High-viscosity modified asphalt for water-permeable pavement and preparation method thereof

A water-permeable pavement and modified asphalt technology, which is applied in the field of asphalt materials, can solve the problems of unsatisfactory asphalt, achieve the effects of weight reduction, high structural strength, improvement of high temperature stability and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

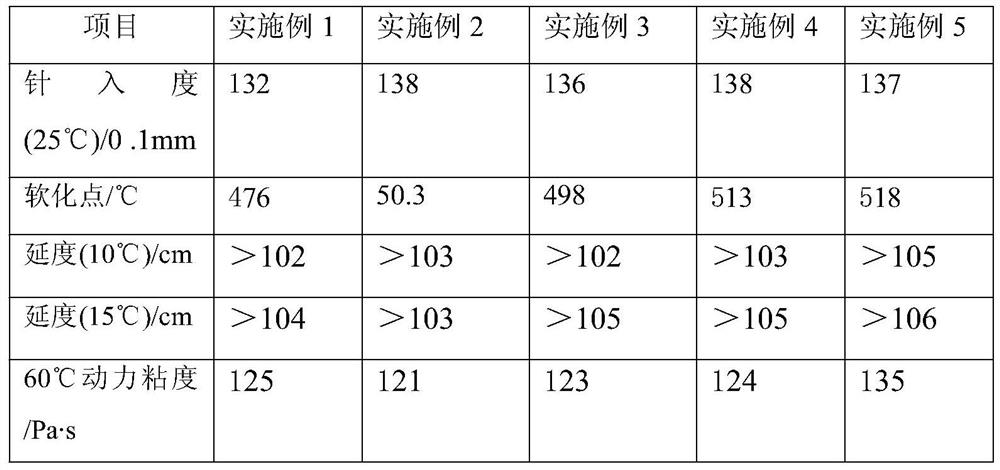

Examples

Embodiment 1

[0056]The first component is prepared, the asphalt is mixed with UV absorber and dispersant, then heated to 180°C through a heat exchanger, transferred to the mixing production tank, and transferred to the mixing production tank; the second component is prepared, using the existing concrete Block preparation of raw materials, specifically: select waste concrete blocks, add them to a high-temperature furnace, and continue to process them at 130°C for 35 minutes; put the waste concrete blocks treated in the previous steps into a mixer, and continuously feed them into the mixer High-pressure air is used to crush the waste concrete blocks inside to obtain waste gas concrete powder; the preparation of permeable concrete is specifically: according to the weight fraction, 40 parts of waste gas concrete powder, 8 parts of water glass, and 8 parts of fine aluminum powder 8 parts, 8 parts of bentonite, 8 parts of gypsum, 8 parts of quicklime, and 25 parts of fine river sand are put into ...

Embodiment 2

[0058] The first component preparation, the asphalt is mixed with UV absorber and dispersant, then heated to 170°C through a heat exchanger, transferred to the mixing production tank, and transferred to the mixing production tank; the second component preparation, using the existing concrete Block preparation raw materials, specifically: select waste concrete blocks, add them to a high-temperature furnace, and continue to process them at 120°C for 30 minutes; put the waste concrete blocks treated in the previous steps into a mixer, and continuously feed them into the mixer High-pressure air is used to crush the waste concrete blocks inside to obtain waste gas concrete powder; the preparation of permeable concrete is specifically: according to the weight fraction, 30 parts of waste gas concrete powder, 5 parts of water glass, and 5 parts of fine aluminum powder 5 parts of bentonite, 5 parts of gypsum, 5 parts of quicklime, and 20 parts of fine river sand are put into the mixer a...

Embodiment 3

[0060] The first component is prepared, the asphalt is mixed with UV absorber and dispersant, then heated to 190°C through a heat exchanger, transferred to the mixing production tank, and transferred to the mixing production tank; the second component is prepared, using the existing concrete Block preparation raw materials, specifically: select waste concrete blocks, add them to a high-temperature furnace, and continue to process them at 150°C for 45 minutes; put the waste concrete blocks treated in the previous steps into a mixer, and continuously feed them into the mixer High-pressure air is used to crush the waste concrete blocks inside to obtain waste gas concrete powder; the preparation of permeable concrete is specifically: according to the weight fraction, 50 parts of waste gas concrete powder, 10 parts of water glass, and 10 parts of fine aluminum powder 10 parts of bentonite, 10 parts of gypsum, 10 parts of quicklime, and 30 parts of fine river sand are put into the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com