Foaming composition and preparation method and application thereof

A composition and mixture technology, applied in the field of daily necessities, can solve problems such as cracking, impermanence, and affecting the foam performance of foaming agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

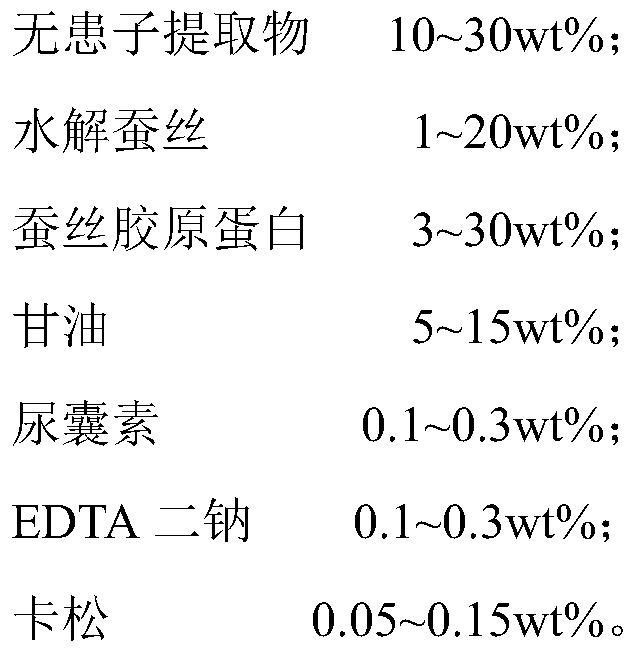

[0023] The present embodiment provides a kind of personal care product composition, and the concrete composition of this composition is as shown in table 1 below:

[0024] Table 1. Components of the composition of toilet care products

[0025] raw material Content (wt%) Deionized water 34.555 Sapinberry Extract 25 Silk Collagen 20 Hydrolyzed silk 10 glycerin 10 Allantoin 0.15 Disodium EDTA 0.2 Casson 0.095

[0026] The preparation method of this toiletry product composition is as follows:

[0027] (1) Weigh the deionized water, glycerin, allantoin, and disodium EDTA according to the above formula, add them into the reaction pot, turn on the heating equipment and stir slowly, and control the temperature at 80-85°C. After the material body is completely dissolved, the first mixture is formed, and the temperature is lowered and cooled after being kept for 15 minutes.

[0028] (2) When the first mixture is cooled to ...

Embodiment 2

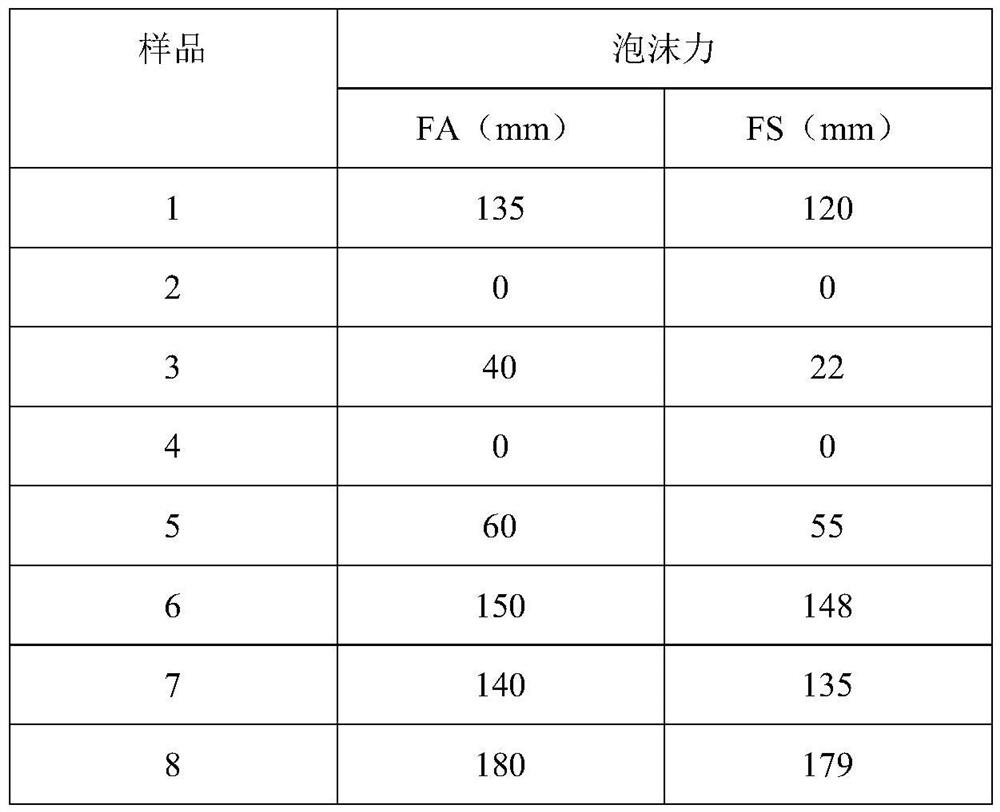

[0031] Foaming performance experiment of different foaming compositions

[0032] Prepare the corresponding foaming composition, water and Cathone mixture according to Table 2, and test its foaming power. The specific method is as follows: use the Ross-Miles method to measure the foam strength at 40±1°C. First, put 50mL of the foaming composition in the foam meter, then pour 200mL of the test solution vertically from the top of the foam meter, generate foam by impacting the solution inside the foam meter, record the initial and 5min foam heights respectively, and the initial height of the meter is characterized Foaming property FA (mm), foam stability FS (mm) is characterized by the foam height at 5 minutes, and the average value of three times is used as the foam force of the test solution.

[0033] Table 2. Composition of Foaming Compositions

[0034] the case 1 2 3 4 5 6 7 8 Deionized water 74.905 69.905 72.905 72.905 74.405 69.905 69.905 64....

Embodiment 3

[0048] Conditioning Efficacy Testing of Toiletry Compositions

[0049]Conditioning effect means that after using the product, the skin and hair can become soft and silky. Because the hair can more visually express the conditioning properties of the washing composition. Therefore, this experiment chooses hair as the research object. The test method is as follows:

[0050] Hair bundle combing power test: by performing a dry combing test on the cleaning composition, the reduction rate of combing power before and after using the cleaning composition in a dry state is compared. The testing instrument is MTT175 miniature tension tester, and the hair bundle used for testing is damaged hair quality, the hair bundle weighs 16g, is 23.5cm long, and 5.5cm wide. First test the dry combing ability of each hair bundle before using the sample, then take 1.5g sample and apply it evenly on the hair bundle, massage for 10 minutes, then rinse the hair according to the normal procedure, dry th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com