Canned wild mushroom luncheon meat process and formula

A technology of canned luncheon meat and wild mushrooms, applied in food science, food ingredients as color, application, etc., can solve problems such as too simple meat processing, inadequate control of temperature and sterile environment, and ratio deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

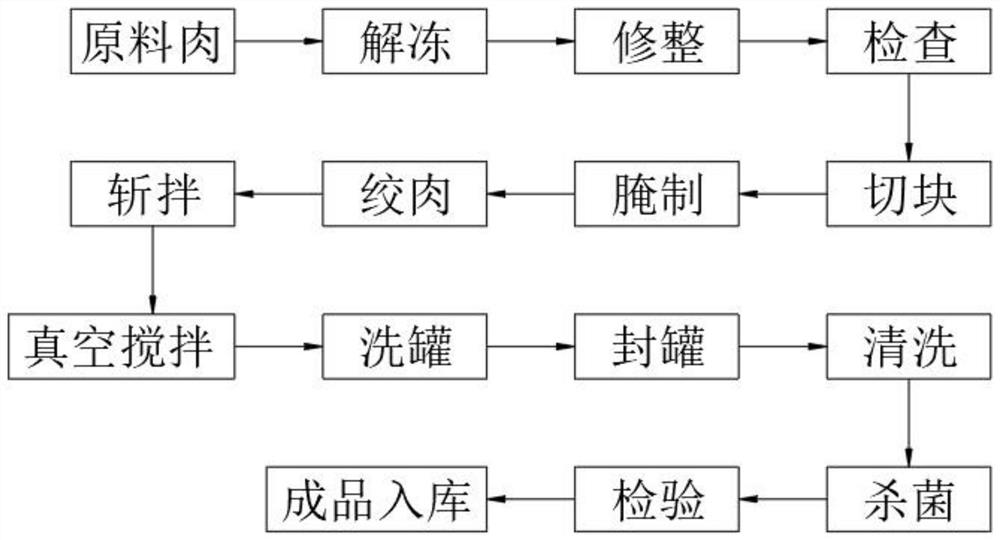

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Thaw, take out the frozen lean lean meat and fat lean meat from the cold storage, and put them in a constant temperature thawing room for thawing, the thawing temperature of lean lean meat and fat lean meat is 6°C;

[0033] Step 2: Trimming, trimming lean lean meat and fat lean meat after thawing, removing broken bones, cartilage, lymph, blood vessels, tendons, thick tissue membranes, congested meat, etc. in lean lean meat and lean meat The fat content in the medium is 6%, and the fat content in the fat and lean meat is 57%. The trimmed lean lean meat and fat lean meat are weighed, so that the proportions of lean lean meat and fat lean meat are 49.7% and 29.8% respectively;

[0034] Step 3: Check, carefully inspect the trimmed lean lean meat and fat lean meat to ensure that the trimmed meat has no bones, no hair, and no impurities before cutting into pieces;

[0035] Step 4: Cut into pieces, cut lean lean meat and fat lean meat into small pieces of 3-5 cm square...

Embodiment 2

[0048] Step 1: Thaw, take out the frozen lean lean meat and fat lean meat from the cold storage, and put them in a constant temperature thawing room for thawing, the thawing temperature of lean lean meat and fat lean meat is 6°C;

[0049] Step 2: Trimming, trimming lean lean meat and fat lean meat after thawing, removing broken bones, cartilage, lymph, blood vessels, tendons, thick tissue membranes, congested meat, etc. in lean lean meat and lean meat The fat content in the medium is 6%, and the fat content in the fat and lean meat is 57%. The trimmed lean lean meat and fat lean meat are weighed, so that the proportions of lean lean meat and fat lean meat are 49.7% and 29.8% respectively;

[0050] Step 3: Check, carefully inspect the trimmed lean lean meat and fat lean meat to ensure that the trimmed meat has no bones, no hair, and no impurities before cutting into pieces;

[0051] Step 4: Cut into pieces, cut lean lean meat and fat lean meat into small pieces of 3-5 cm square...

Embodiment 3

[0064] Step 1: Thawing, take out the frozen lean lean meat and fat lean meat from the cold storage, and put them in a constant temperature thawing room for thawing, the thawing temperature of lean lean meat and fat lean meat is 7°C;

[0065] Step 2: Trimming, trimming lean lean meat and fat lean meat after thawing, removing broken bones, cartilage, lymph, blood vessels, tendons, thick tissue membranes, congested meat, etc. in lean lean meat and lean meat The fat content in the medium is 6%, and the fat content in the fat and lean meat is 57%. The trimmed lean lean meat and fat lean meat are weighed, so that the proportions of lean lean meat and fat lean meat are 49.7% and 29.8% respectively;

[0066] Step 3: Check, carefully inspect the trimmed lean lean meat and fat lean meat to ensure that the trimmed meat has no bones, no hair, and no impurities before cutting into pieces;

[0067] Step 4: Cut into pieces, cut lean lean meat and fat lean meat into small pieces of 3-5 cm squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com