Flexible omnidirectional intelligent mobile equipment for series-parallel processing robot

A mobile equipment, omnidirectional movement technology, used in elastic suspension, transportation and packaging, vehicle maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

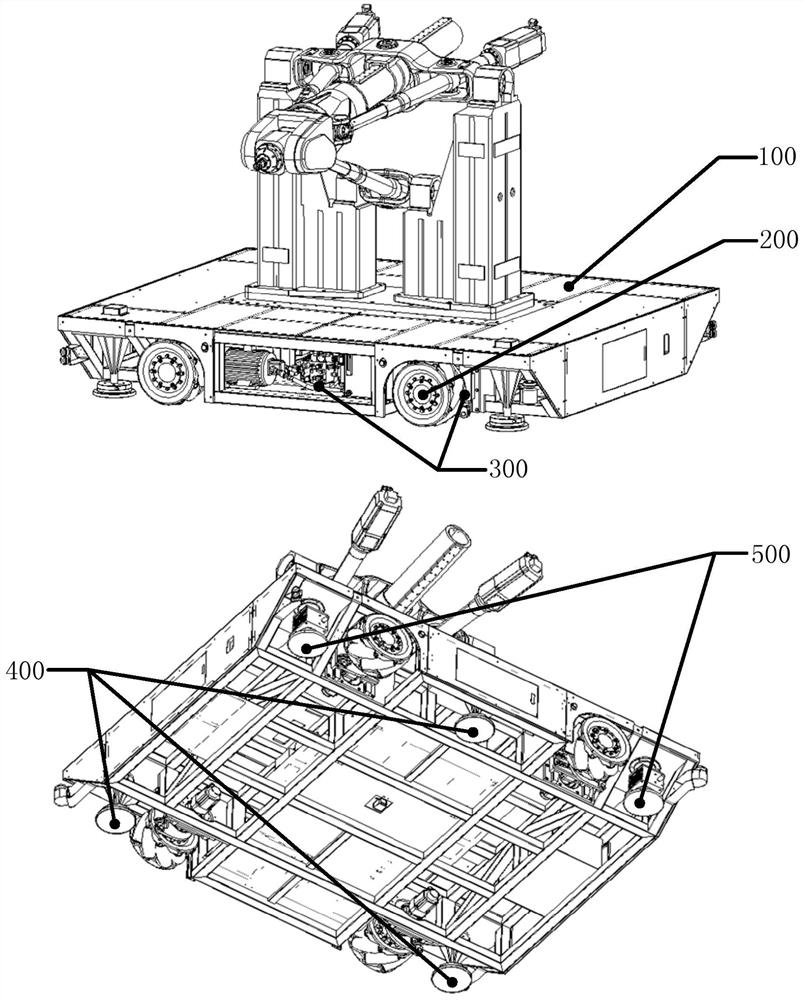

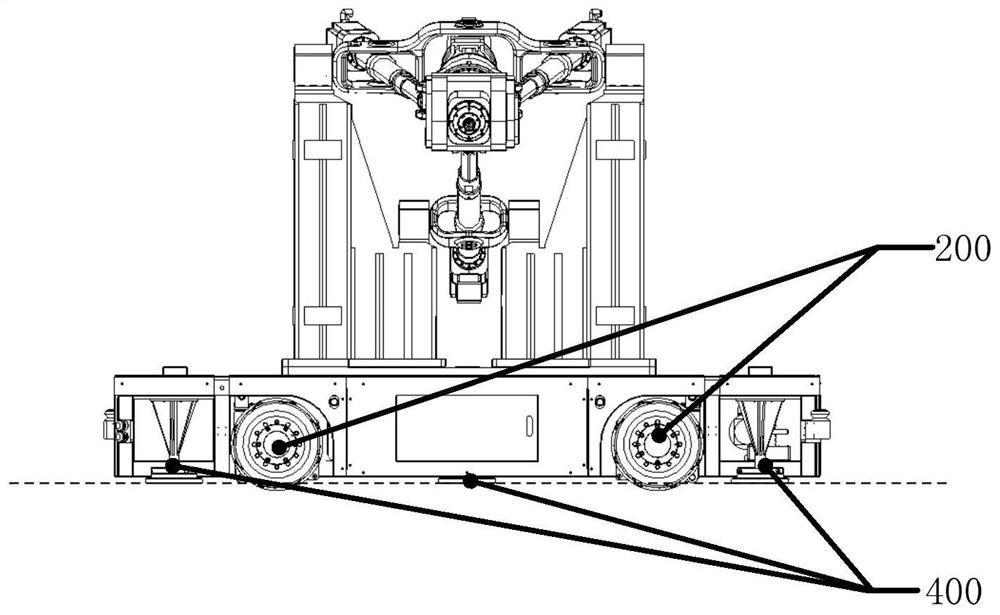

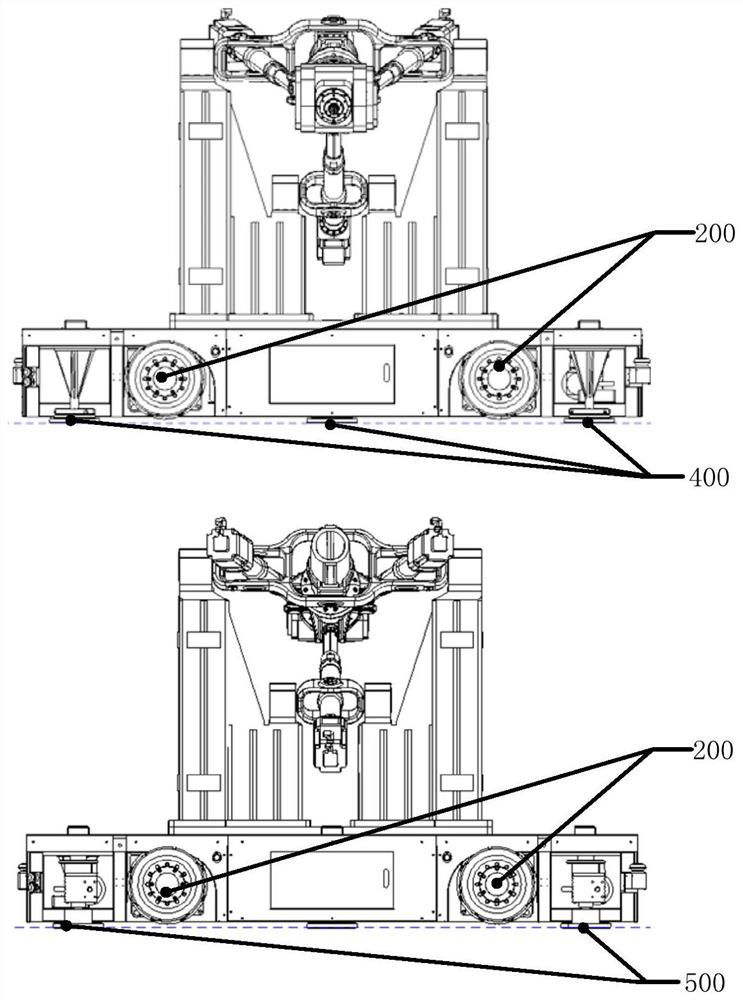

[0060] The invention is a flexible omnidirectional intelligent mobile equipment for hybrid processing robots, comprising: a chassis unit (100), an omnidirectional mobile unit (200), an active oil-gas suspension unit (300), a passive support unit (400), a force Sensing support unit (500); omnidirectional intelligent mobile equipment, divided into standby mode, mobile mode and working mode; equipment enters standby mode, and the chassis unit (100) is independently supported by passive support unit (400); equipment enters mobile mode , before the robot moves to the designated station, the chassis unit (100) is independently supported by the passive support unit (400) and switched to the sole support of the chassis unit (100) by the omnidirectional mobile unit (200); the omnidirectional mobile unit (200) will The robot moves to the designated sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com