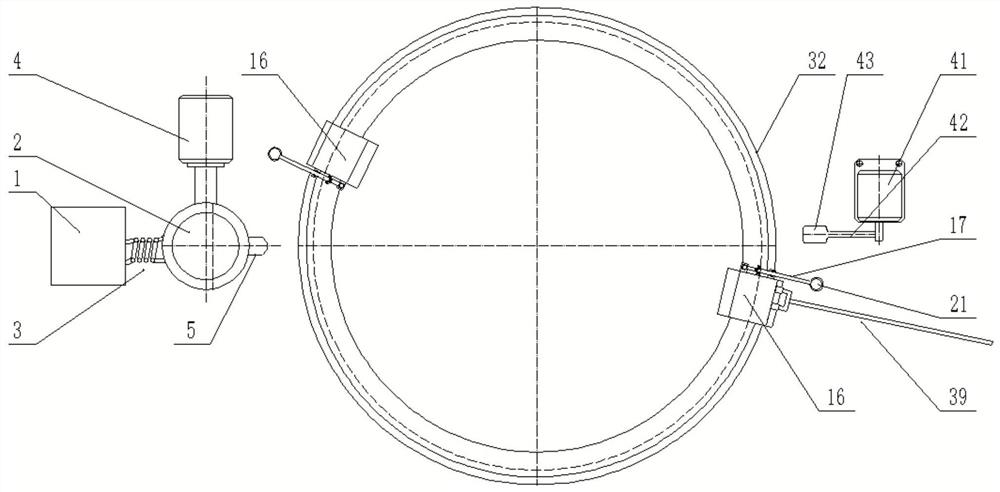

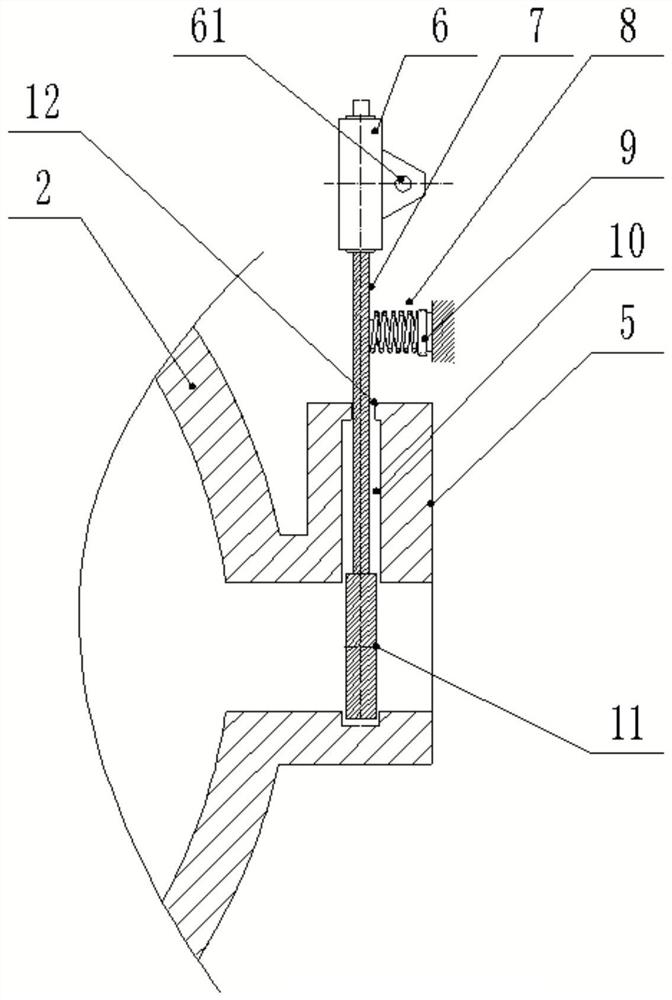

[0029] Such as Figure 1-8 And as shown in A-C:

[0030] The present invention mainly consists of a control cabinet (1), an intermediate frequency furnace (2), a turning furnace motor (4), a melting port switch drive mechanism (6), a graphite baffle (11), a circulating trolley (16), a melt spoon ( 17), track frame (32), impact motor (41), impact hammer (42), clutch linear drive mechanism (22), Y-shaped clutch frame (23, 37), electromagnetic collecting rod (39), F limit Bit fork (34) forms.

[0031] The turning furnace motor (4) is connected to the intermediate frequency furnace (2) through a coupling, and controls the turning of the intermediate frequency furnace (2), so that the melt can be controlled to flow out of the melt outlet (5). The control cabinet (1) is connected to the intermediate frequency furnace (2) and the intermediate frequency furnace c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com