Electronic part machining machine

A technology for electronic parts and processing machines, applied in electrical components, circuits, conveyor objects, etc., can solve the problems of increased cost, difficult quality control, large use, and occupation of factory area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

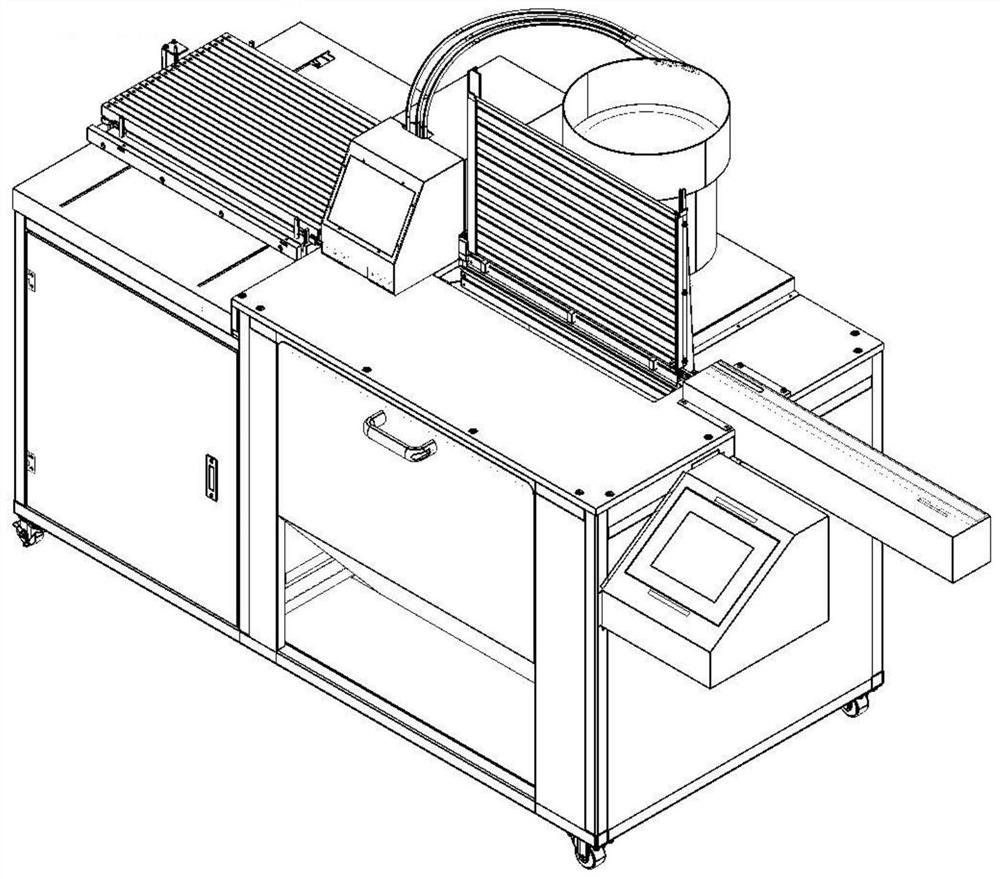

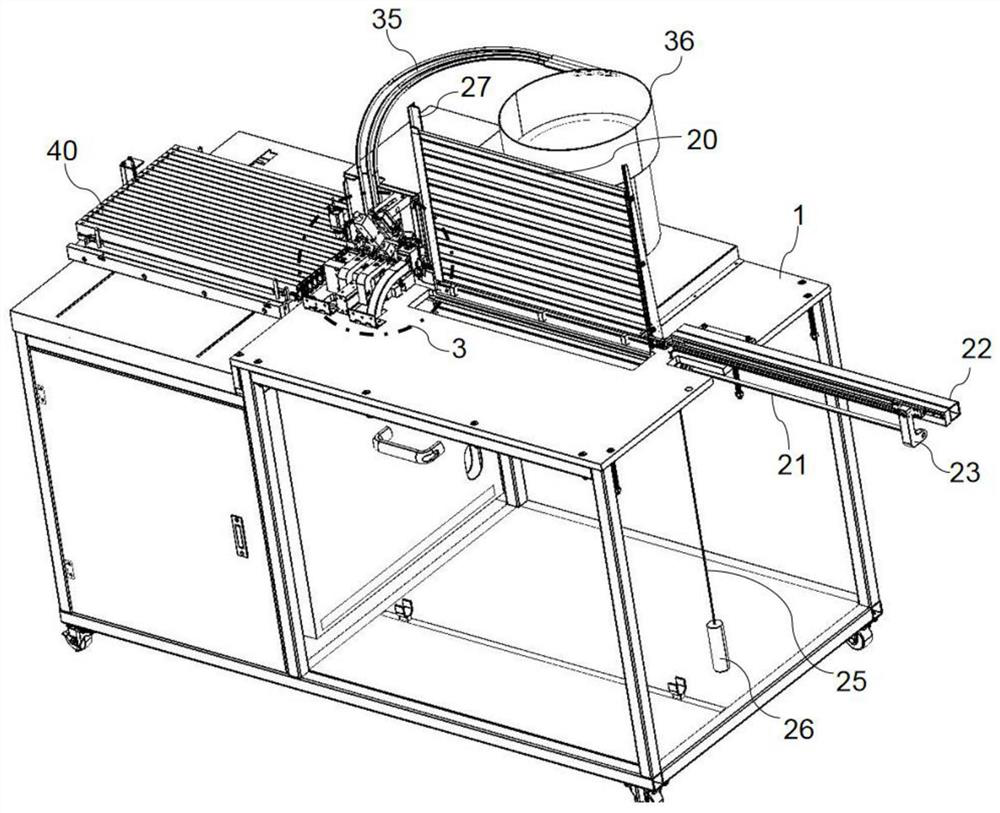

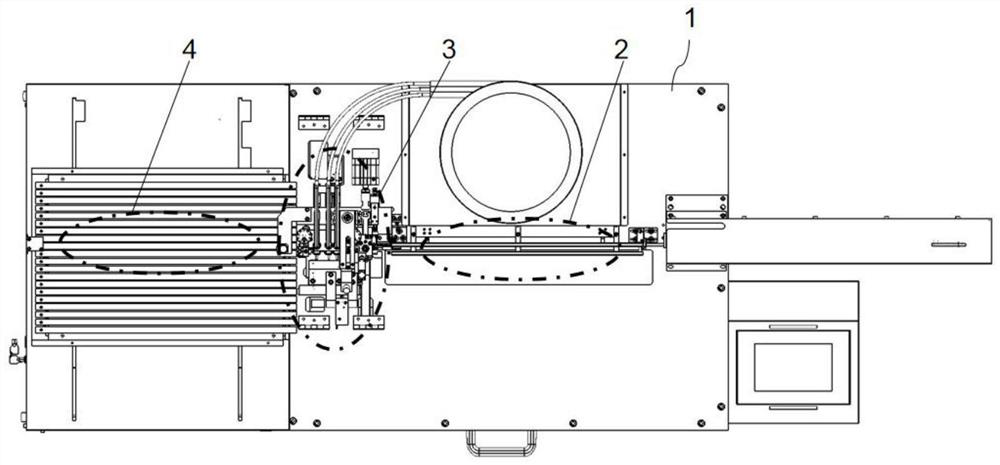

[0033] Such as Figure 1 to Figure 9 As shown, an electronic parts processing machine includes a base surface 1 and a plurality of components 5, and the base surface 1 is provided with a feeding mechanism 2, a processing mechanism 3 and a receiving mechanism 4 in sequence; the feeding mechanism 2 includes several strip-shaped hollow Feed pipe 20, the cross section of feed pipe 20 is the same as the cross section of element 5, elements 5 are arranged in the feed pipe 20 in sequence, and the feed pipe 20 is stacked up and down successively; the two ends of the feed pipe 20 are provided with feeding Pipe guide rail 27, the lower end of feed pipe guide rail 27 joins with base surface 1; The inboard of feed pipe guide rail 27 is provided with slide groove along vertical direction, and the two ends of feed pipe 5 are embedded in the slide groove, and feed pipe 5 can reciprocate up and down; the base surface 1 is also provided with a guiding block, the upper surface of the guiding bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com