A tapered optical fiber flow velocity sensor based on fbg written by femtosecond laser

A flow velocity sensor and femtosecond laser technology, applied in fluid velocity measurement, instruments, velocity/acceleration/impact measurement, etc., can solve the problems of unsatisfactory sensor micro-probe design, difficulty in fluid flow velocity measurement, and low starting flow velocity of the sensor, etc., to achieve Fast writing process, simple structure, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

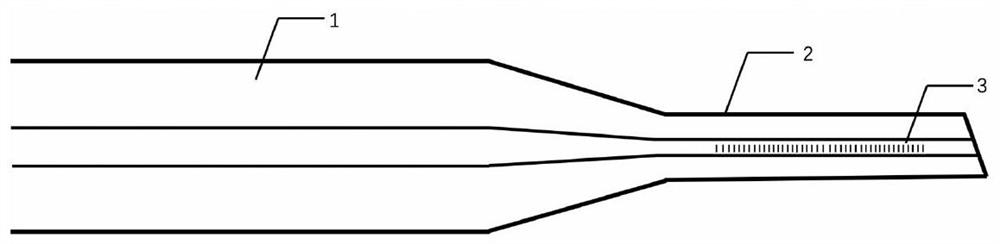

[0013] figure 1 It is a schematic diagram of the structure of the sensor head of the present invention. A tapered single-mode fiber is obtained by drawing an ordinary single-mode fiber through discharge, wherein the diameter of the tapered waist is 9-11 μm, the length of the tapered waist is 5-10 mm, and the inclination angle of the end of the tapered waist is 7.5 °-8.5°. The FBG is inscribed on the cone waist by a point-by-point method with a femtosecond laser, with a length of 2-5 mm and a Bragg wavelength of 1450-1560 nm.

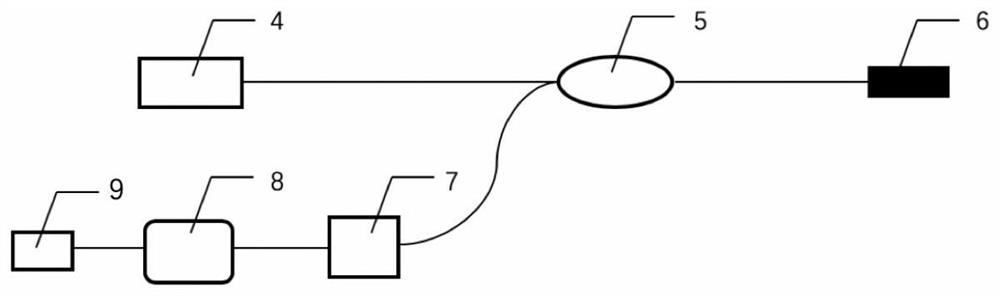

[0014] figure 2 Shown is a schematic diagram of the implementation and application system of the present invention, including a single-wavelength laser, a circulator, an optical fiber sensing head, a photodetector, an A / D data acquisition unit and a microprocessor. The detectors are respectively connected to the three ports of the circulator. The photodetector converts the collected optical signals into electrical signals, and then collects the data t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com