Preparation method of graphene-based waterborne epoxy resin emulsion

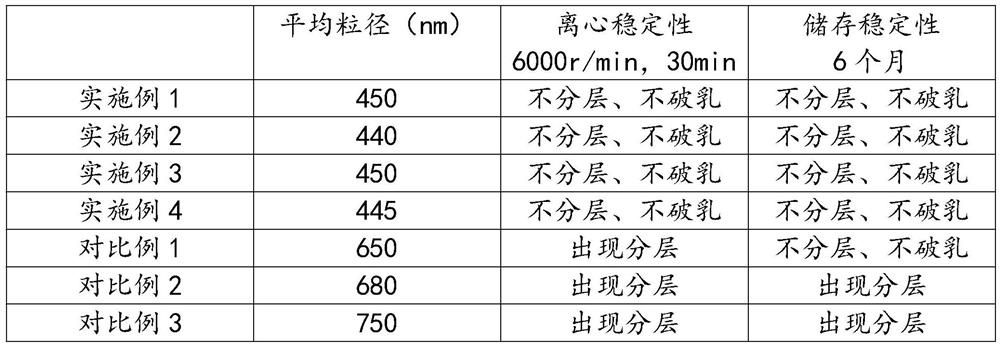

A water-based epoxy resin and epoxy resin technology, applied in the field of preparation of water-based epoxy resin emulsion, can solve the problems of storage stability and application performance, large particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method based on graphene-based aqueous epoxy resin emulsion, comprising the steps:

[0031] The first step, weigh the following raw materials in parts by weight: 10 parts of modified graphene, 3 parts of emulsifier, 35 parts of epoxy resin, 5 parts of polyethylene glycol, 120 parts of propylene glycol methyl ether, 20 parts of deionized water, 1 part Boron trifluoride, 1 part GSK-550;

[0032] Step 2: Add epoxy resin to a beaker filled with propylene glycol methyl ether, heat in a water bath at 60°C and stir at a constant speed until a transparent solution is formed, then add emulsifier and polyethylene glycol, and continue stirring for 30 minutes;

[0033] Step 3: Add boron trifluoride and modified graphene, cool down to 30°C and stir at a constant speed for 10 minutes, then raise the temperature to 85°C, react at this temperature for 2 hours, then cool down to 60°C, add deionized water dropwise, and control The dropping time is 1h, stirring at a constant ...

Embodiment 2

[0043] A preparation method based on graphene-based aqueous epoxy resin emulsion, comprising the steps:

[0044] The first step, weigh the following raw materials by weight: 12 parts of modified graphene, 4 parts of emulsifier, 40 parts of epoxy resin, 8 parts of polyethylene glycol, 130 parts of propylene glycol methyl ether, 22 parts of deionized water, 1 part Boron trifluoride, 2 parts GSK-550;

[0045] Step 2: Add epoxy resin to a beaker filled with propylene glycol methyl ether, heat in a water bath at 60°C and stir at a constant speed until a transparent solution is formed, then add emulsifier and polyethylene glycol, and continue stirring for 30 minutes;

[0046] Step 3: Add boron trifluoride and modified graphene, cool down to 30°C and stir at a constant speed for 10 minutes, then raise the temperature to 85°C, react at this temperature for 2 hours, then cool down to 60°C, add deionized water dropwise, and control The dropping time is 1h, stirring at a constant speed ...

Embodiment 3

[0049] A preparation method based on graphene-based aqueous epoxy resin emulsion, comprising the steps:

[0050] The first step, weigh the following raw materials by weight: 14 parts of modified graphene, 4 parts of emulsifier, 45 parts of epoxy resin, 8 parts of polyethylene glycol, 140 parts of propylene glycol methyl ether, 28 parts of deionized water, 2 parts Boron trifluoride, 2 parts GSK-550;

[0051] Step 2: Add epoxy resin to a beaker filled with propylene glycol methyl ether, heat in a water bath at 60°C and stir at a constant speed until a transparent solution is formed, then add emulsifier and polyethylene glycol, and continue stirring for 30 minutes;

[0052] Step 3: Add boron trifluoride and modified graphene, cool down to 30°C and stir at a constant speed for 10 minutes, then raise the temperature to 85°C, react at this temperature for 2 hours, then cool down to 60°C, add deionized water dropwise, and control The dropping time is 1h, stirring at a constant speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com