Refined boric acid preparation device for chemical engineering

A preparation device, boric acid technology, applied in boron oxyacids, inorganic chemistry, boron compounds, etc., can solve the problems of boric acid residue waste, inability to wash and separate impurities, inability to separate solids and liquids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

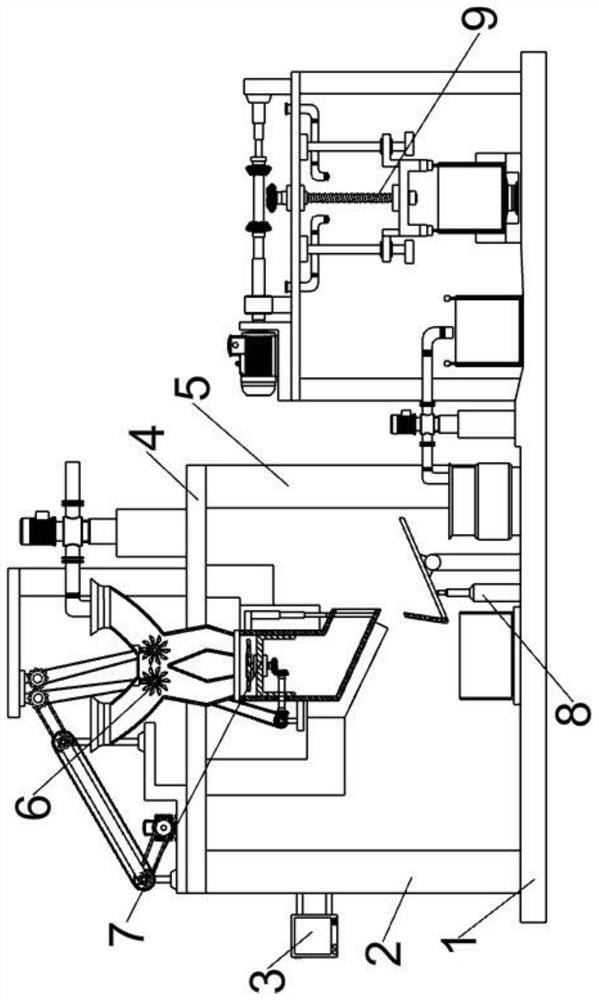

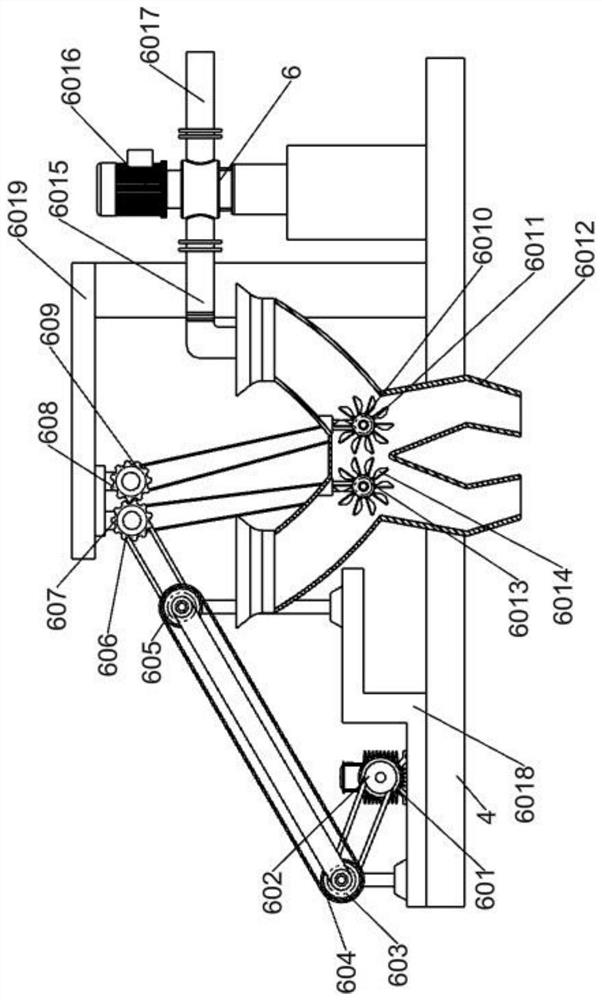

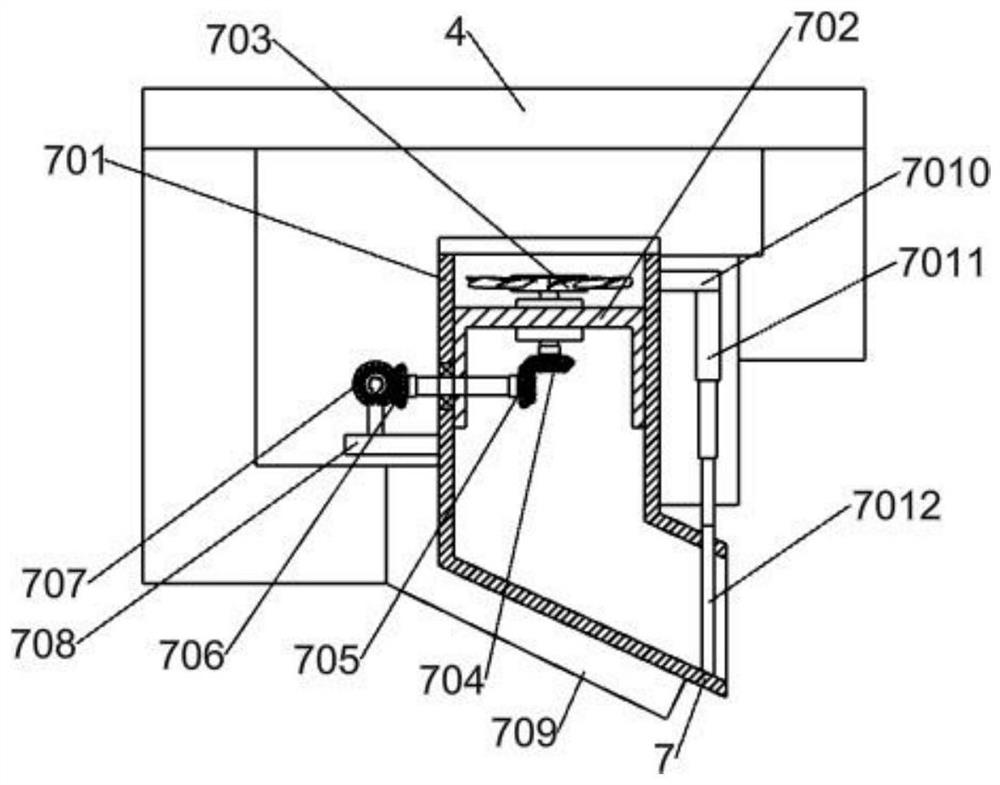

[0029] A kind of refined boric acid preparation device for chemical industry, such as Figure 1-7 As shown, it includes a working machine base plate 1, a first high column 2, an operation monitoring control panel 3, a first high working plate 4, a second high column 5, a slag washing mechanism 6, a mixing and soaking mechanism 7, and a filter heat filter. Dissolving mechanism 8 and boric acid precipitation washing mechanism 9; The left side of the bottom plate of the working machine 1 is welded with the first high column 2; The boric acid precipitation and washing mechanism 9 is connected; the middle and upper part of the left end of the first high column 2 is provided with an operation monitoring control panel 3; the top of the first high column 2 is bolted to the first high work plate 4; the first high work plate The right side of the bottom of 4 is bolted to the second high column 5, and the bottom of the second high column 5 is connected to the bottom plate 1 of the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com