Application method for rapid dehydration of urban river silt

A technology for rapid dehydration of river silt, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as long construction period and occupied site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

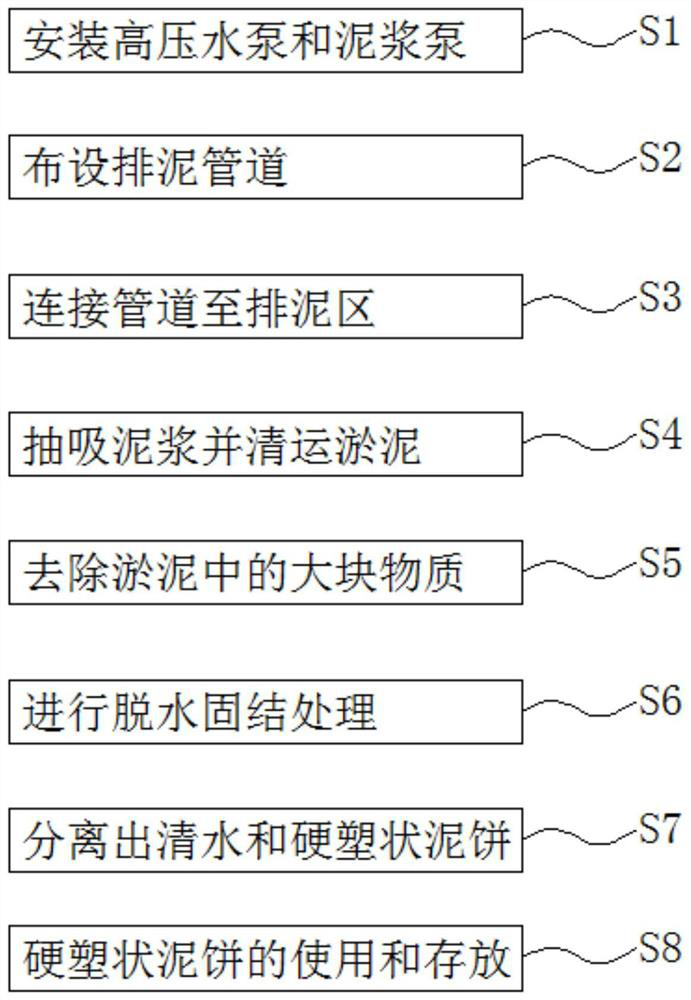

[0026] see figure 1 , an application method for rapid dehydration of urban river silt, comprising the following steps:

[0027] S1. Install high-pressure water pumps and mud pumps on the mud flushing working face, lay rubber nylon pipes for mud discharge, and draw clean water to supply water for high-pressure pumps. After the mud pumps pump mud, return water is available for use;

[0028] S2. Start the high-pressure pump and use the water gun to flush the ground with the mud to form a pool, and arrange a mud discharge pipeline. The mud discharge pipeline is mainly made of underwater submerged pipes, with a small amount of floating pipes and land pipes;

[0029] S3. The underwater submersible pipe is connected to the floating pipe on the water, and connected to the land pipe to extend to the mud discharge area;

[0030] S4. Put down the mud pump to suck the mud, transport it to the mud discharge area through the mud discharge pipeline, and then clear and transport the mud thro...

Embodiment 2

[0042] An application method for rapid dehydration of urban river silt, comprising the following steps:

[0043] S1. Install high-pressure water pumps and mud pumps on the mud flushing working face, lay rubber nylon pipes for mud discharge, and draw clean water to supply water for high-pressure pumps. After the mud pumps pump mud, return water is available for use;

[0044] S2. Start the high-pressure pump and use the water gun to flush the ground with the mud to form a pool, and arrange a mud discharge pipeline. The mud discharge pipeline is mainly made of underwater submerged pipes, with a small amount of floating pipes and land pipes;

[0045] S3. The underwater submersible pipe is connected to the floating pipe on the water, and connected to the land pipe to extend to the mud discharge area;

[0046] S4. Put down the mud pump to suck the mud, transport it to the mud discharge area through the mud discharge pipeline, and then clear and transport the mud through the mud tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com