Laser marking and camera detection system based on Internet of things

A technology of laser marking and detection system, applied in the field of laser marking and camera detection system, can solve the problems of low efficiency of marking time, sudden increase of air pressure, and unfavorable long-term work of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

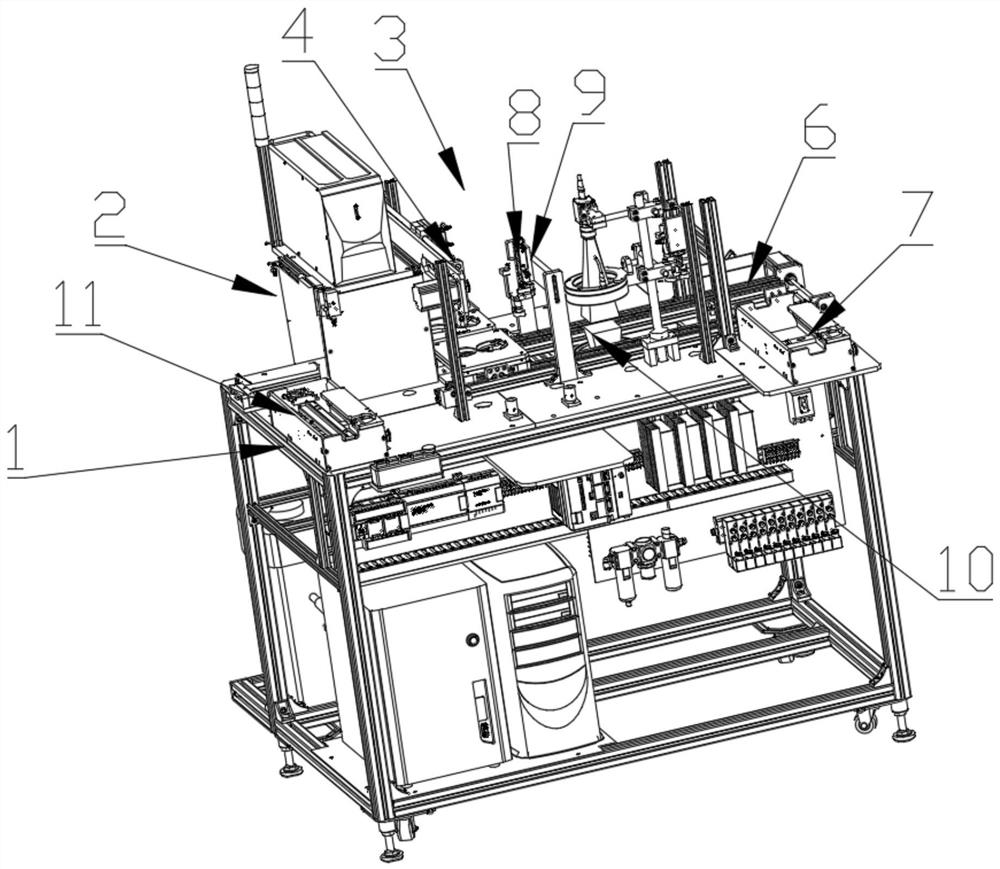

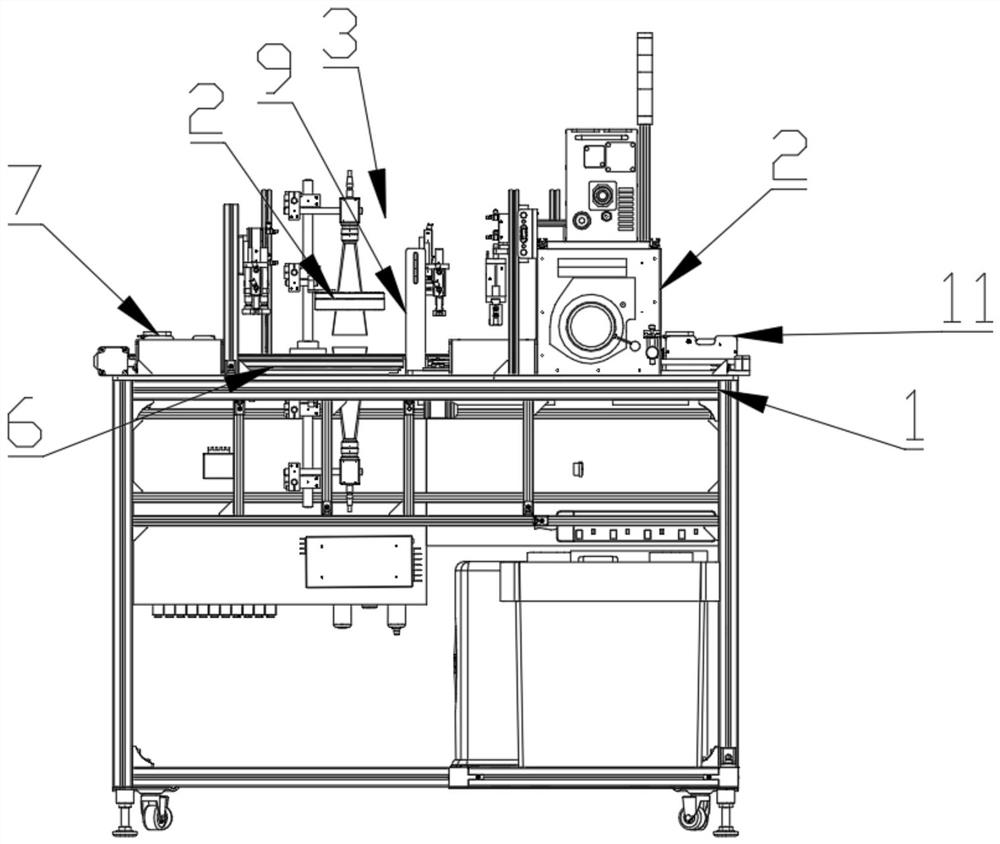

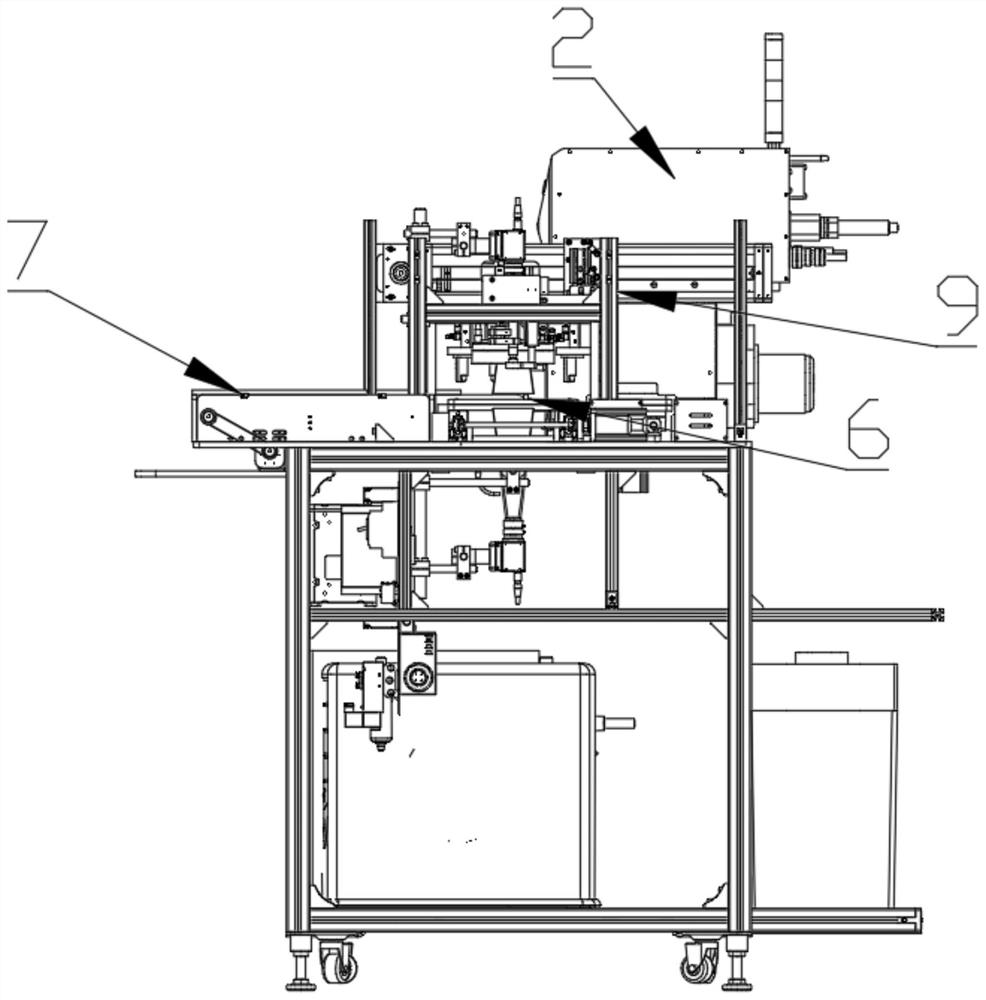

[0029]Embodiment 1: A laser marking and camera detection system based on the Internet of Things, the automatic assembly machine includes a body 1, a transport device, a marking device 2, a detection device 3, a limit device, a protection device, a dust removal device 5 and The controller, the transportation device is used to transport the product 10 and transport it under the protection of the limiting device; the marking device 2 is configured to mark the position of the product 10 being righted; the limiting device It is configured to adjust the position of the product 10; the detection device 3 is configured to detect the processing quality of the product 10 marked by the marking device 2; the dust removal device 5 is configured to The dust generated in the body 1 is recovered; the marking device 2 includes a first laser probe, several auxiliary probes, an offset mechanism, a lifting mechanism and a support base, and the support base is configured to support each of the The...

Embodiment 2

[0030] Embodiment 2: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis of it. Specifically, a laser marking and camera detection system based on the Internet of Things is provided. The automatic assembly machine includes a body 1, a transport device, a marking device 2, a detection device 3, a limit device, a protection device, a dust removal device 5 and a controller. Transport under the protection of the positioning device; the marking device 2 is configured to mark the position of the product 10 that is being righted; the limiting device is configured to adjust the position of the product 10; the detection device 3 is It is configured to detect the processing quality of the product 10 marked by the marking device 2; the dust removal device 5 is configured to recover the smoke generated in the body 1; specifically, in this embodiment Among them, the transportatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com