Vertical oil pumping unit capable of achieving automatic stepless speed regulation and automatic stepless speed regulation control method of oil pumping unit

A technology of stepless speed regulation and pumping unit, which is applied to the mobile frame, engine components, engine lubrication, etc., and can solve the problem that the pumping unit cannot realize stepless speed regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

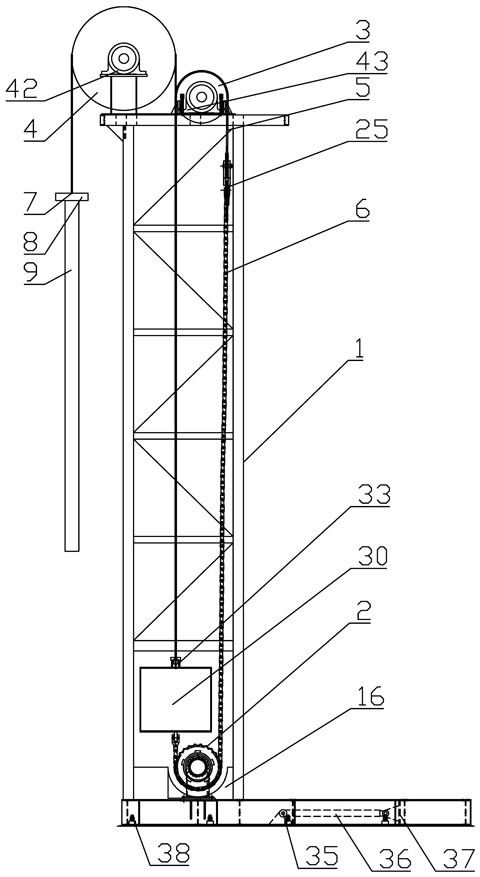

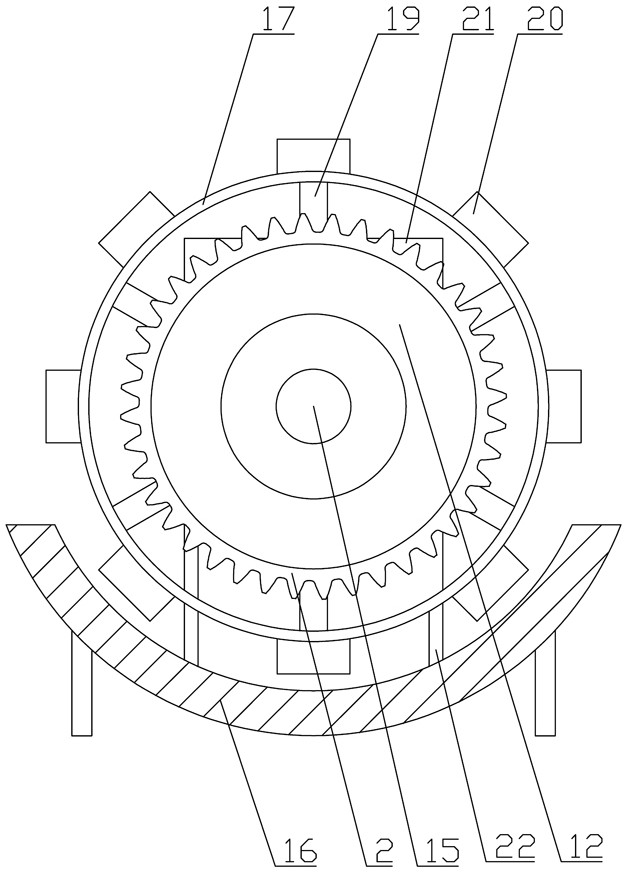

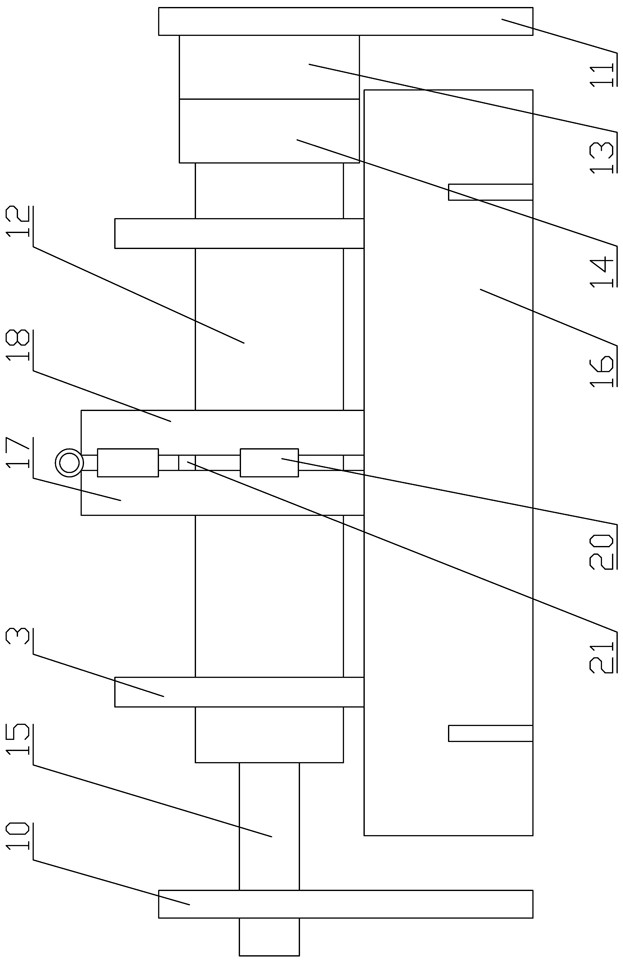

[0036] Embodiment one: as attached figure 1 , 2 . , connecting chain 6, oil pumping rope 7, rope hanger 8, the first rope chain connector, the second rope chain connector, intelligent control module and driving device, the bottom of the tower frame 1 is provided with a driving device, the output end of the driving device A sprocket 2 is fixedly installed, and the top of the tower 1 corresponding to the position above the sprocket 2 is provided with a winch 3, and the top of the tower 1 corresponding to the left position of the winch 3 is provided with a sky wheel 4, the sprocket 2, the winch 3 and The axis of the sky wheel 4 is distributed along the front and rear directions. The outer side of the lower part of the sprocket wheel 2 is provided with a U-shaped connecting chain 6 with the upper part located above it and opening upward. The lower U-shaped connecting rope 5, the outside of the upper part of the sky wheel 4 is provided with a U-shaped oil pumping rope 7 with the ...

Embodiment 2

[0048] Embodiment two: as attached figure 1 As shown, an automatic stepless speed regulation control method of the pumping unit using the above-mentioned automatic stepless speed regulation vertical pumping unit comprises the following steps:

[0049] S1: the control module controls the rotation direction, rotation speed and start / stop of the hydraulic motor 13, and the control module controls the flow rate pumped into the hydraulic motor 13 by the hydraulic station;

[0050] S2: the control module receives the rotation angle signal and the rotation direction signal of the output shaft of the hydraulic motor 13, wherein the rotation angle signal and the rotation direction signal of the output shaft of the hydraulic motor 13 are collected by an angular velocity sensor;

[0051] S3: Set the stroke s1 and stroke times on the control module;

[0052] S4: The control module calculates the starting acceleration, constant running speed and stop deceleration of the second rope chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com