Sweepforward front edge type side plate structure matched with binary supersonic air inlet channel

A supersonic inlet, dual-type technology, applied in the field of aerodynamics, can solve the problem of changing the two-dimensional flow characteristics of the inlet, the difference in the recovery coefficient of the total pressure of the inlet, and the lateral overflow of the compression section of the inlet, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

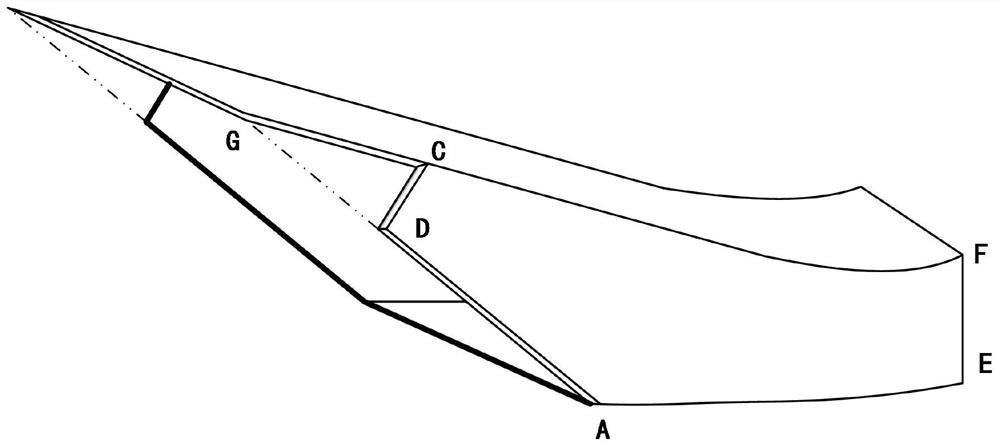

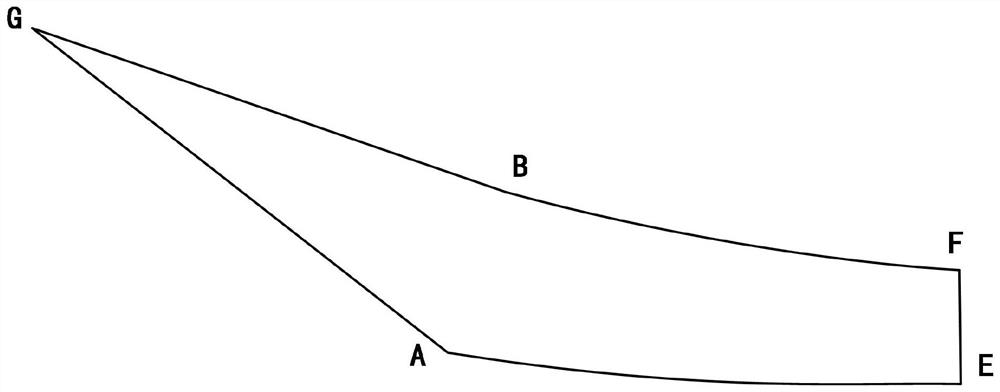

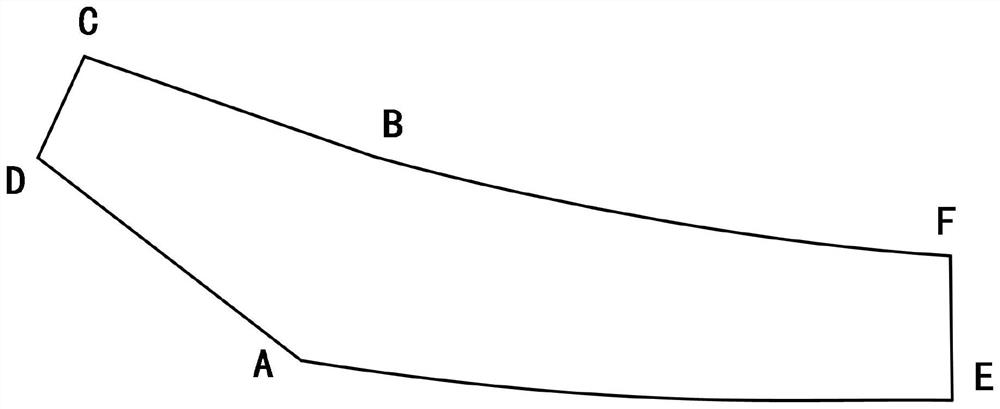

[0037] Embodiment: Based on the traditional binary supersonic inlet, in order to weaken the lateral overflow effect in front of the lip, side plate structures are often added on both sides of the front body of the inlet to reduce the lateral overflow of the compression section and weaken the intake The three-dimensional flow effect of the channel is used to ensure the two-dimensional characteristics of the flow field in the compression section. Although in general, with the increase of side plate shading, the flow capture coefficient of the intake will increase. But at the same time, after the airflow passes through the precursor, the boundary layer becomes thicker. Under the cover of the side plate, the low-energy flow of the boundary layer can continue to develop, which will cause the total pressure recovery coefficient of the inlet port to be poor. Therefore, this embodiment redesigns the structure of the side plate, and the main idea is to design the front edge line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com