Gas turbine stator blade and cooling structure thereof

A cooling technology for gas turbines and blades, which is applied to mechanical equipment, engine components, machines/engines, etc., and can solve problems such as the large influence of cooling air consumption on overall machine efficiency, difficulty in arranging cooling structures, and limitations in cooling design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0052] Below, the present invention will be further described in detail through specific embodiments in conjunction with the accompanying drawings.

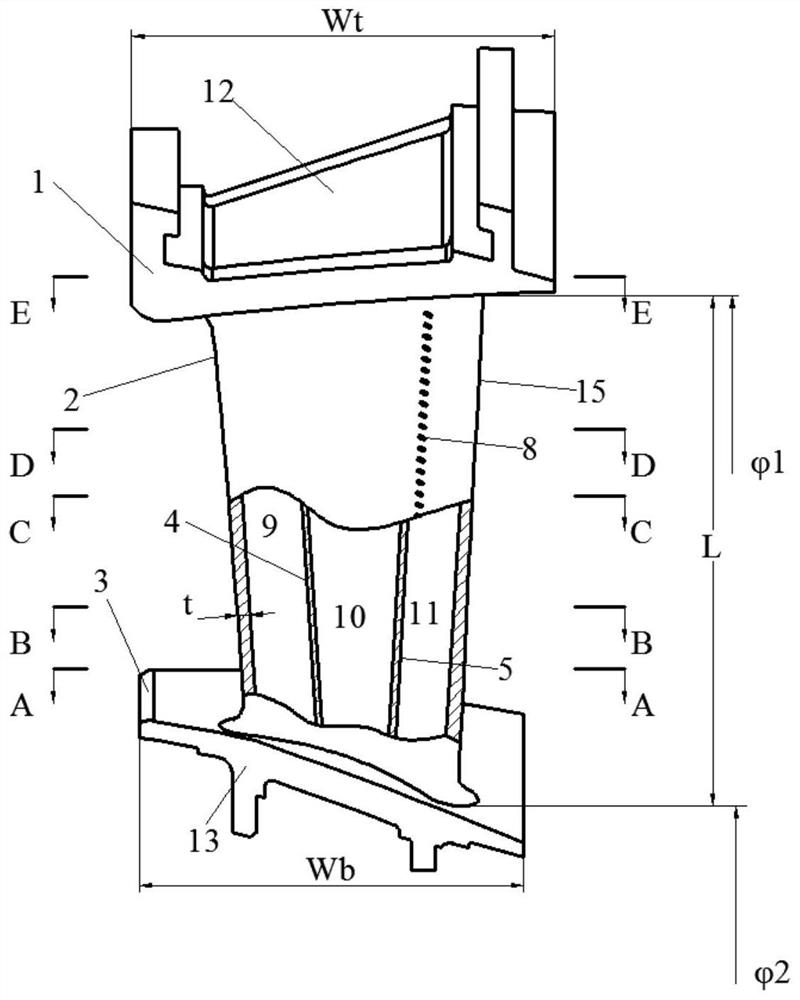

[0053] Such as Figure 1-16 As shown, the present invention provides a blade cooling structure, comprising:

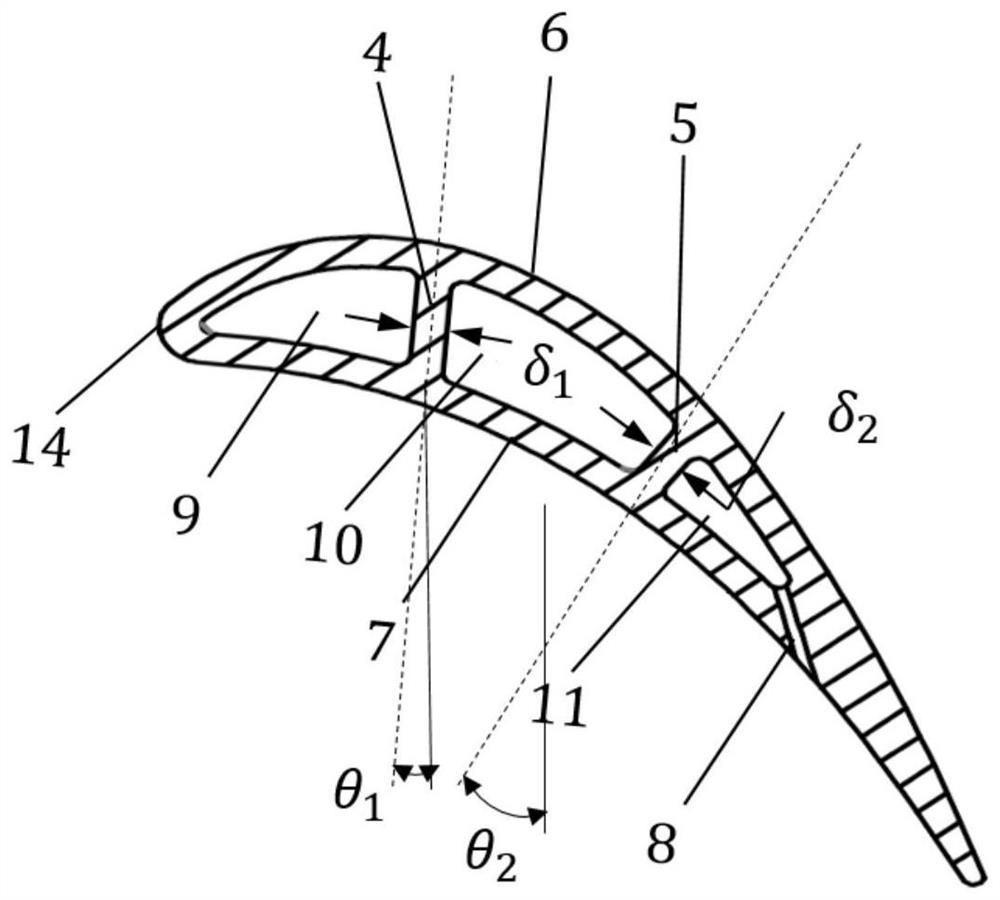

[0054] The first blade partition 4,

[0055] The second blade partition 5 spaced apart from the first blade partition 4,

[0056] The first cooling channel 9 , the second cooling channel 10 and the third cooling channel 11 divided by the first blade separator 4 and the second blade separator 5 ,

[0057] Air film holes 8 communicating with the third cooling channel 11 .

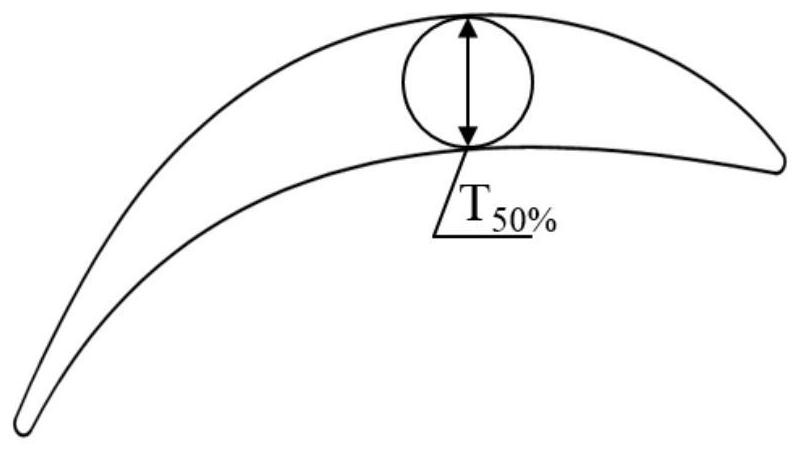

[0058] Preferably, the thickness δ of the first blade separator 4 1 The maximum thickness T of the airfoil section at 50% of the leaf height 50% The ratio range is 0.146-0.178, the draft a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com