Control method, device and equipment for engine starting

A technology for engine start-up and control methods, which is applied in the direction of engine control, mechanical equipment, engine components, etc., and can solve the problems of increased original emissions of internal combustion engines, poor emission consistency, and high emissions of internal combustion engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

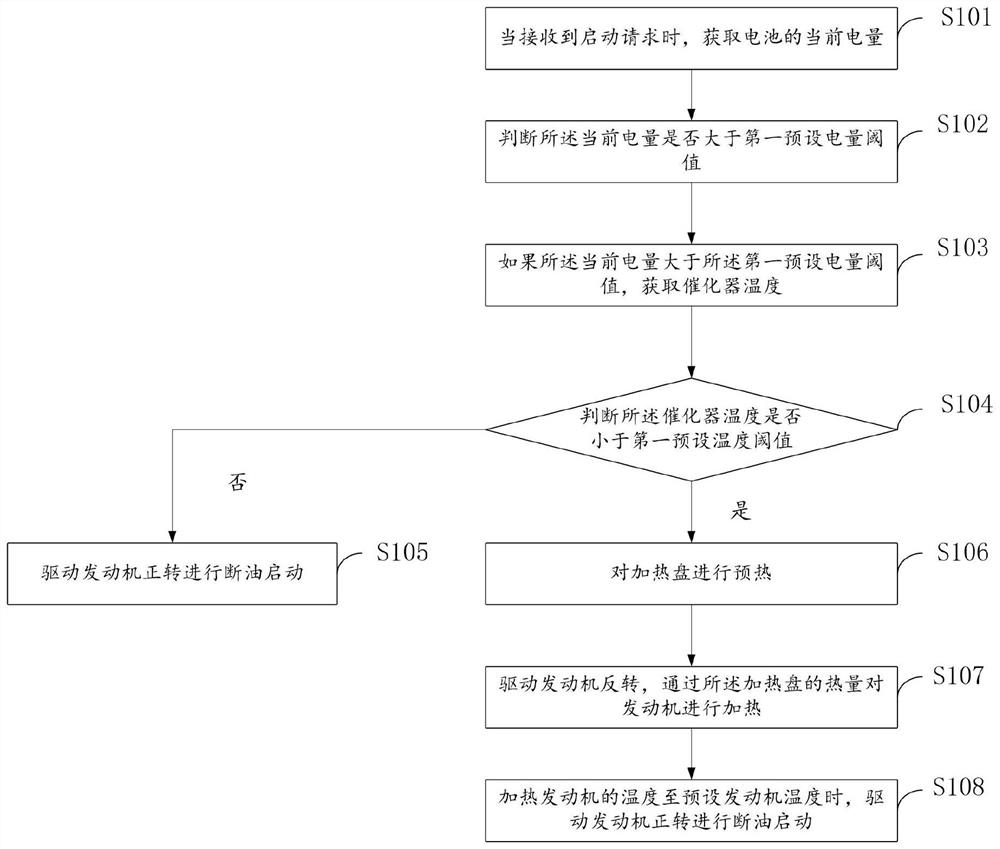

[0074] Embodiment 1 provides a control method for starting an engine, such as figure 1 shown, including the following steps:

[0075] S101. When a start request is received, obtain the current power level of the battery;

[0076] S102. Judging whether the current power is greater than a first preset power threshold;

[0077] S103. If the current electric quantity is greater than the first preset electric quantity threshold, acquire the catalyst temperature;

[0078] S104. Judging whether the temperature of the catalyst is less than a first preset temperature threshold;

[0079] S105. If the temperature of the catalytic converter is not less than the first preset temperature threshold, drive the engine forward to start with fuel cutoff;

[0080] S106. If the temperature of the catalyst is lower than the first preset temperature threshold, preheat the heating plate;

[0081] S107. Drive the engine in reverse, and heat the engine through the heat of the heating plate;

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com