Electronic component detection system and method

一种电子元件、检测系统的技术,应用在检测系统领域,能够解决电子元件无法准确插入电路板、整脚精度不足、插脚偏摆等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the various embodiments listed below, the same or similar elements or components will be denoted by the same reference numerals.

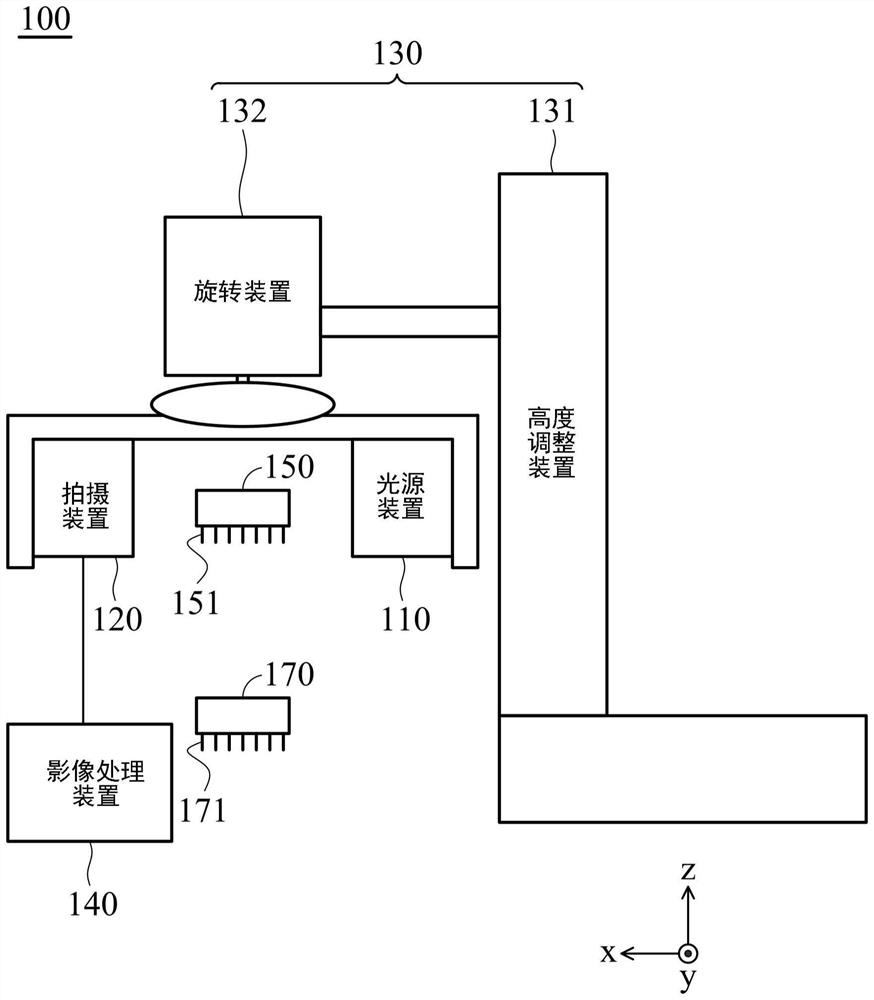

[0032] figure 1 It is a schematic diagram of an electronic component inspection system according to an embodiment of the present invention. Please refer to figure 1 The electronic component inspection system 100 includes a light source device 110 , a camera device 120 , an adjustment device 130 and an image processing device 140 . Note that, figure 1 It is only an embodiment of the present invention, but the present invention is not limited thereto. The electronic component inspection system 100 may also include other components.

[0033] In this embodiment, the light source device 110 , the photographing device 120 , and the adjustment device 130 may be configured on a mobile carrier, and the image processing device 140 may be configured on a machine platform. Wherein, the aforementioned mobile carrier is, for example, a robot arm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com