Pasting method of punching net grid for lead-acid storage battery

A technology of lead-acid batteries and grids, which is applied in coatings, electrode carriers/collectors, devices for coating liquid on the surface, etc., and can solve problems such as the difficulty in combining lead paste with the grid surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A paste coating method for punching grids for lead-acid batteries includes the following steps:

[0022] Step 1. The whole lead strip with a certain thickness is then punched to form a continuous grid strip with a punch, and the grid strip is wound into a roll;

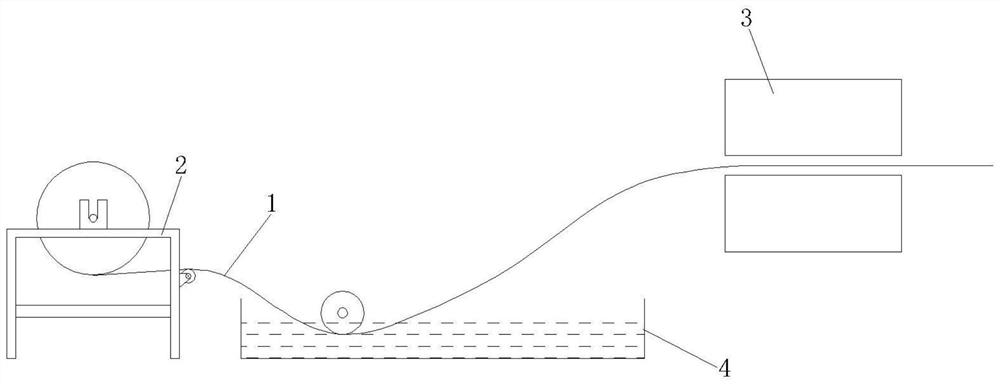

[0023] Step 2, such as figure 1 As shown, the wound grid tape 1 is placed on the support frame 2 for unwinding, and then the unrolled grid tape 1 is horizontally conveyed to the paste coating machine 3, and the grid tape is placed on the support frame 2 A water tank 4 is arranged between the paste coating machine 3 and the water tank 4 is filled with sodium hydroxide solution, so that the part of the grid strip 1 on the water tank is bent down, and part of the body of the grid strip 1 is sunk into the water tank 4 It is filled with sodium hydroxide solution, so that the surface of the continuously conveyed grid strip 1 is soaked with sodium hydroxide solution after passing through the water tank 4; from the grid str...

Embodiment 2

[0026] A paste coating method for punching grids for lead-acid batteries includes the following steps:

[0027] Step 1. The whole lead strip with a certain thickness is then punched to form a continuous grid strip with a punch, and the grid strip is wound into a roll;

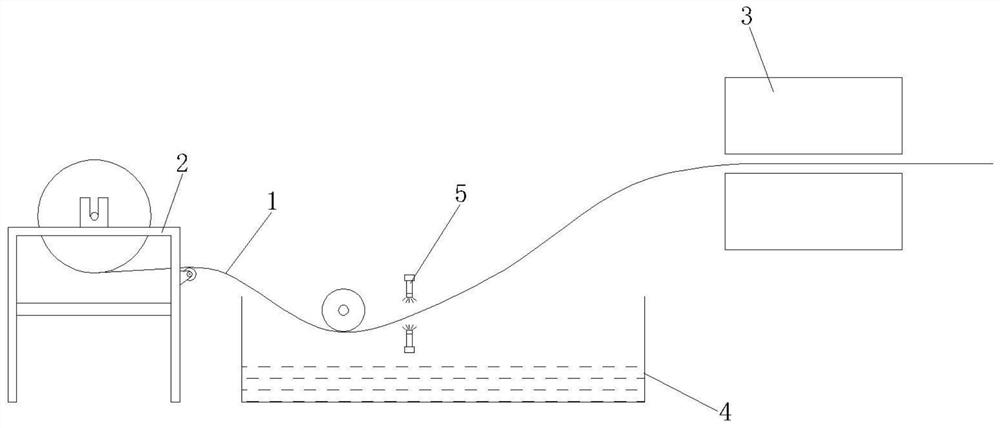

[0028] Step 2, such as figure 2 As shown, the wound grid tape 1 is placed on the support frame 2 for unwinding, and then the unrolled grid tape 1 is horizontally conveyed to the paste coating machine 3, and the grid tape is placed on the support frame 2 A water tank 4 is installed between the paste coating machine 3 and the water tank 4 is filled with sodium hydroxide solution, so that spray heads 6 are provided above and below the part of the grid strip 1 on the water tank 4, and the spraying directions of the spray heads 6 are respectively facing On the upper and lower surfaces of the grid strip 1, the nozzle 6 sprays sodium hydroxide solution on the upper and lower surfaces of the grid strip, so that the continu...

Embodiment 3

[0031] A paste coating method for punching grids for lead-acid batteries includes the following steps:

[0032] Step 1. The whole lead strip with a certain thickness is then punched to form a continuous grid strip with a punch, and the grid strip is wound into a roll;

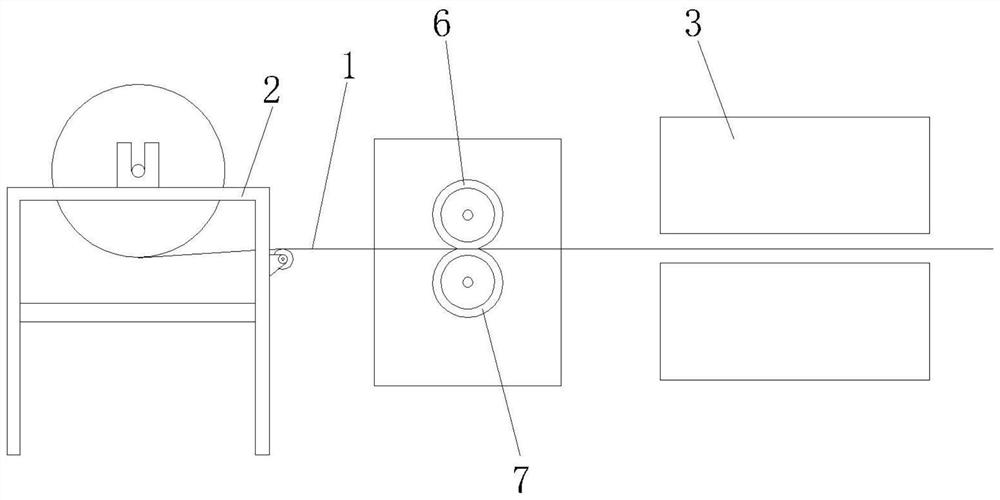

[0033] Step 2, such as image 3 As shown, the wound grid tape 1 is placed on the support frame 2 for unwinding, and then the unrolled grid tape 2 is horizontally conveyed to the paste coating machine 3, and the grid tape is placed on the support frame 2 A brushing device is arranged between the coating machine 3 and the coating device. The brushing device includes an upper brushing wheel 6 and a lower brushing wheel 7. The surfaces of the upper brushing wheel 6 and the lower brushing wheel 7 are provided with bristles. The upper brushing wheel 6 is located above the grid belt 1 and the lower edge of the upper brushing wheel 6 abuts the upper surface of the grid belt 1; the lower brushing wheel 7 is located below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com