Intelligent perpendicular spiral bagging device and control method

A technology of vertical spiral and bagging device, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of high material level in the bag, large weighing error, and material overflowing the packaging bag, and achieve high-efficiency packaging. Realize the effect of intelligent control and stable packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

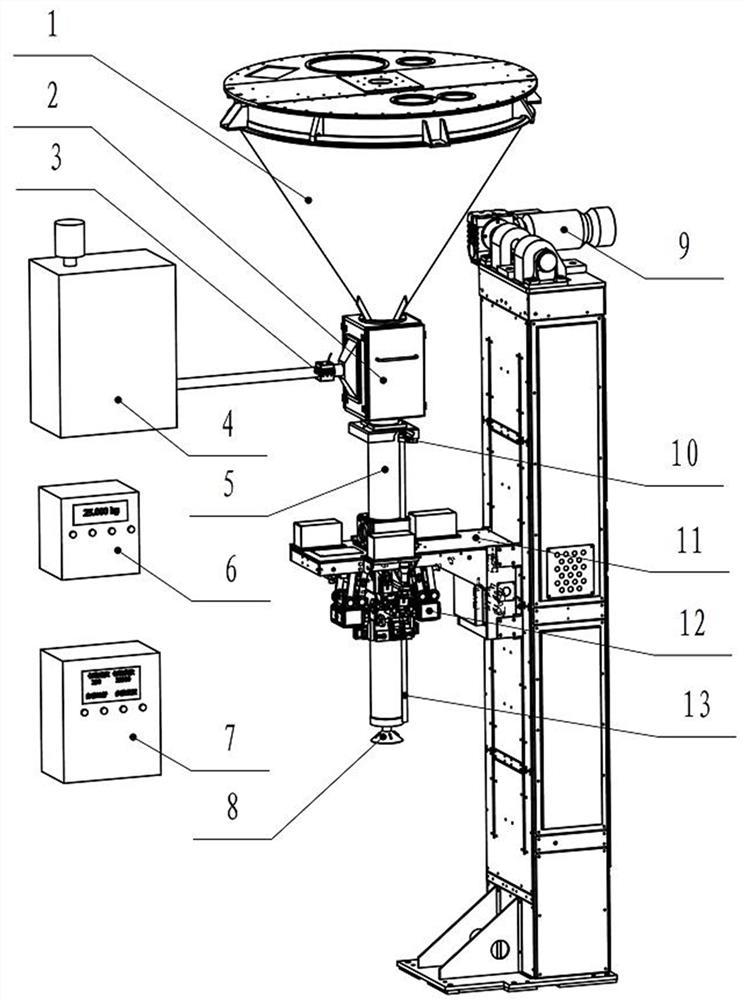

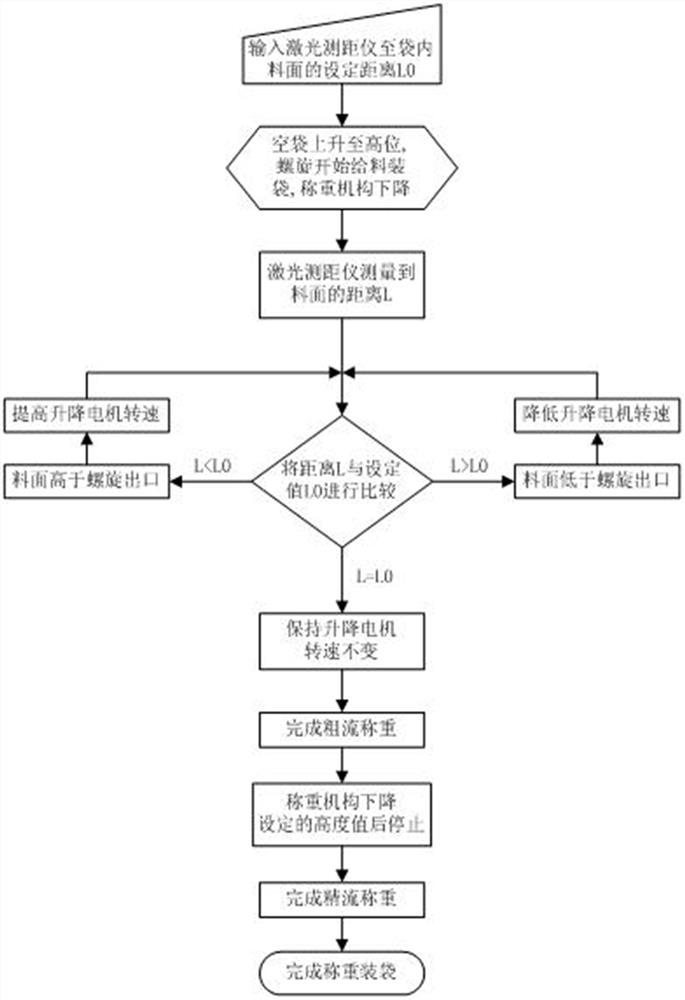

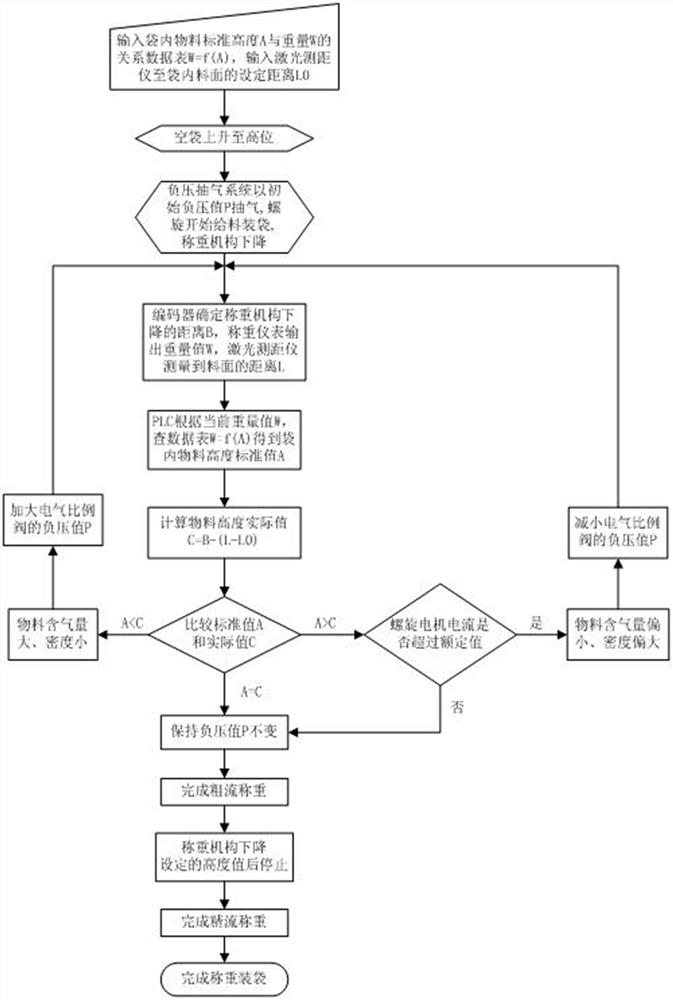

[0028] The specific embodiment of the present invention sees Figure 1 to Figure 3 , an intelligent vertical spiral bagging device, which includes a storage hopper 1, the lower end of the storage hopper 1 is connected to an air extraction barrel 2, the lower end of the air extraction barrel 2 is connected to an inner barrel, and a feeding screw 8 is arranged inside the inner barrel, The feeding screw 8 is driven by a motor, and the lifting outer cylinder 5 is also provided under the pumping cylinder 2. A laser rangefinder 10 is arranged on the outer upper end of the lifting outer cylinder 5. The lower end of the laser rangefinder 10 is connected to a beam tube 13, and the beam The outlet of the lower end of the tube 13 is near the outlet of the feeding screw 8, the beam of the laser rangefinder 10 is irradiated downward in the beam tube 13, the lifting outer cylinder 5 passes through the middle of the weighing mechanism 12, and the weighing mechanism 12 is fixed on the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com