Visual sensor optical optimization device and correction method for outdoor complex environment

A visual sensor and complex environment technology, applied in optics, optical components, televisions, etc., can solve problems that affect system measurement reliability, thick protective glass, and inability to disperse in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

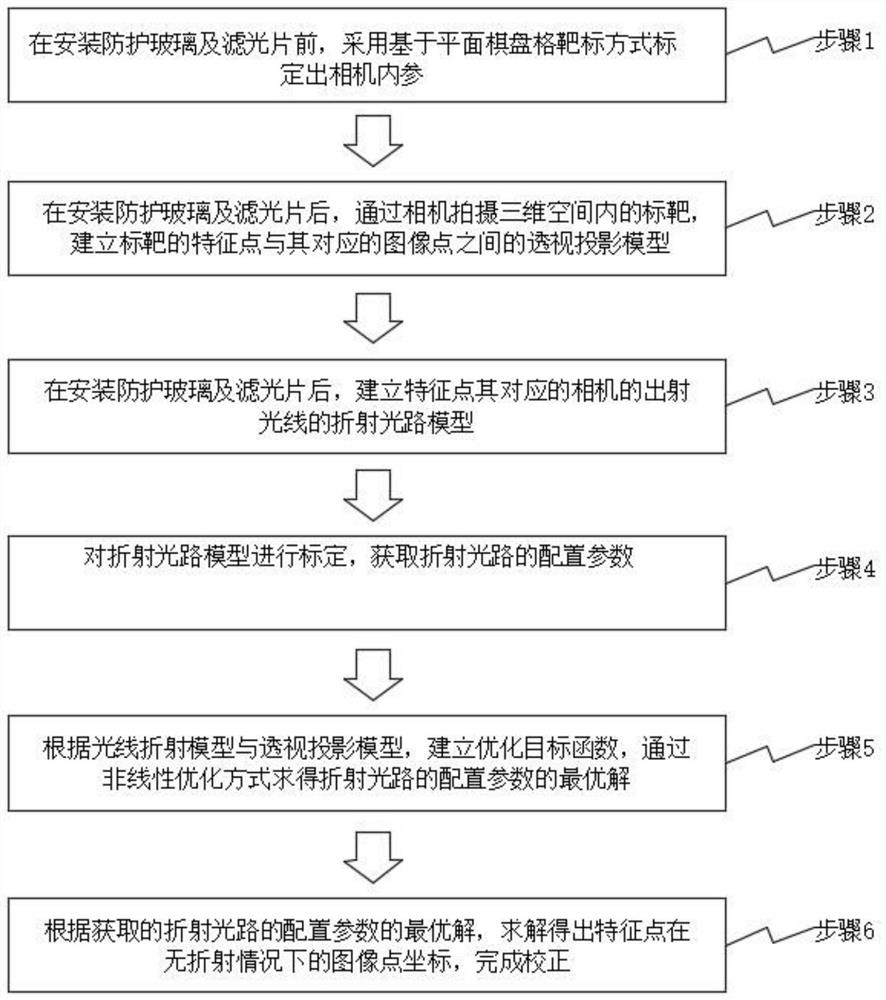

[0046] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

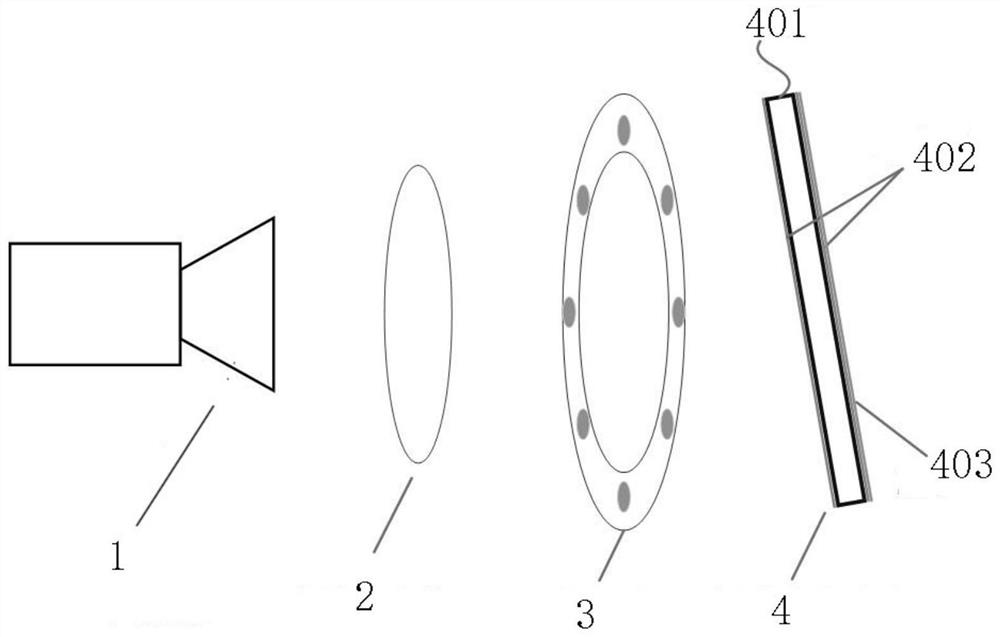

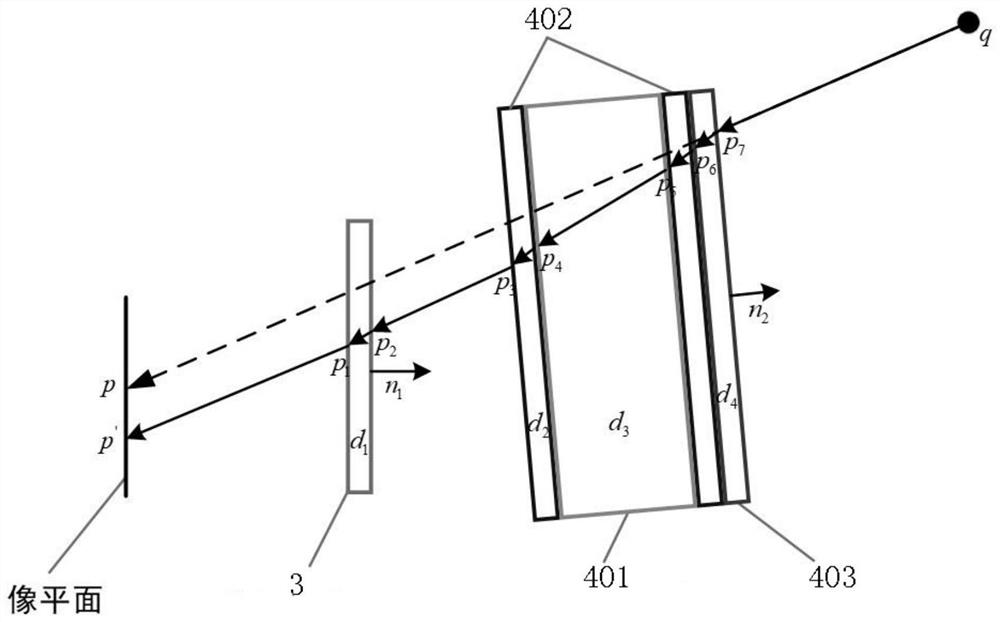

[0047] See figure 1 , a visual sensor optical optimization device for outdoor complex environments of the present invention, which is installed in the housing of the visual sensor, including the front of the camera lens 1 placed in the visual sensor, which is arranged sequentially from the image side to the object side:

[0048] Optical filter 2, in order to shield the outdoor stray light interference and improve the imaging signal-to-noise ratio of the measured target, the optical filter 2 of the visual sensor optical optimization device for outdoor complex environments in this embodiment adopts a near-infrared narrow-band filter The optical filter 2 corresponds to the wavelength of the light source 3. In this embodiment, its wavelength range is 808nm±10nm, which can effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com