A kind of bamboo wood fiber negative ion decorative line board

A technology for decorative strips and bamboo and wood fibers, applied in the field of decorative materials, can solve the problems of poor wear resistance, poor interface compatibility, poor environmental protection performance, etc., achieve long service life, good impact resistance, and reduce harmful substances. release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

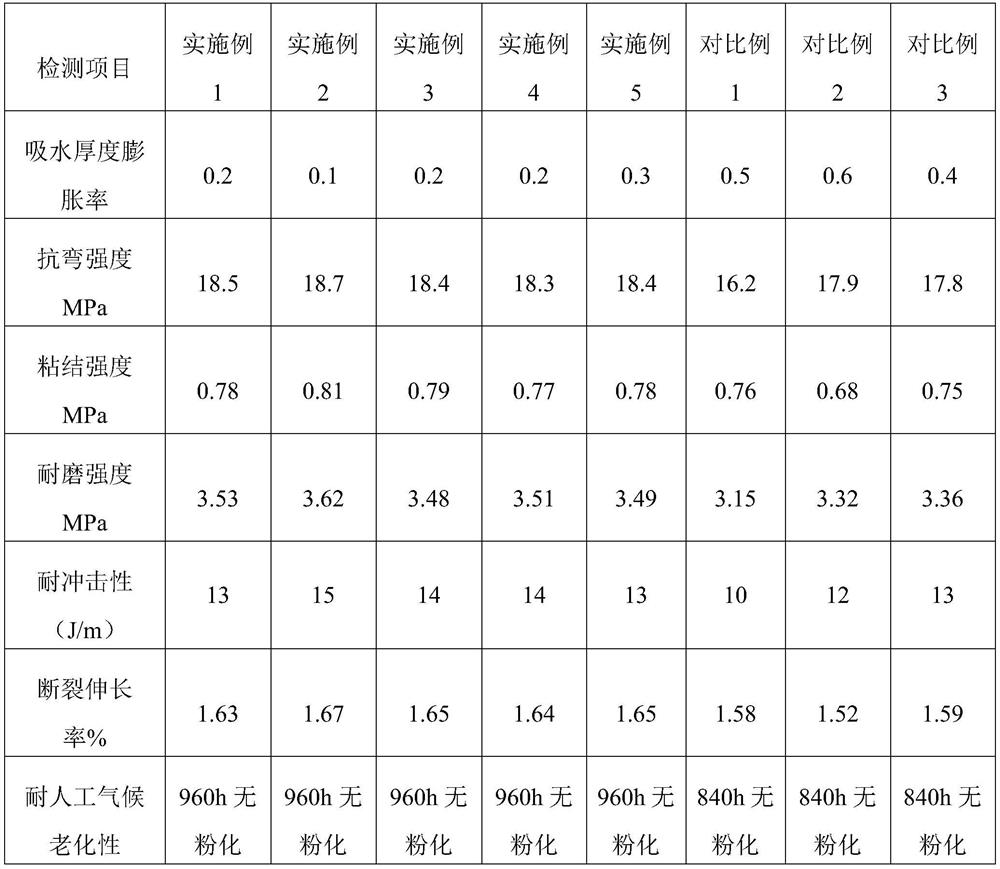

Examples

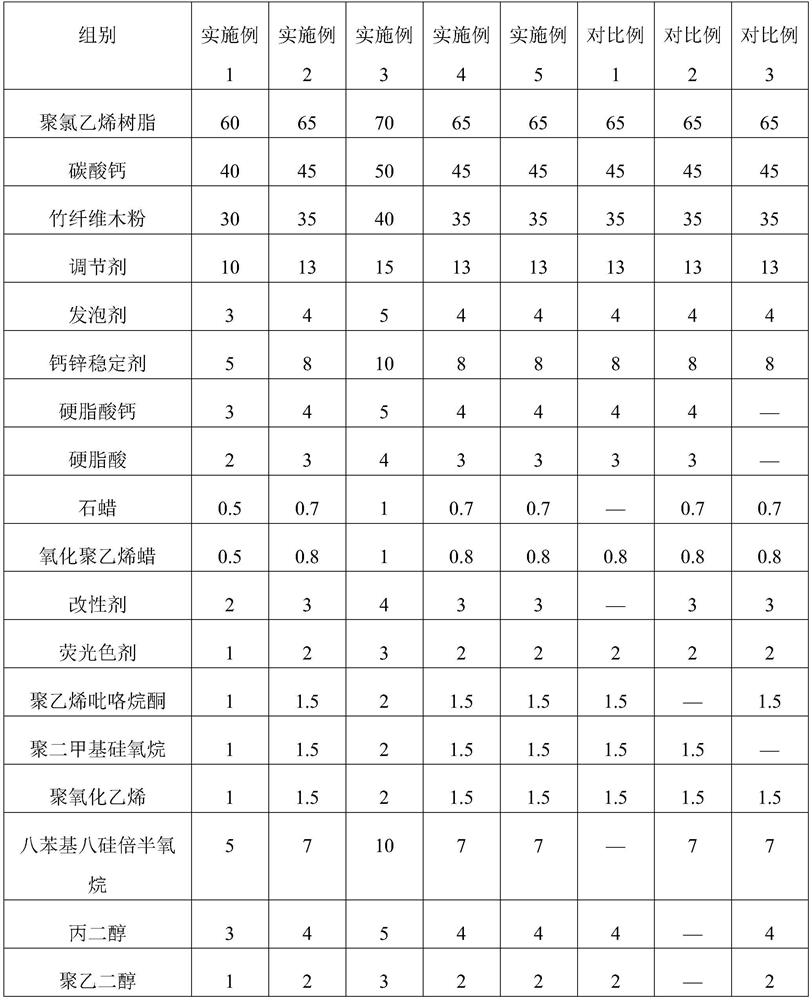

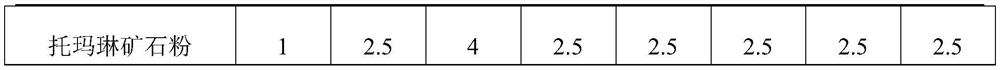

Embodiment 1

[0031] A kind of bamboo wood fiber negative ion decorative line board is made up of the following components by weight:

[0032] 60 parts of polyvinyl chloride resin, 40 parts of calcium carbonate, 30 parts of bamboo fiber wood powder, 10 parts of HL-100, 3 parts of foaming agent, 5 parts of calcium zinc stabilizer, 3 parts of calcium stearate, 2 parts of stearic acid , 0.5 parts of paraffin wax, 0.5 parts of oxidized polyethylene wax, 2 parts of modifier, 1 part of tetraphenylethylene, 1 part of polyvinylpyrrolidone, 1 part of polydimethylsiloxane, 1 part of polyethylene oxide, octaphenyl octane 5 parts of silsesquioxane, 3 parts of propylene glycol, 1 part of polyethylene glycol, 1 part of tourmaline ore powder, wherein the particle size of bamboo fiber wood powder is 100-200 mesh, and the modifier is ACR and CPE quality A mixture with a ratio of 1:1.

[0033] Its preparation method comprises the following steps:

[0034] S1, according to the formula of above-mentioned a k...

Embodiment 2

[0040] A kind of bamboo wood fiber negative ion decorative line board is made up of the following components by weight:

[0041] 65 parts of polyvinyl chloride resin, 45 parts of calcium carbonate, 35 parts of bamboo fiber wood powder, 13 parts of HL-100, 4 parts of foaming agent, 8 parts of calcium zinc stabilizer, 4 parts of calcium stearate, 3 parts of stearic acid , 0.7 parts of paraffin, 0.8 parts of oxidized polyethylene wax, 3 parts of modifiers, 2 parts of tetraphenylethylene, 1.5 parts of polyvinylpyrrolidone, 1.5 parts of polydimethylsiloxane, 1.5 parts of polyethylene oxide, octaphenyl octane 7 parts of silsesquioxane, 4 parts of propylene glycol, 2 parts of polyethylene glycol, 2.5 parts of tourmaline ore powder, wherein the particle size of bamboo fiber wood powder is 100-200 mesh, and the modifier is ACR and CPE quality A mixture with a ratio of 1:1.

[0042] Its preparation method is with embodiment 1.

Embodiment 3

[0044] A kind of bamboo wood fiber negative ion decorative line board is made up of the following components by weight:

[0045] 70 parts of polyvinyl chloride resin, 50 parts of calcium carbonate, 40 parts of bamboo fiber wood powder, 15 parts of HL-100, 5 parts of foaming agent, 10 parts of calcium zinc stabilizer, 5 parts of calcium stearate, 4 parts of stearic acid , 1 part of paraffin wax, 1 part of oxidized polyethylene wax, 4 parts of modifier, 3 parts of tetraphenylethylene, 2 parts of polyvinylpyrrolidone, 2 parts of polydimethylsiloxane, 2 parts of polyethylene oxide, octaphenyl octasil 10 parts of sesquioxane, 5 parts of propylene glycol, 3 parts of polyethylene glycol, 4 parts of tourmaline ore powder, wherein the particle size of bamboo fiber wood powder is 100-200 mesh, and the modifier is the mass ratio of ACR and CPE for a 1:1 mixture.

[0046] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com