Textile printing and dyeing device based on high-energy microbubble technology

A technology for textiles and microbubbles, which is applied in the configuration of equipment for processing textile materials, spraying/jetting textile materials, etc., and can solve problems such as a large amount of waste water, blockage, and environmental problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

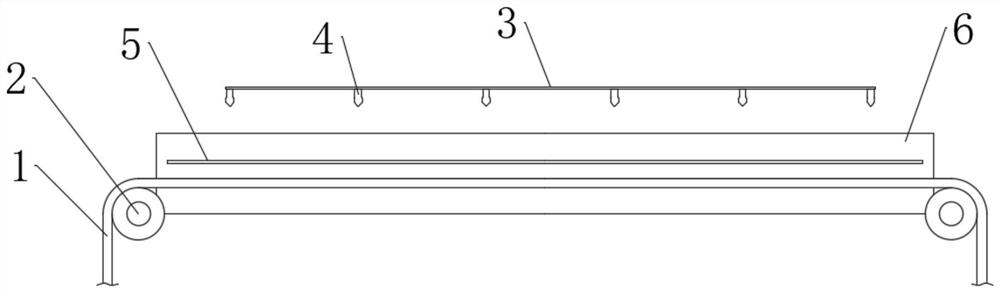

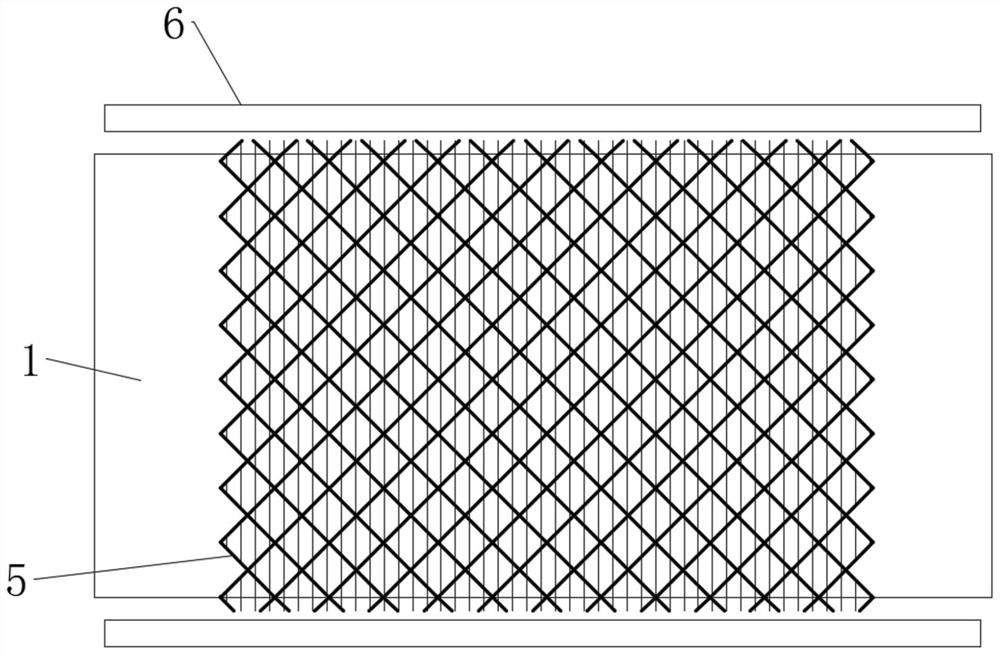

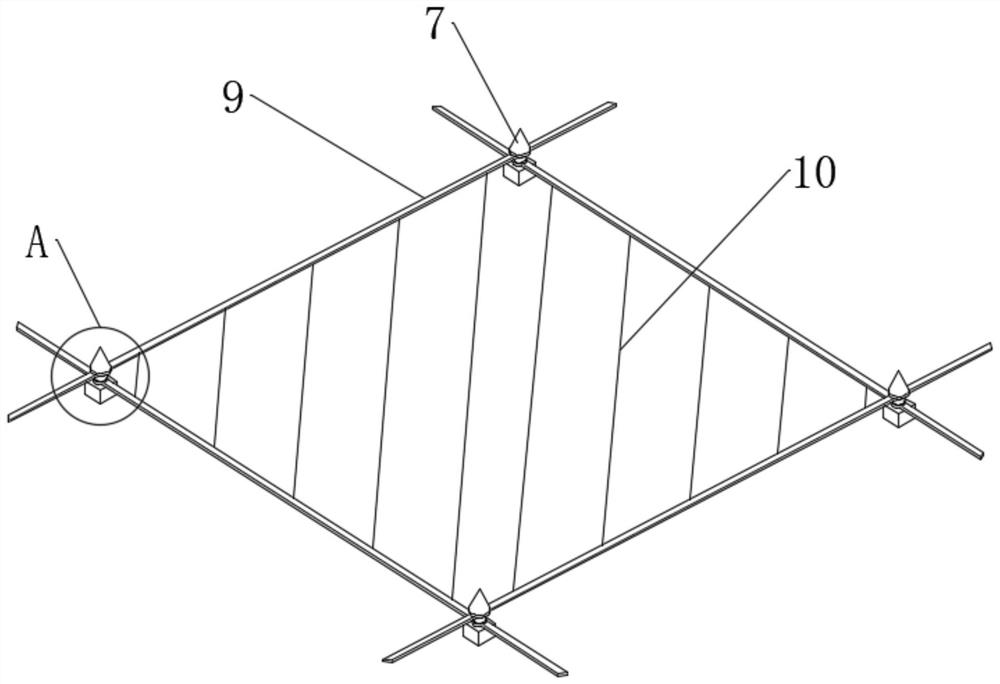

[0037] see Figure 1-2 , a textile printing and dyeing device based on high-energy microbubble technology, including a textile main body 1 and a driving roller 2, and the textile main body 1 is installed on the driving roller 2, and the textile main body 1 is always in a tensioned state, and the upper side of the textile main body 1 is set There is a nozzle frame 3, and one end of the nozzle frame 3 close to the textile body 1 is fixedly connected with a plurality of uniformly distributed high-energy microbubble nozzles 4, and the upper side of the textile body 1 is provided with a telescopic belt 5, which is located between the textile body 1 and the nozzle frame. between 3.

[0038] Among them, the driving roller 2, the nozzle frame 3 and the telescopic belt 5 of the rice in the present application are all fixedly connected to the frame respectively, and the fixed connection is realized through the frame, while the high-energy microbubble nozzle 4 is connected with the dye s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com