A purification exhaust device based on hot-dip galvanizing production line

A technology of exhaust device and production line, applied in the direction of combination device, hot dip plating process, chemical instrument and method, etc., can solve the problems of no gas spraying, easy splashing of liquid, inconvenient heating of thermal insulation pool, etc. Purifying effect, improving protection effect, improving effect of eliminating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

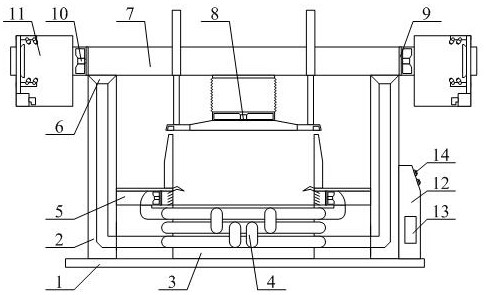

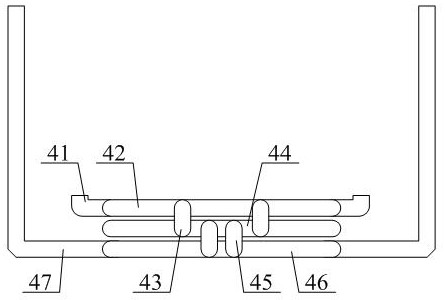

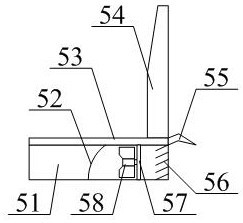

[0042] as attached figure 1 And attached Figure 4 shown

[0043] The invention provides a purification and exhaust device based on a hot-dip galvanizing production line, including a reinforced bottom plate 1, a side temperature insulation plate frame 2, a galvanizing pool 3, a heat-conducting transport frame structure 4, a side splash guard structure 5, and an air outlet cover 6 , top pipe 7, adjustable protective frame structure 8, longitudinal rod 9, longitudinal fan 10, side filter discharge frame structure 11, console 12, controller 13 and control button 14, the side temperature insulation plate frame 2 Bolts are installed on the left and right sides of the upper part of the reinforced bottom plate 1; the galvanized pool 3 is installed on the middle and upper part of the reinforced bottom plate 1; the heat-conducting conveyor structure 4 is installed on the outside of the galvanized pool 3; The splash frame structure 5 is installed in the inner middle position of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com