Rare earth metal electrochromic film electrode and preparation method and application thereof

An electrochromic, rare earth metal technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of poor weather resistance, light color, easy aging and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

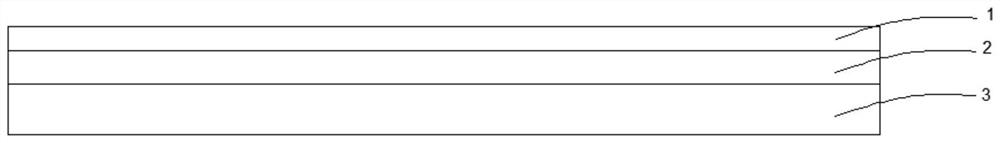

[0026] This embodiment provides a rare earth metal electrochromic thin film electrode, its structure is as follows figure 1 As shown, the transparent color-changing functional layer 1, the transparent conductive layer 2 and the substrate 3 are in the order of top and bottom; the transparent color-changing functional layer 1 is formed by mixing rare earth color-changing metal W and interstitial metal Ni. The thickness of the transparent color-changing functional layer is 25nm. The transparent conductive layer is an ITO layer with a thickness of 20nm. The tetragonal resistance of the ITO layer is 100Ω. The base material is PET, the thickness is 30 μm, and the thickness error is not more than 5 μm. The mass content W of the rare earth color-changing metal in the transparent color-changing functional layer is 92%, and the mass content of the interstitial metal Ni is 8wt%. The preparation method of this film electrode is:

[0027] (1) Form a transparent conductive layer on the ...

Embodiment 2

[0032] This embodiment provides a rare earth metal electrochromic thin film electrode, its structure is as follows figure 1 As shown, there are transparent color-changing functional layer 1, transparent conductive layer 2 and substrate 3 in the order of top and bottom; transparent color-changing functional layer 1 is made of rare earth color-changing metal Nb 2 o 5 Mixed with interstitial metal Ti. The thickness of the transparent color-changing functional layer is 20nm. The transparent conductive layer is an ITO layer with a thickness of 30nm. The tetragonal resistance of the ITO layer is 200Ω. The base material is PET, the thickness is 50 μm, and the thickness error is not more than 5 μm. The mass content of rare earth color-changing metal Nb in the transparent color-changing functional layer 2 o 5 W is 85%, and the mass content of interstitial metal Ti is 15wt%. The preparation method of this film electrode is:

[0033] (1) Form a transparent conductive layer on the...

Embodiment 3

[0038] This embodiment provides a rare earth metal electrochromic thin film electrode, its structure is as follows figure 1 As shown, the transparent color-changing functional layer 1, the transparent conductive layer 2 and the substrate 3 are followed in the order of top and bottom; the transparent color-changing functional layer 1 is made of rare earth color-changing metal IrO 2 and interstitial metal Ta 2 o 5 mixed. The thickness of the transparent color-changing functional layer is 30nm. The transparent conductive layer is an ITO layer with a thickness of 10nm. The tetragonal resistance of the ITO layer is 80Ω. The base material is PET, the thickness is 100 μm, and the thickness error is not more than 5 μm. The mass content IrO of the rare earth discoloration metal in the transparent discoloration functional layer 2 W is 80%, interstitial metal Ta 2 o 5 The mass content is 20wt%. The preparation method of this film electrode is:

[0039] (1) Form a transparent co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com